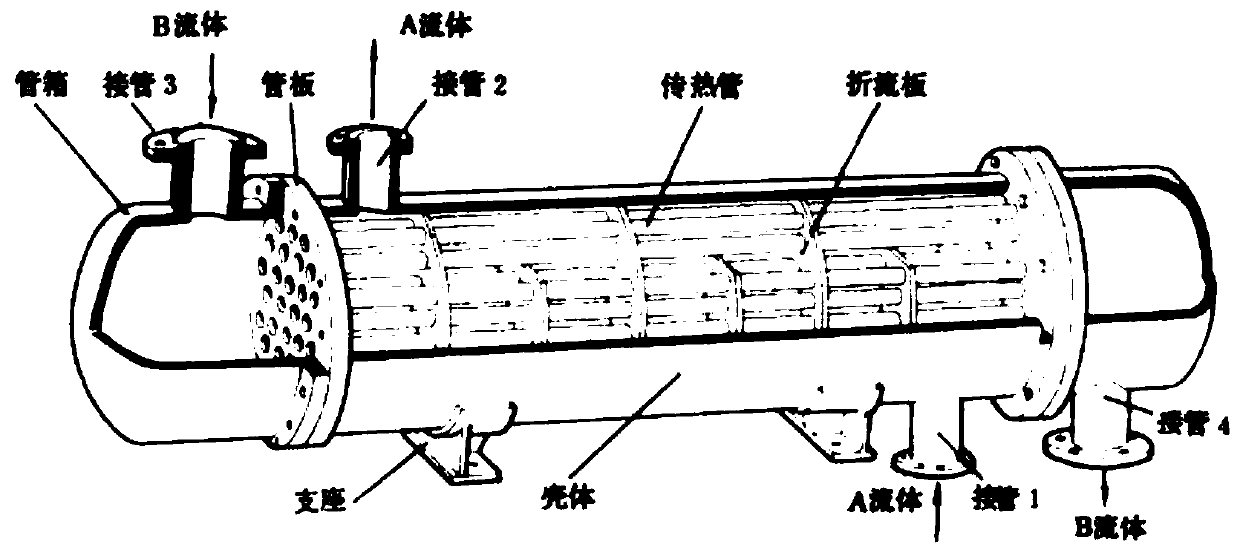

Baffle assemblies and shell and tube heat exchangers incorporating same

A technology of baffles and components, which is applied in the field of enhanced heat transfer of heat exchangers, and can solve problems such as heat transfer efficiency in stagnant flow areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

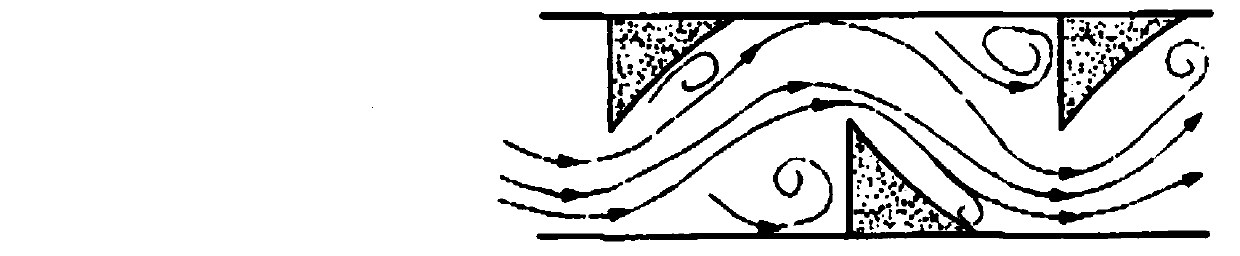

Problems solved by technology

Method used

Image

Examples

Embodiment 1

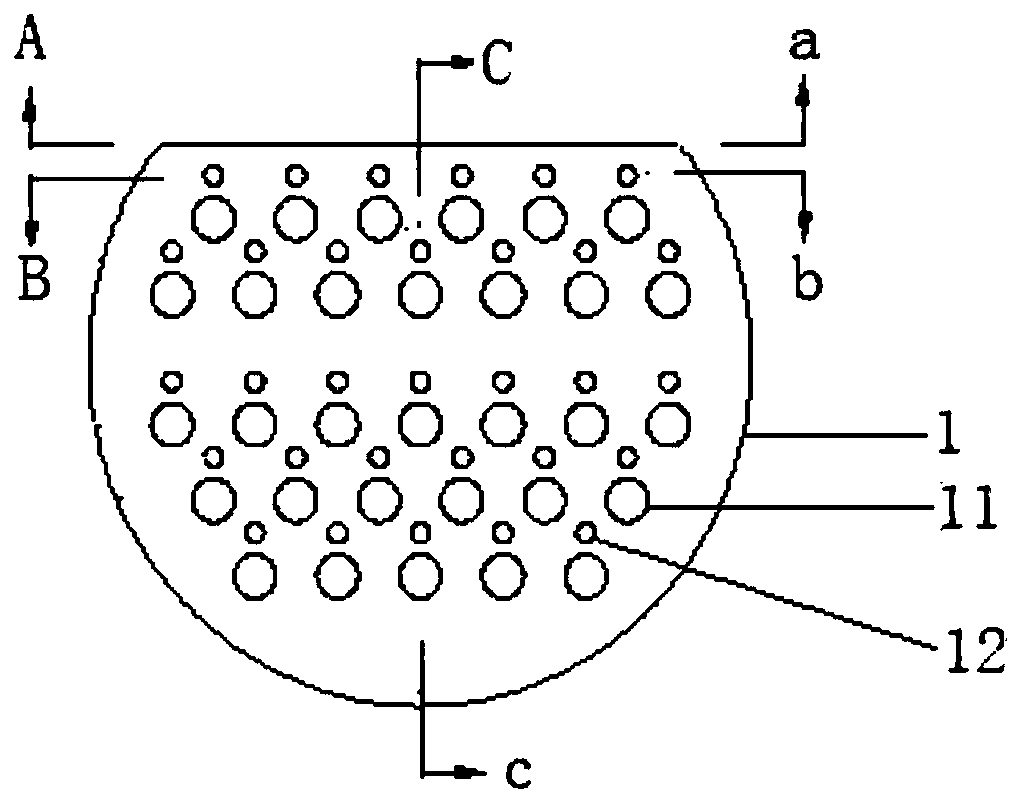

[0043] Such as image 3 As shown, a baffle assembly includes a baffle 1, and a plurality of heat transfer tube installation holes 11 are arranged in the baffle 1 for installing the heat transfer tube 2, and the feature is that: the baffle 1 is also provided with There are a plurality of jet tube installation holes 12, the jet tube 3 penetrates and is fixed in the jet tube installation hole 12, the jet tube installation hole 12 is adjacent to the heat transfer tube installation hole 11, the jet tube 3 is adjacent to the heat transfer tube 2, The jet tube 3 is provided with a jet outlet in a direction relative to the heat transfer tube 2 .

[0044] Such as Figure 5 As shown, the jet tube 3 is composed of an inlet section 31 , an installation section 32 and a jet section 33 , which are sequentially sealed and connected.

[0045] The inlet section 31 has a trumpet-shaped structure, the installation section 32 is socketed and connected with the jet tube installation hole 12, and...

Embodiment 2

[0064] Such as image 3 As shown, a baffle assembly includes a baffle 1, and a plurality of heat transfer tube installation holes 11 are arranged in the baffle 1 for installing the heat transfer tube 2, and the feature is that: the baffle 1 is also provided with There are a plurality of jet tube installation holes 12, the jet tube 3 penetrates and is fixed in the jet tube installation hole 12, the jet tube installation hole 12 is adjacent to the heat transfer tube installation hole 11, the jet tube 3 is adjacent to the heat transfer tube 2, The jet tube 3 is provided with a jet outlet in a direction relative to the heat transfer tube 2 .

[0065] Such as Figure 5 As shown, the jet tube 3 is composed of an inlet section 31 , an installation section 32 and a jet section 33 , which are sequentially sealed and connected.

[0066] The inlet section 31 has a trumpet-shaped structure, the installation section 32 is socketed and connected with the jet tube installation hole 12, and...

Embodiment 3

[0080] Such as Figure 4 As shown, a baffle assembly includes a baffle 1, and a plurality of heat transfer tube installation holes 11 are arranged in the baffle 1 for installing the heat transfer tube 2, and the feature is that: the baffle 1 is also provided with There are a plurality of jet tube installation holes 12, the jet tube 3 penetrates and is fixed in the jet tube installation hole 12, the jet tube installation hole 12 is adjacent to the heat transfer tube installation hole 11, the jet tube 3 is adjacent to the heat transfer tube 2, The jet tube 3 is provided with a jet outlet in a direction relative to the heat transfer tube 2 .

[0081] Such as Figure 5 As shown, the jet tube 3 is composed of an inlet section 31 , an installation section 32 and a jet section 33 , which are sequentially sealed and connected.

[0082] The inlet section 31 has a trumpet-shaped structure, the installation section 32 is socketed and connected with the jet tube installation hole 12, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com