Hybrid algorithm for measuring manufacturing process multivariate quality capacity

A technology of manufacturing process and process quality, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of unsuitable multi-quality characteristics production process, not considering multi-quality characteristics, etc., to achieve accurate state results and algorithm adaptation. Strong, conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

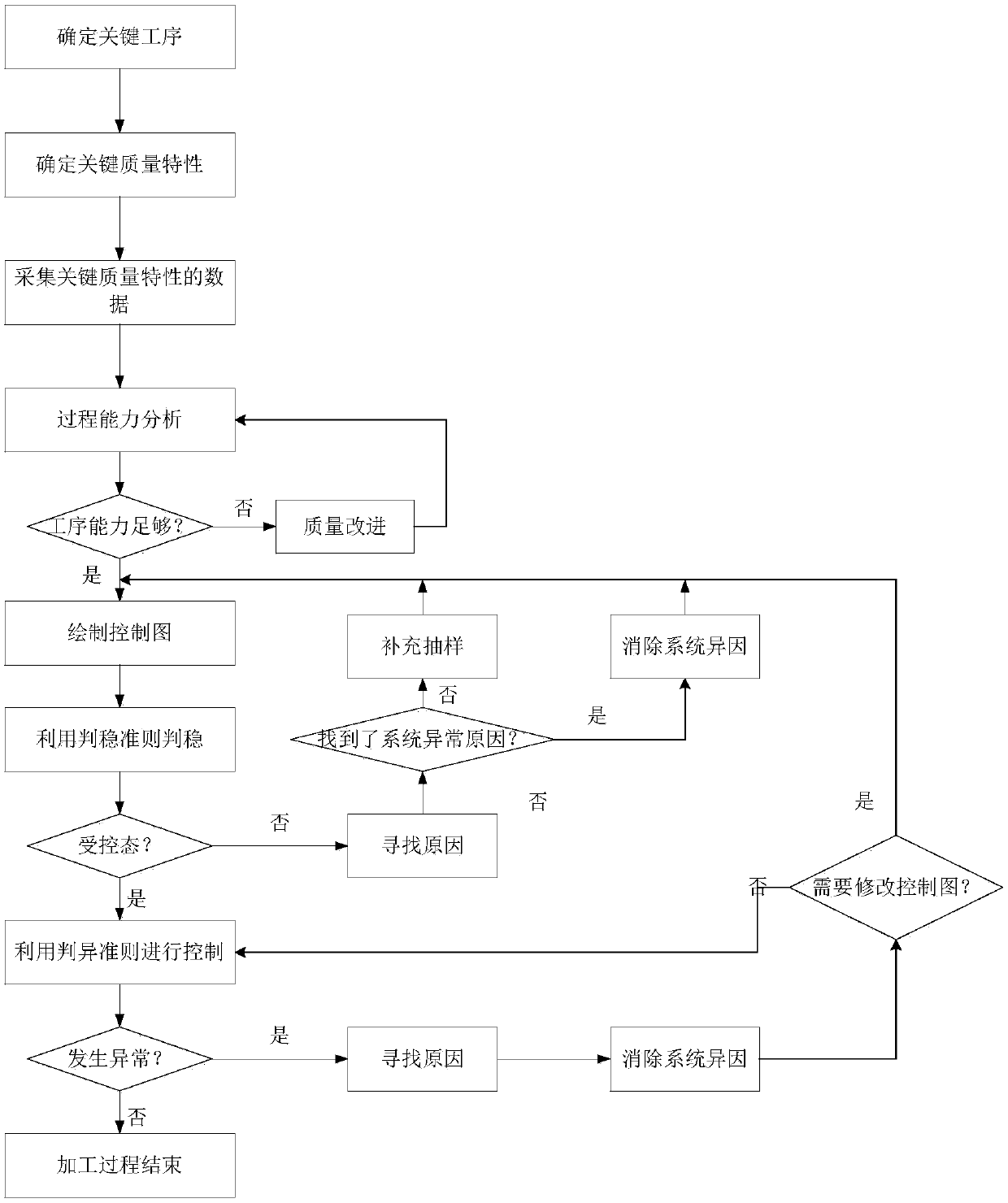

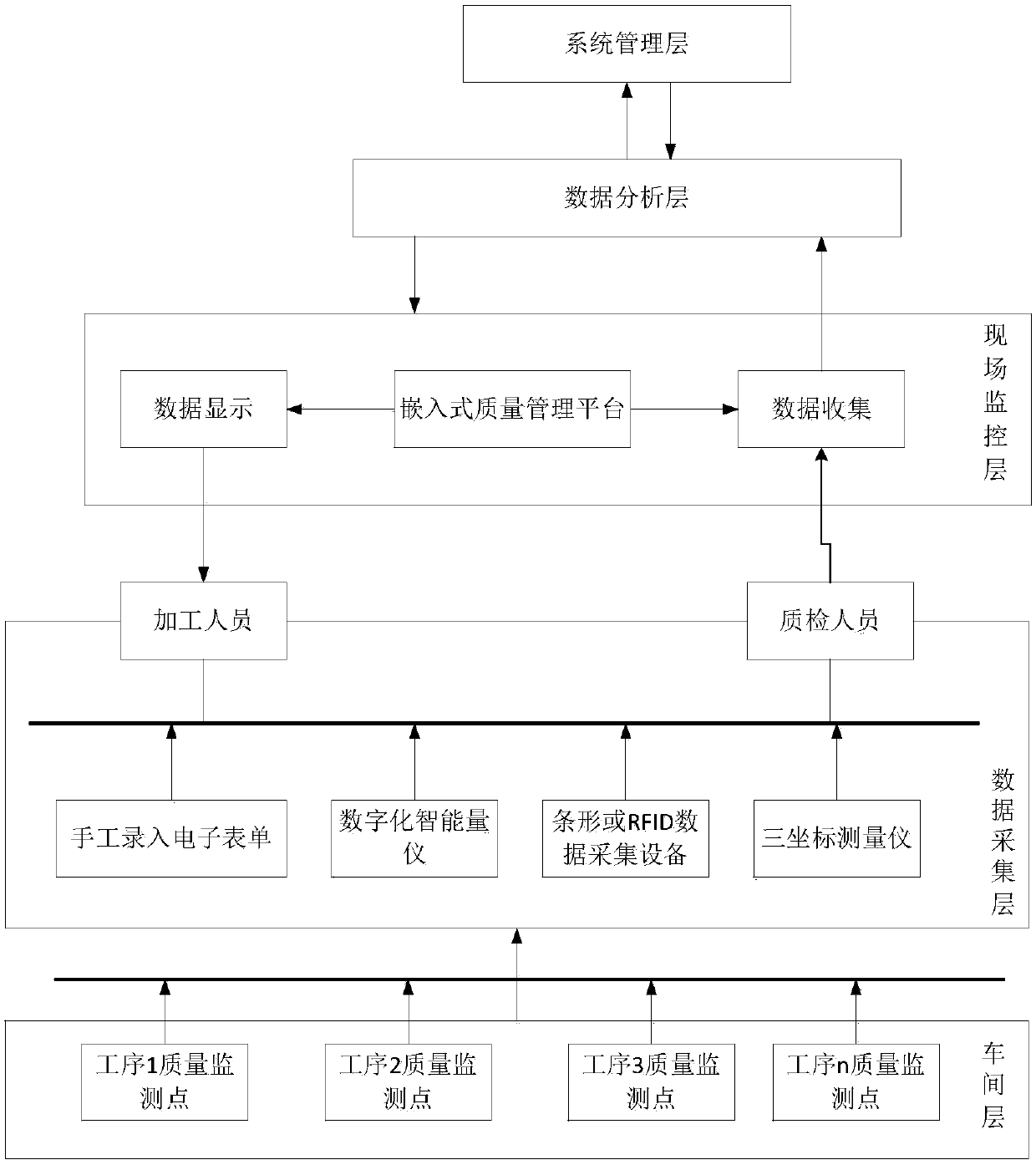

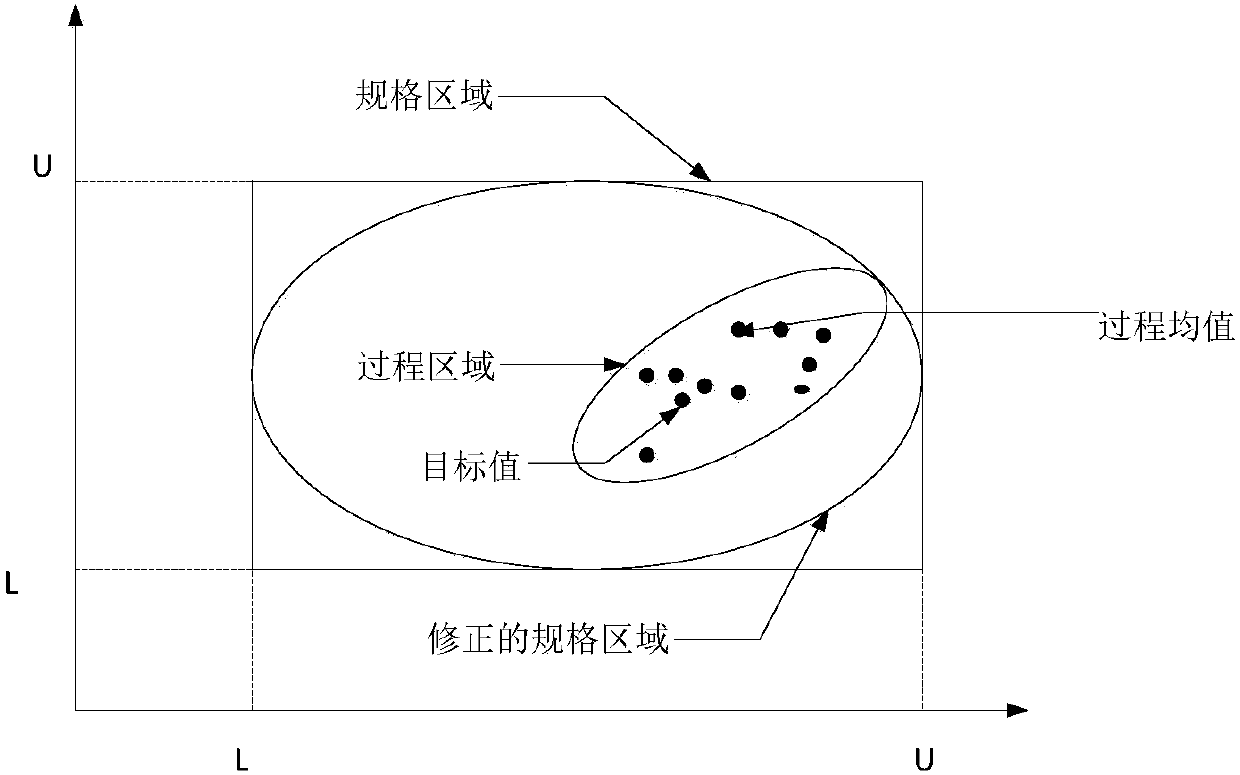

[0021] In order to solve the problems existing in the quality control of traditional workshops, combined with Figure 1-Figure 3 The present invention has been described in detail, and its specific implementation steps are as follows:

[0022] Step 1: Collect the raw data of quality characteristics in the manufacturing process, and perform necessary collation, simplification and calculation on the data.

[0023] Step 2: Carry out process analysis on the multivariate quality characteristics of key processes, and the specific calculation process is as follows:

[0024] In the production process, when there is no systematic error in the process, the quality characteristic value X of the product conforms to the normal distribution, X∈N(μ,σ 2 ), where X is the quality property value, μ is the overall mean, and σ 2 is the overall variance. When the quality characteristic value obeys the normal distribution, its mean Also obey the normal distribution, where n is the sample size....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com