Lead screw drive gear meshing clutch with self-locking function

A technology of transmission teeth and clutches, applied in the field of clutches, can solve the problems of being unsuitable for space robots, and the electromagnetic clutch has a small carrying capacity, and achieves the effect of simplifying the design of the mechanism, reducing the mass, and having a large load capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

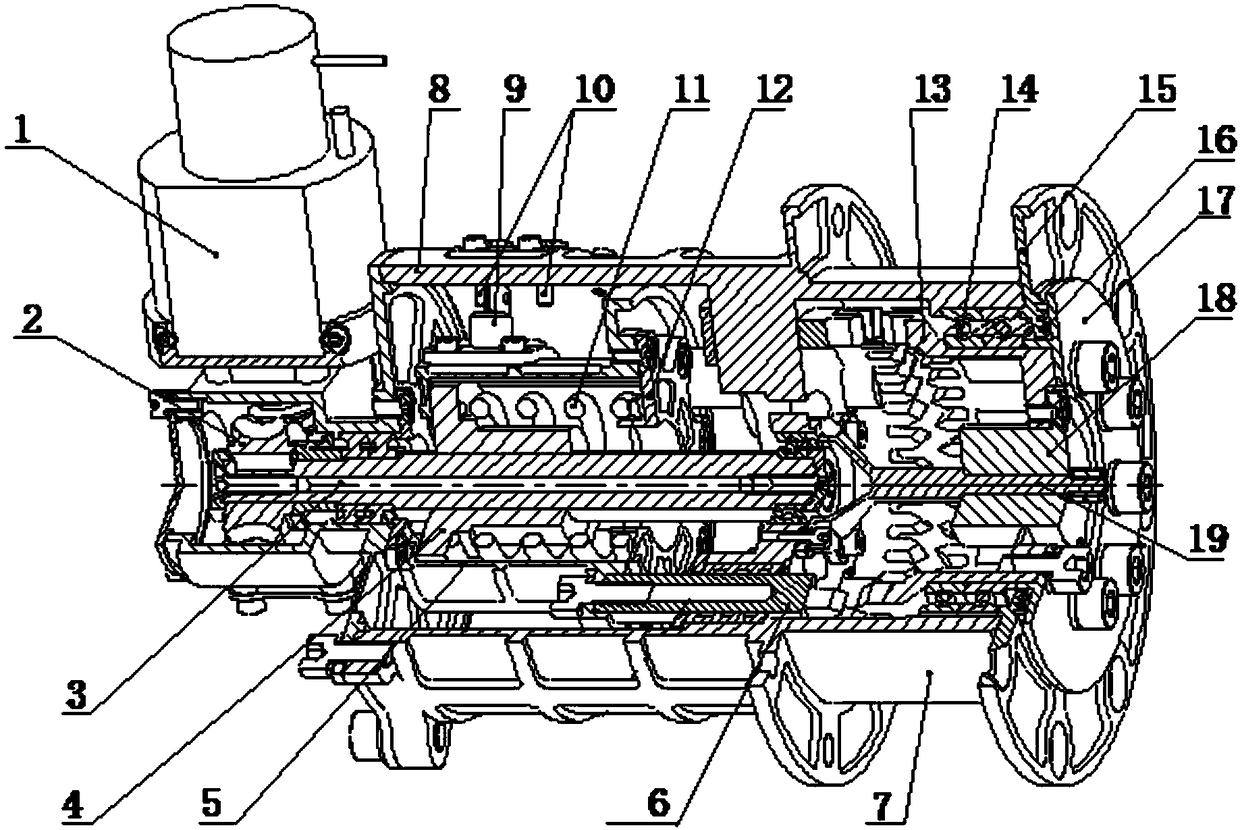

[0016] See attached figure 1 , a screw-driven gear meshing clutch with self-locking function, which includes: a motor 1, a housing 8, a ball screw 3 installed in the housing 8, fixed teeth 6 and movable teeth 13. Wherein the fixed tooth 6 is an external gear, and the movable tooth 13 is an internal gear.

[0017] The output shaft of the motor 1 is connected to the ball screw 3 through the worm gear 2, and the ball screw 3 is provided with a screw nut 4, and the screw nut 4 is sleeved with a compression spring 11 pre-tightened by a compression spring end cover 12, and the compression spring One end of 11 is in conflict with the shoulder of the lead screw nut 4, and the other end is in conflict with the fixed tooth bracket 5, so that the fixed tooth bracket 5 and the lead screw nut 4 are flexibly connected through the compression spring 11, and the fixed tooth 6 and the fixed tooth bracket 5 fixed connections.

[0018] The movable tooth 13 is installed in the housing 8 through...

Embodiment 2

[0022] The resolver shaft 19 is added on the basis of the above-mentioned embodiment 1, specifically: the resolver shaft 19 is installed in the housing 8, and a resolver for measuring the rotation angle of the movable tooth 13 relative to the housing 8 is installed on the resolver shaft 19 device 18; when the fixed teeth 6 and the movable teeth 13 are disconnected and not meshed, the movable teeth 13 can rotate freely inside the housing 8; the rotation angle of the movable teeth 13 relative to the housing 8 is measured by the resolver 19.

Embodiment 3

[0024] Furthermore, the fixed tooth bracket 5 is provided with a limit switch plate 9, and the inner circumferential surface of the housing 8 is provided with a limit switch column 10 in the direction of motion of the fixed tooth bracket 5; movement, when the fixed teeth 6 and the movable teeth 13 are fully meshed, the limit switch piece 9 contacts the right column of the limit switch column 10, and a limit signal is generated, which indicates that the clutch has been fully engaged. Motor 1 is de-energized. During the separation process of the clutch, the fixed tooth bracket 5 moves to the left. When the fixed tooth 6 and the movable tooth 13 are completely disconnected and the fixed tooth bracket 5 continues to run to the left for a certain distance, the limit switch plate 9 and the limit switch column 10 The left column contact of the left side generates a limit signal, which indicates that the clutch has been completely disengaged, and the motor 1 is de-energized at this ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com