A distributed high-efficiency energy-saving phase change heat storage system

A phase-change heat storage, high-efficiency and energy-saving technology, applied in heating systems, solar thermal energy, heating methods, etc., can solve the problems of reduced energy utilization, no recycling, etc., to save electricity costs, easy to take and release heat, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

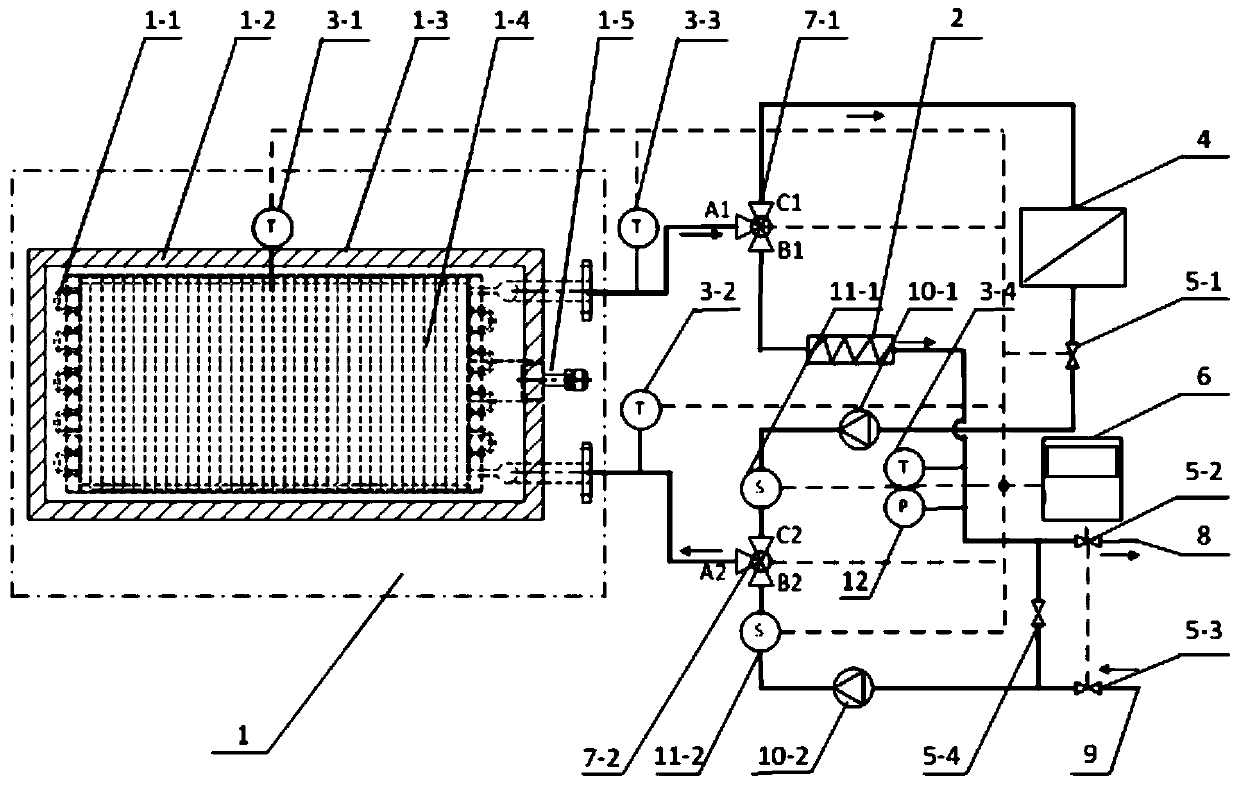

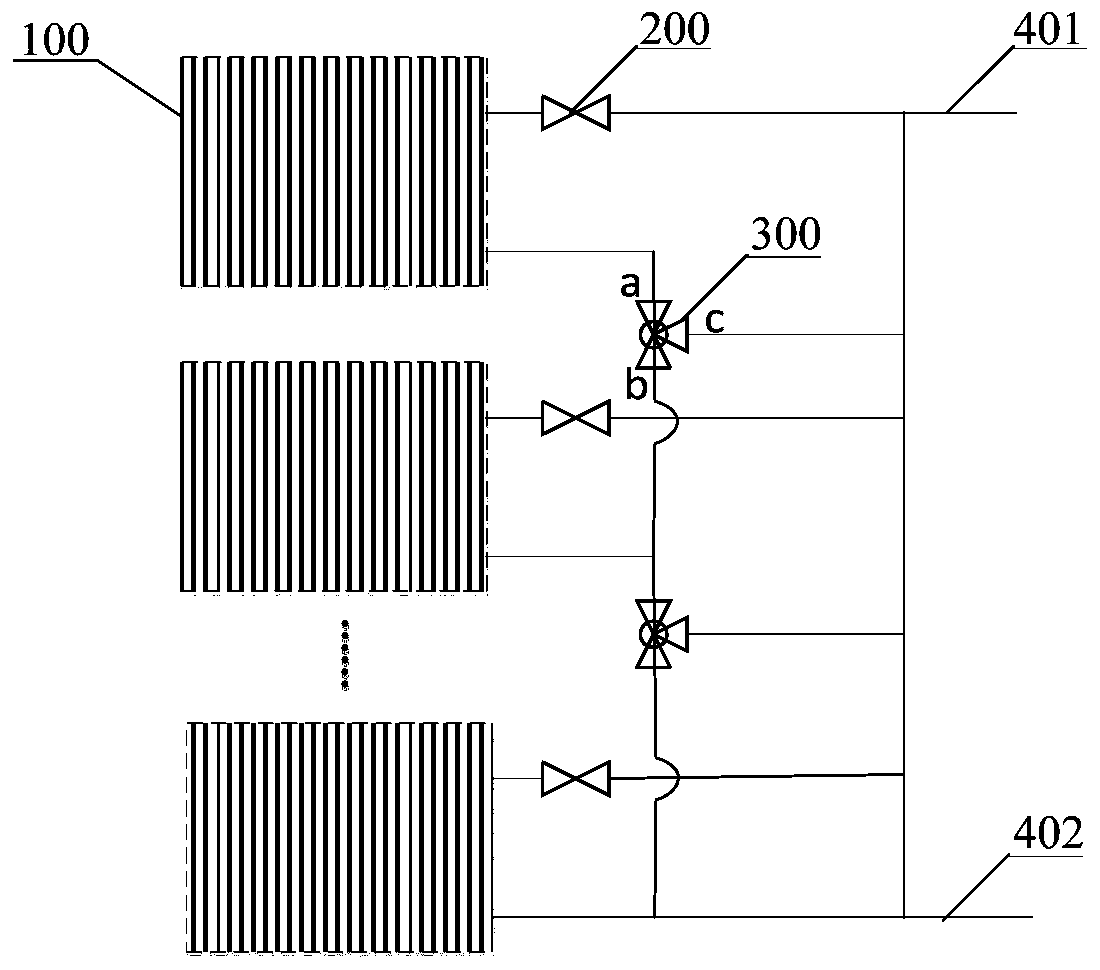

[0030] Such as figure 1 As shown, the present invention includes phase change heat storage main body 1, heat storage circuit, output circuit and PLC controller four parts, PLC controller 6 is connected with temperature sensors 3-1, 3-2, 3-3, 3- 4. The flow sensors 11-1, 11-2 and the pressure sensor 12 monitor the temperature and pressure changes, and control the flow rate and pipeline switching. Among them, single or multiple heat storage units 100 are used inside the phase change heat storage body 1, which can be regulated by series and parallel connections and valves; electric heating mode and new energy heating mode are available under the heat storage circuit; the output circuit can directly output and auxiliary electric heating output .

[0031] Two heat storage modes will be introduced in detail below: figure 1 As shown, when new energy sources such as solar energy are used for heating, the first three-way valve 7-1 and the second three-way valve 7-2 are respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com