Furnace tube turbulent flow structure and heating furnace with same

A furnace tube and spoiler technology, applied in the furnace tube spoiler structure and the heating furnace with it, can solve the problems of poor heat exchange effect, slow air flow, no flow, etc., to prolong the service life and eliminate stagnation Area, improve the effect of heat exchange energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

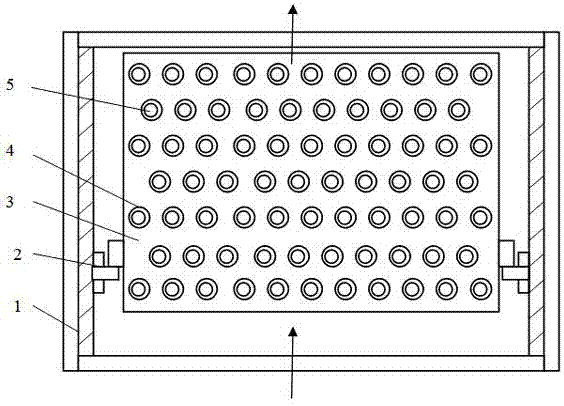

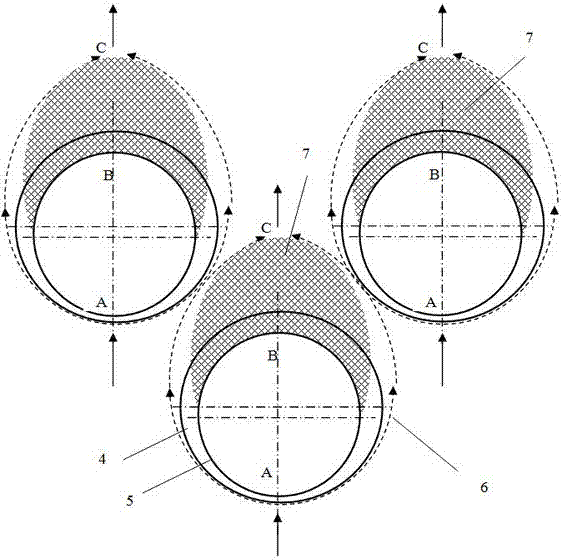

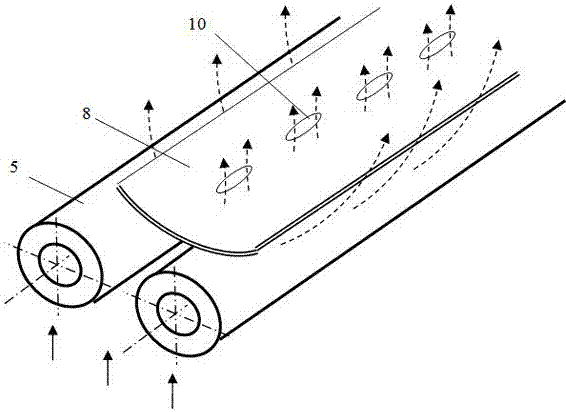

[0039] One of the specific implementations of a furnace tube turbulence structure of the present invention, such as image 3 with Figure 4 As shown, the furnace tube turbulence structure includes a spoiler 8, and the spoiler 8 is installed between two adjacent furnace tubes 5 through the legs 9, and the adjacent two furnace tubes 5 are preferably arranged in parallel, and the legs 9 and The furnace tube 5 can be cast or processed in one piece, or the legs can be assembled and welded to the outer wall of the furnace tube 5 one by one. Since each furnace tube 5 is generally installed in the corresponding tube plate hole 4, the spoiler 8 is actually installed between two adjacent tube plate holes 4. 4 is simplified or directly omitted without being shown. For the convenience of describing the core technology, the description of the tube plate hole 4 is directly omitted in this embodiment. The spoiler 8 is located on the back side of the furnace tube 5 facing away from the flow...

Embodiment 2

[0044] The second specific embodiment of a kind of furnace tube turbulence structure of the present invention, such as Figure 5 As shown, the main technical solution of this embodiment is the same as that of Embodiment 1, and the technical features not described in this embodiment are explained using Embodiment 1, and will not be repeated here. The difference between this embodiment and the embodiment is that The spoiler 8 on the furnace tube 5 can be spliced end to end by multi-section spoiler 8 along the length direction of the furnace tube 5. There is a gap at the splicing part. Of course, the splicing part can also be lapped together without spot welding, which can meet the requirements of the spoiler. 8 and the need for coordination of thermal expansion and cold contraction displacement between the furnace tube, and it is also convenient for manufacturing.

[0045] The longitudinal section of the spoiler 8 taken along its length direction is corrugated, and the corruga...

Embodiment 3

[0047] The third specific embodiment of a furnace tube turbulence structure of the present invention, as Image 6 As shown, the main technical solution of this embodiment is the same as that of Embodiment 1, and the technical features not described in this embodiment are explained using Embodiment 1, and will not be repeated here. The difference between this embodiment and the embodiment is that The spoiler 8 is a spiral cylinder formed by spiraling long strips. Specifically, the long strips may be steel wires or thin steel strips. The gas flow at the side of the furnace tube 5 flows through the back of the furnace tube 5 after being deflected and diverted by the spoiler 8, thereby eliminating most of the stagnation area on the back of the furnace tube 5 in the prior art, so that the surrounding area of the furnace tube A 360-degree uniform flow state is formed around, which can ultimately significantly improve the heat exchange efficiency of the furnace tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com