Coal drying device

A technology of drying device and coal, applied in the directions of drying gas arrangement, drying solid materials, local stirring dryer, etc., can solve problems such as waste of resources, and achieve the effect of reducing waste of resources, strengthening sealing and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

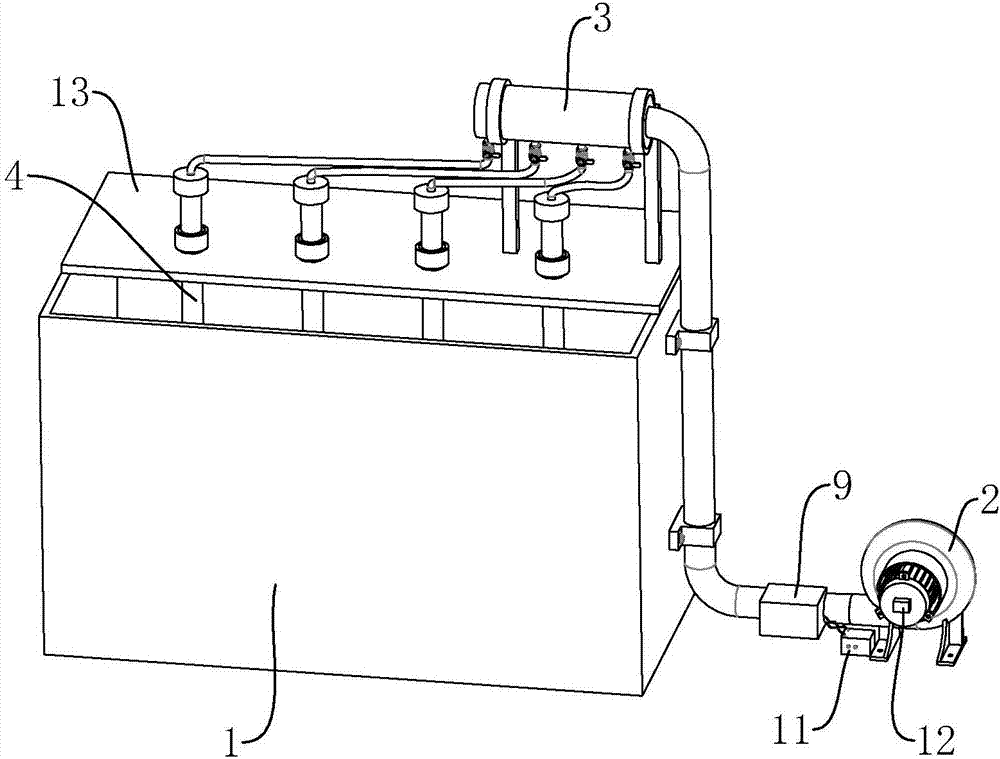

[0039] Embodiment 1: as figure 1 Shown: a coal drying device, including a coal storage box 1, a blower 2, a gas source splitter 3, and a ventilation pipe 4. Ventilation pipe 4 is a stainless steel metal pipe. Coal storage box 1 is used for storing coal. By inserting the ventilation pipe 4 into different coal storage boxes 1, the drying of different coals can be completed, thereby reducing the waste of resources.

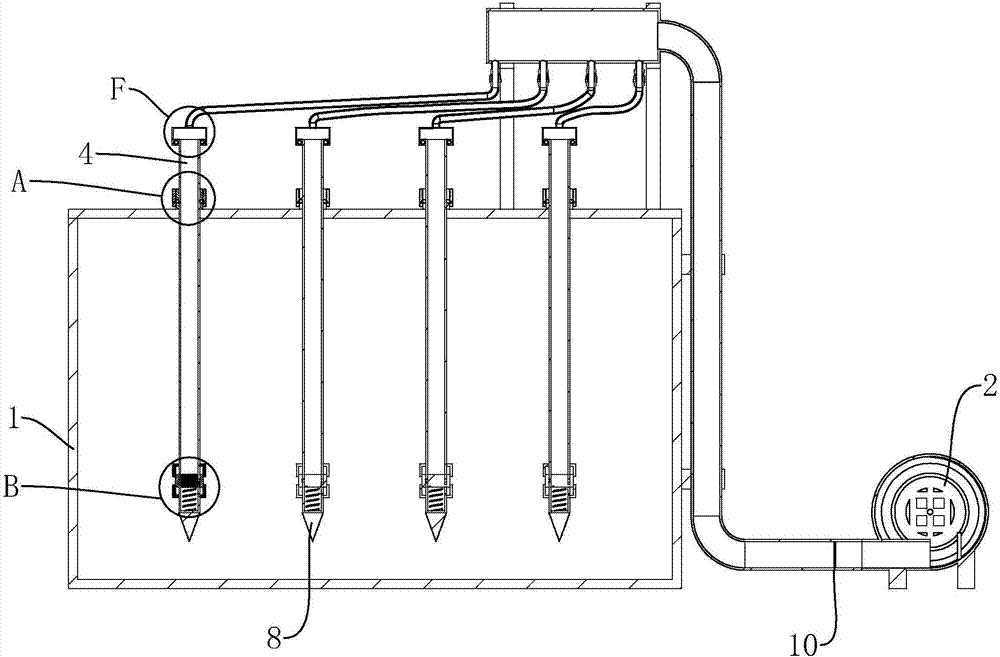

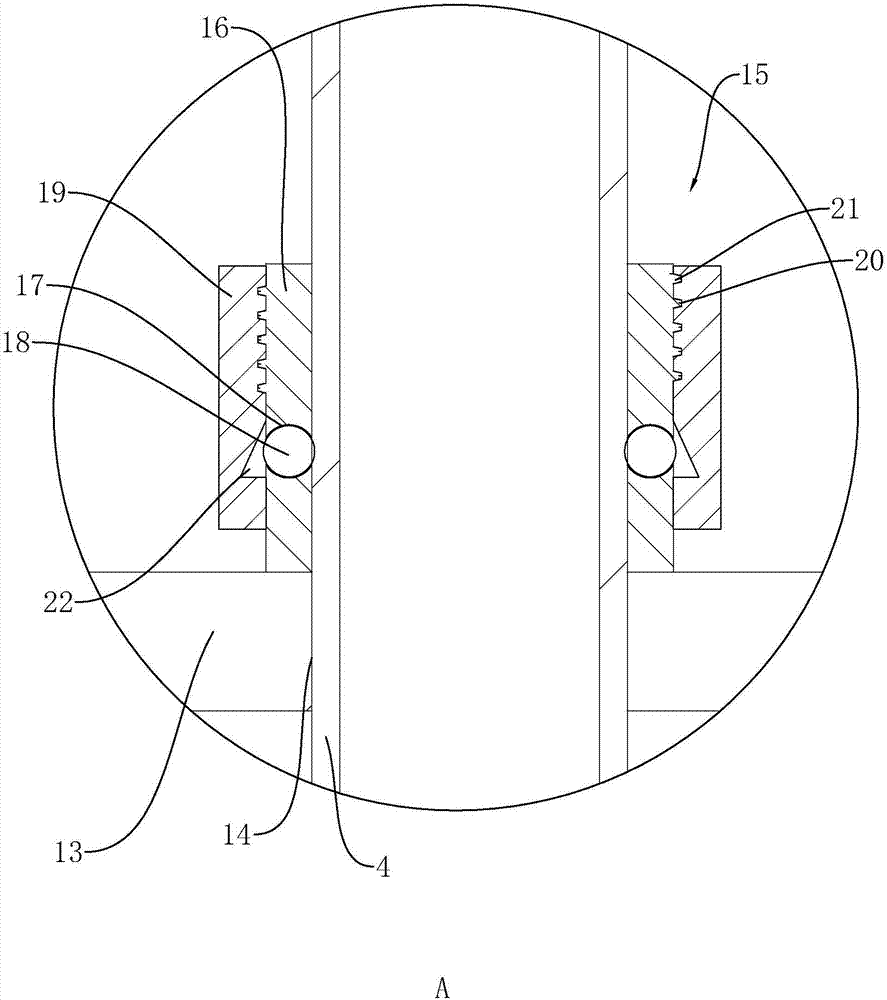

[0040] Such as figure 2 with 9 As shown: the ventilation pipe 4 is provided with a number of air outlets 5 at the end far away from the air source splitter 3 (such as Figure 4 shown). The air outlet 5 is opened in the circumferential direction of the side of the ventilation pipe 4 . One end of the ventilation pipe 4 is connected with a buffer pipe 6 through a sealed bearing 7 , and the other end of the ventilation pipe 4 is fixed with a drill bit 8 . The buffer pipe 6 is connected with the air source splitter 3 . By rotating the ventilation pipe 4, it is co...

Embodiment 2

[0049] Embodiment 2: Embodiment 2 differs from Embodiment 1 only in that the air outlet 5 and the opening and closing assembly 23 are different.

[0050] Such as Figure 5 As shown: the air outlet 5 is arranged on the side wall of the ventilation pipe 4 and there are a plurality of them in the vertical direction.

[0051] Such as Figure 7 As shown: the opening and closing assembly 23 includes: the opening and closing ring 32 that is arranged in the ventilation pipe 4 and is used to open and close the air outlet 5 is rotated. When the control port 33 corresponds to the air outlet 5, the air outlet 5 is opened, and when the control port 33 is not corresponding to the air outlet 5, the air outlet 5 is closed. The wind is blown out from the opening and closing ring 32 through the control port 33 and the air outlet 5 .

[0052] Such as Figure 8 As shown: the ventilation pipe 4 is provided with a rotation groove 34, and a handle 35 fixedly connected with the opening and closin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com