Machining tool with error correction function

A processing machine tool and error correction technology, applied in metal processing mechanical parts, metal processing equipment, manufacturing tools, etc., can solve the problems that affect the effective processing and production of precision parts, increase the production cost of enterprises, and the inability of precision parts to achieve accurate error compensation , The effect of improving the production qualification rate and restoring the operation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

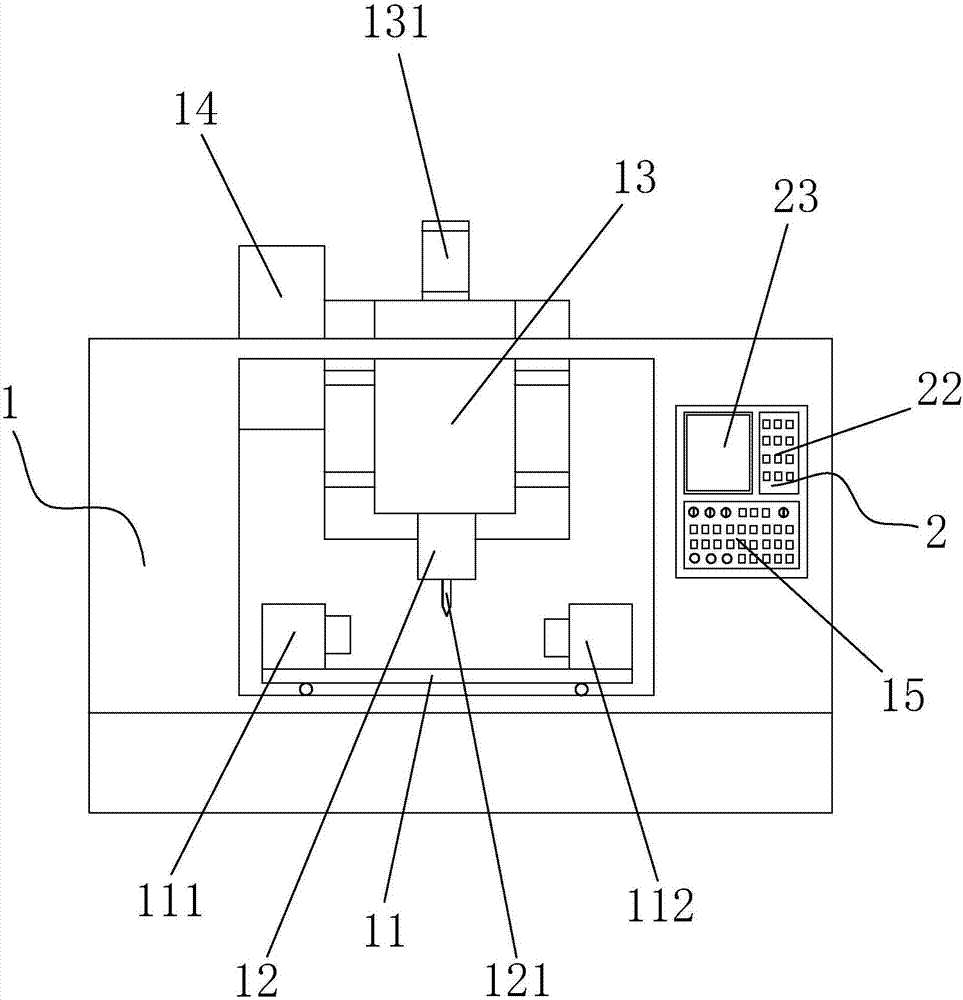

[0012] Reference figure 1 , A processing machine tool with error correction function of the present invention includes a processing machine tool 1 for processing precision parts and a correction device 2 for correcting the accuracy of the processing machine tool 1. The processing machine tool 1 includes a precision The worktable 11 for the parts, the processing spindle 12 for processing precision parts, and the processing cylinder 131 for driving the processing spindle 12 to move up and down. The end of the processing spindle 12 is provided with a drill 121 for processing precision parts. The main shaft 12 and the drill 121 are both set above the worktable 11; the correction device 2 includes a PLC module used to compensate the stroke data of the machining main shaft 12, a digital key panel 22 used to input compensation data, and a digital key panel 22 used to display operating data, The display screen 23 for compensation data and operating status, the digital key panel 22, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com