Studded tube with uniform flow cover and heating furnace with studded tube

A nail head and flow cover technology is applied in the field of heating furnace, which can solve the problems of poor heat exchange effect, slow airflow, affecting the heat exchange effect of nail head tube, etc., and achieve the effect of improving heat exchange energy efficiency and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

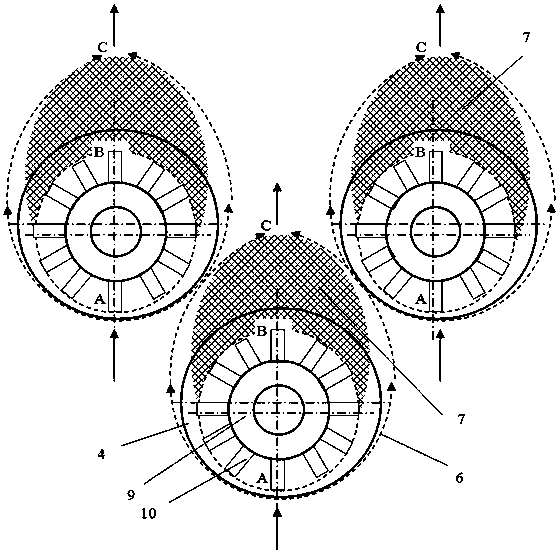

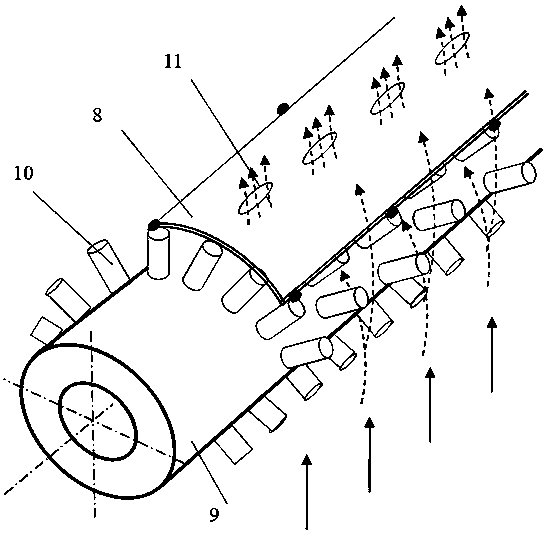

[0039] One of the specific implementations of a nail head tube with a uniform flow cover of the present invention, such as image 3 and Figure 4 As shown, the nail head tube includes a base pipe 9 and a nail head 10 installed on the outer wall of the base pipe 9 for accelerating heat exchange. Group welded to the outer wall of the base pipe 9. The nail head 10 located on the back side of the base pipe 9 facing away from the flow direction of the air flow is provided with a uniform flow cover 8, the cross section of the nail head 10 is circular, oblong or rectangular, and the root of the nail head 10 is affixed to the base pipe 9, The end of the nail head 10 is welded and fixed with the uniform flow cover 8, specifically, as image 3 The middle uniform flow cover 8 can be close to the nail head tube on the whole bottom surface, and the two sides of the uniform flow cover 8 are fixedly connected with the nail head 10 by spot welding respectively. Of course, it can also be fix...

Embodiment 2

[0044] The second specific embodiment of a nailhead tube with a uniform flow cover of the present invention, as Figure 5 As shown, the main technical solution of this embodiment is the same as that of Embodiment 1, and the technical features not described in this embodiment are explained using Embodiment 1, and will not be repeated here. The difference between this embodiment and the embodiment is that The uniform flow cover 8 on the nail head 10 can be formed by splicing the multi-section uniform flow cover 8 end to end along the length direction of the base pipe 9. There is a gap at the splicing part. Of course, the splicing parts can also be overlapped together without spot welding, which can meet the requirements of the uniform flow cover. The need for thermal expansion and cold contraction coordination between the 8 and the nail head tube is also convenient for manufacturing.

[0045] In this embodiment, the uniform flow cover 8 and the nail head pipe are assembled toget...

Embodiment 3

[0047] The third specific embodiment of a nailhead tube with a uniform flow cover of the present invention, as Figure 6 As shown, the main technical solution of this embodiment is the same as that of Embodiment 1, and the technical features not described in this embodiment are explained using Embodiment 1, and will not be repeated here. The difference between this embodiment and the embodiment is that The uniform flow cover 8 and the nail head tube are clamped on the nail head tube by using elastic pins 13, which simplifies the assembly process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com