Inner sleeve plate structure for plate-type fractionating tower

A technology of fractionation towers and sets of plates, applied in the direction of fractionation, etc., can solve problems such as non-elimination, achieve the effects of preventing coking, improving mass transfer efficiency, and reducing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

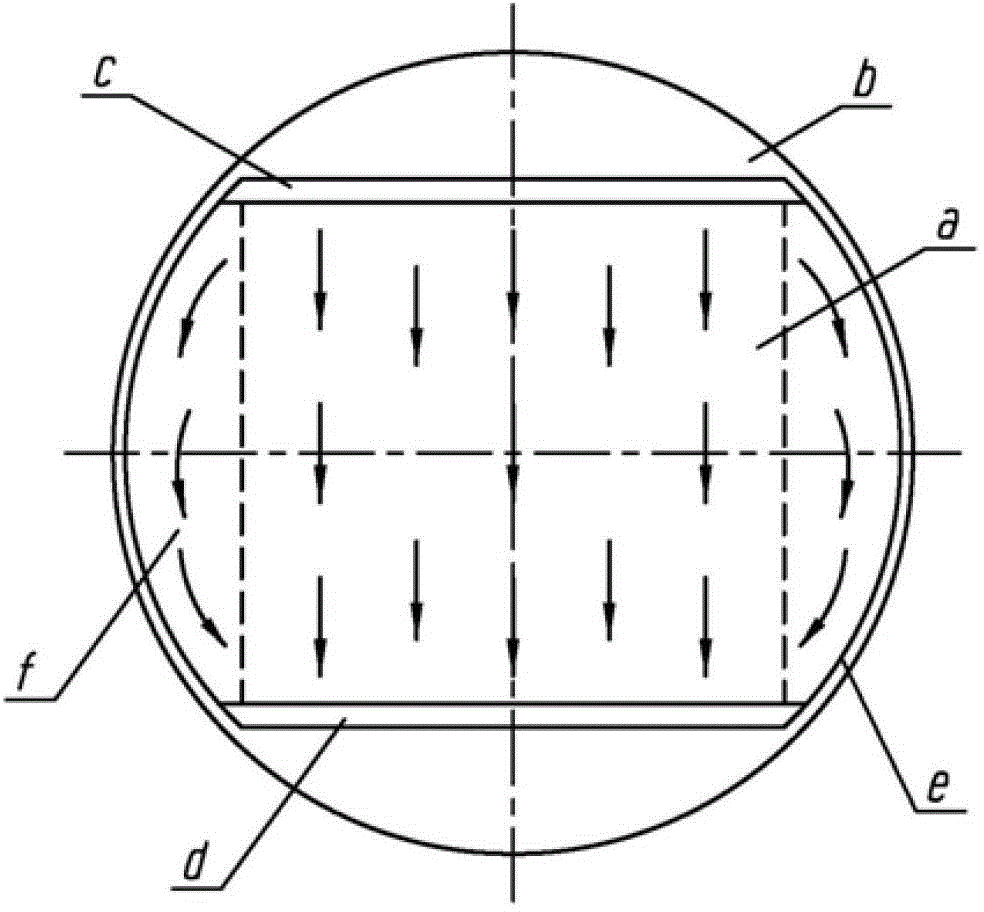

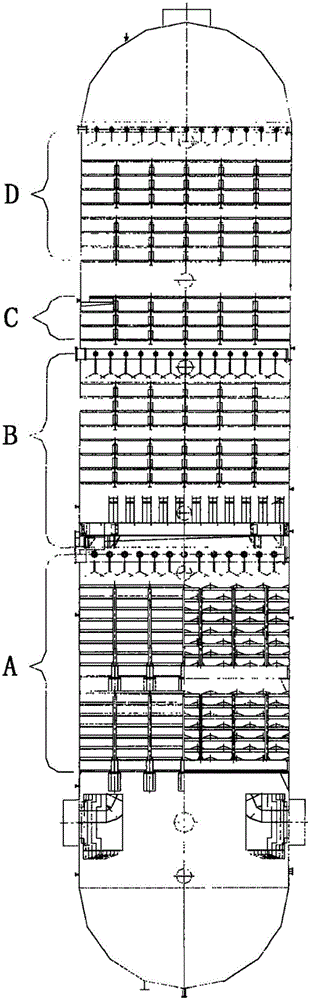

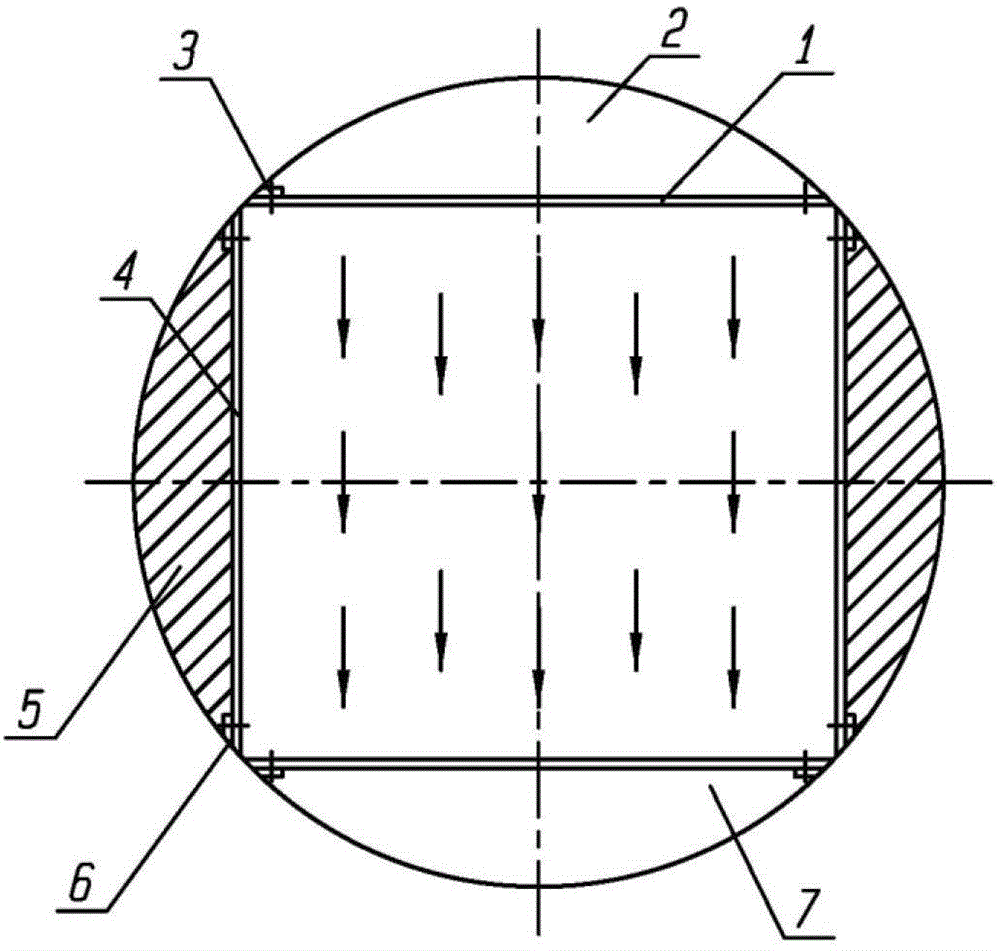

[0039] as attached Figure 4 As shown, according to the vapor-liquid load and the nature of the system in the fractionation tower, the 1# to 3# layer trays need to be installed with inner sleeves to eliminate the stagnation zone. The inner sleeve plate 4 of the plate type fractionation column of the present invention is arranged to cover the 1#~3# layer trays. The top of the inner casing plate is not lower than the liquid layer height on the 3# tray plate, and the bottom edge is lower than the 1# tray plate; the top of the inner casing plate is blocked by the top cover plate 5, and the lower part is open.

[0040] attached Figure 4 , Figure 5 In the application example, the inner sleeve plate 4 is composed of three inner sleeve plate combination plates 4-1, 4-2, 4-3, and the three inner sleeve plate combination plates are connected by bolts; the inner sleeve plate 4 and The top cover plate 5, the top cover plate 5 and the top cover plate supporting plate 8 are connected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com