Patents

Literature

54results about How to "Avoid inaccurate results" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

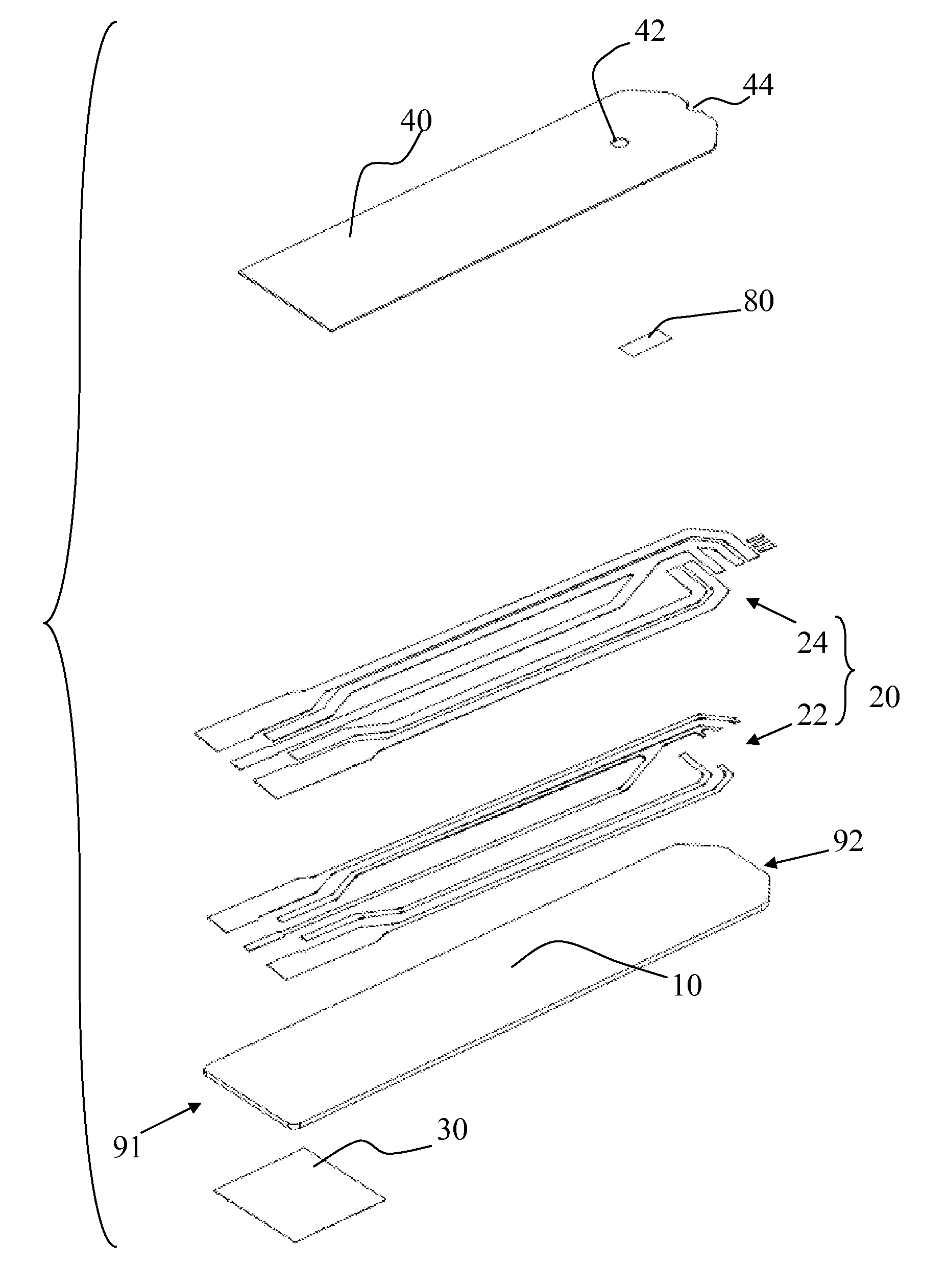

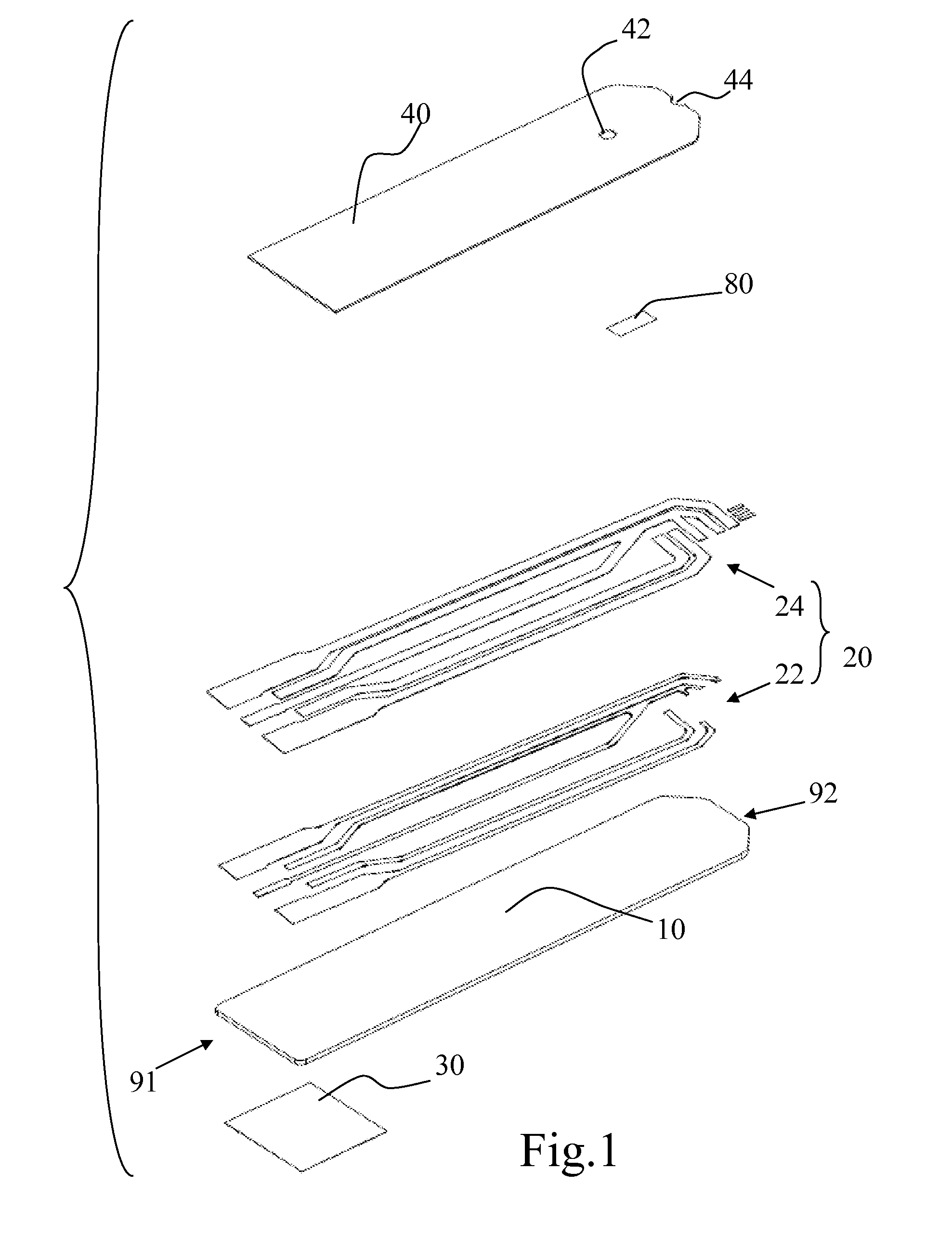

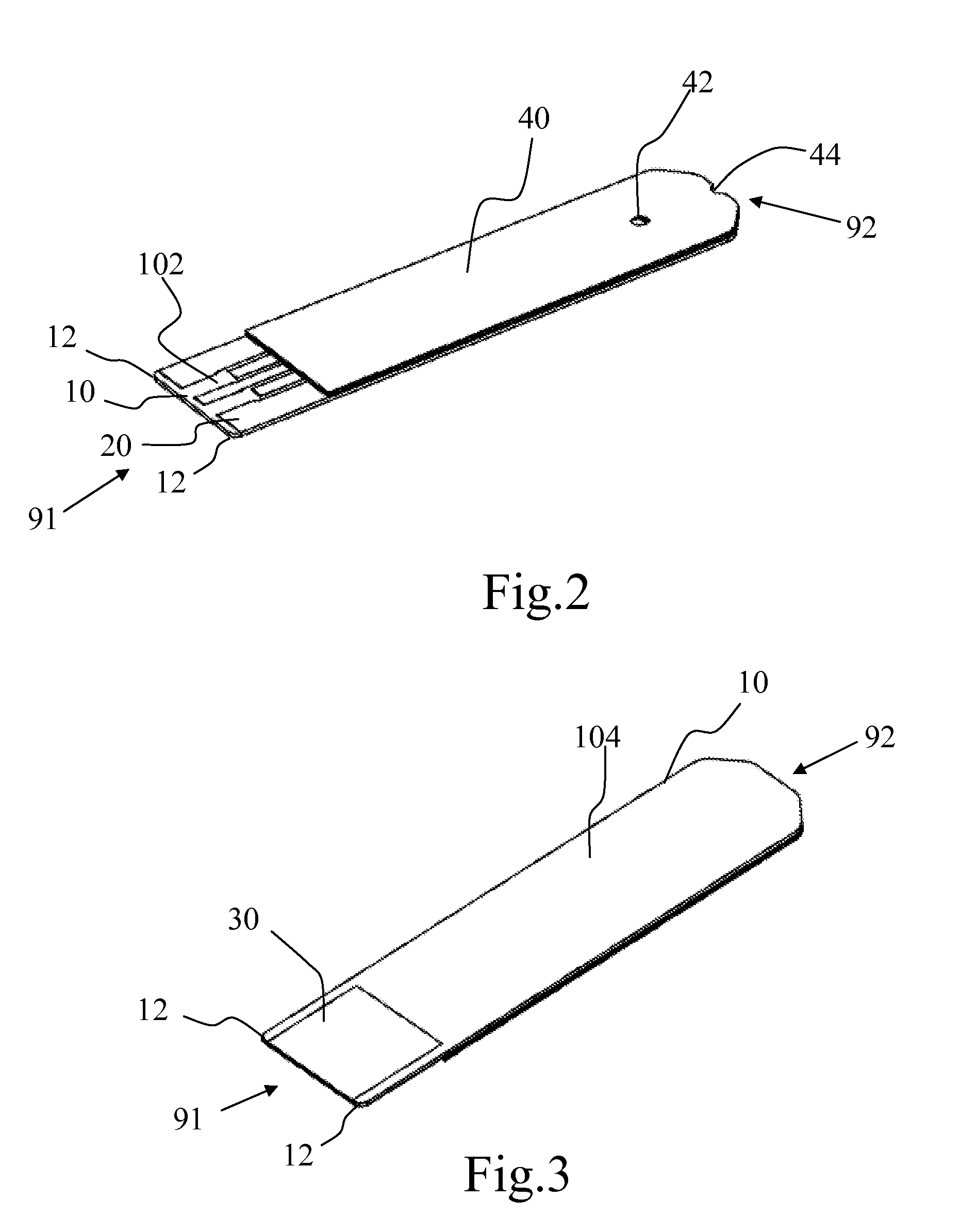

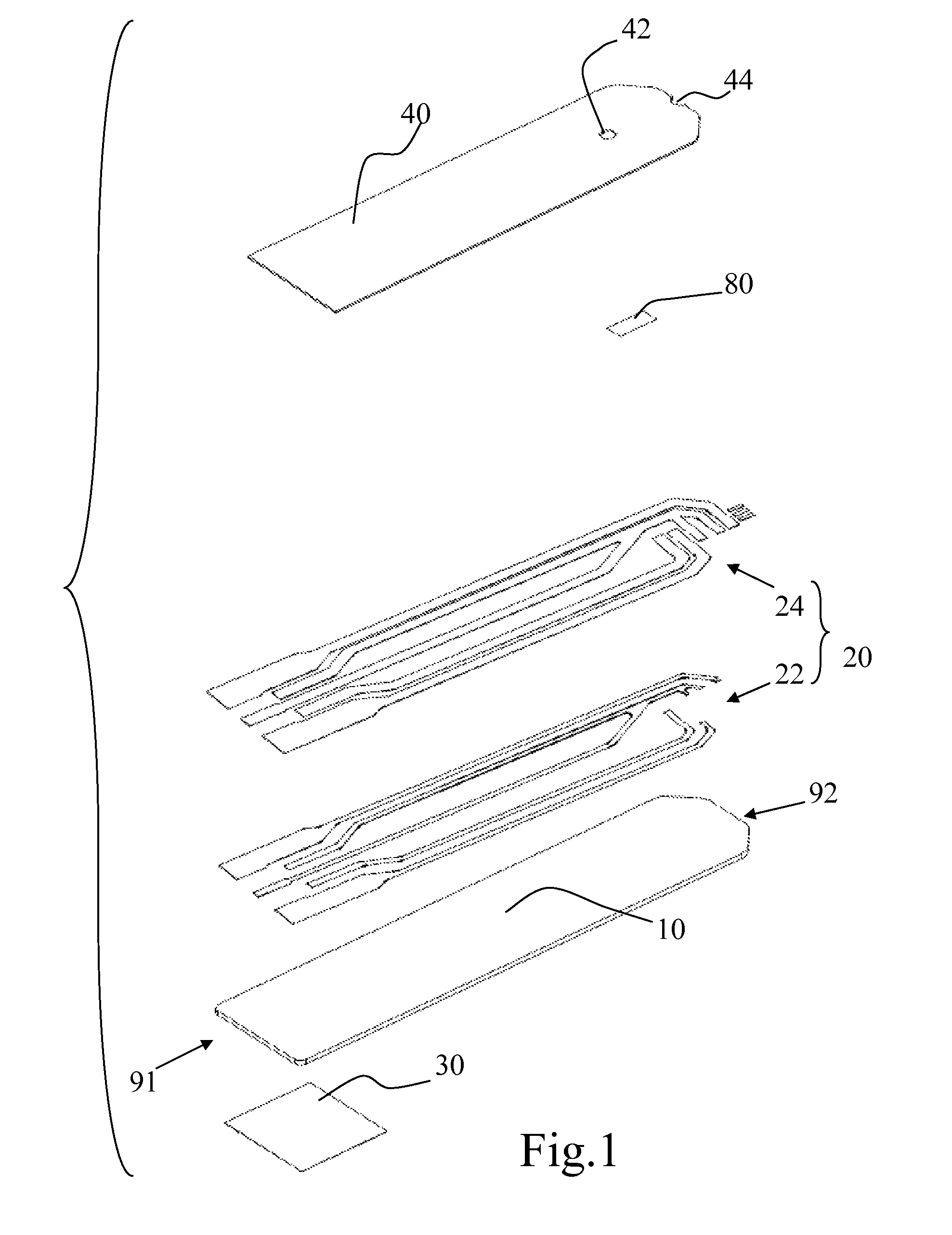

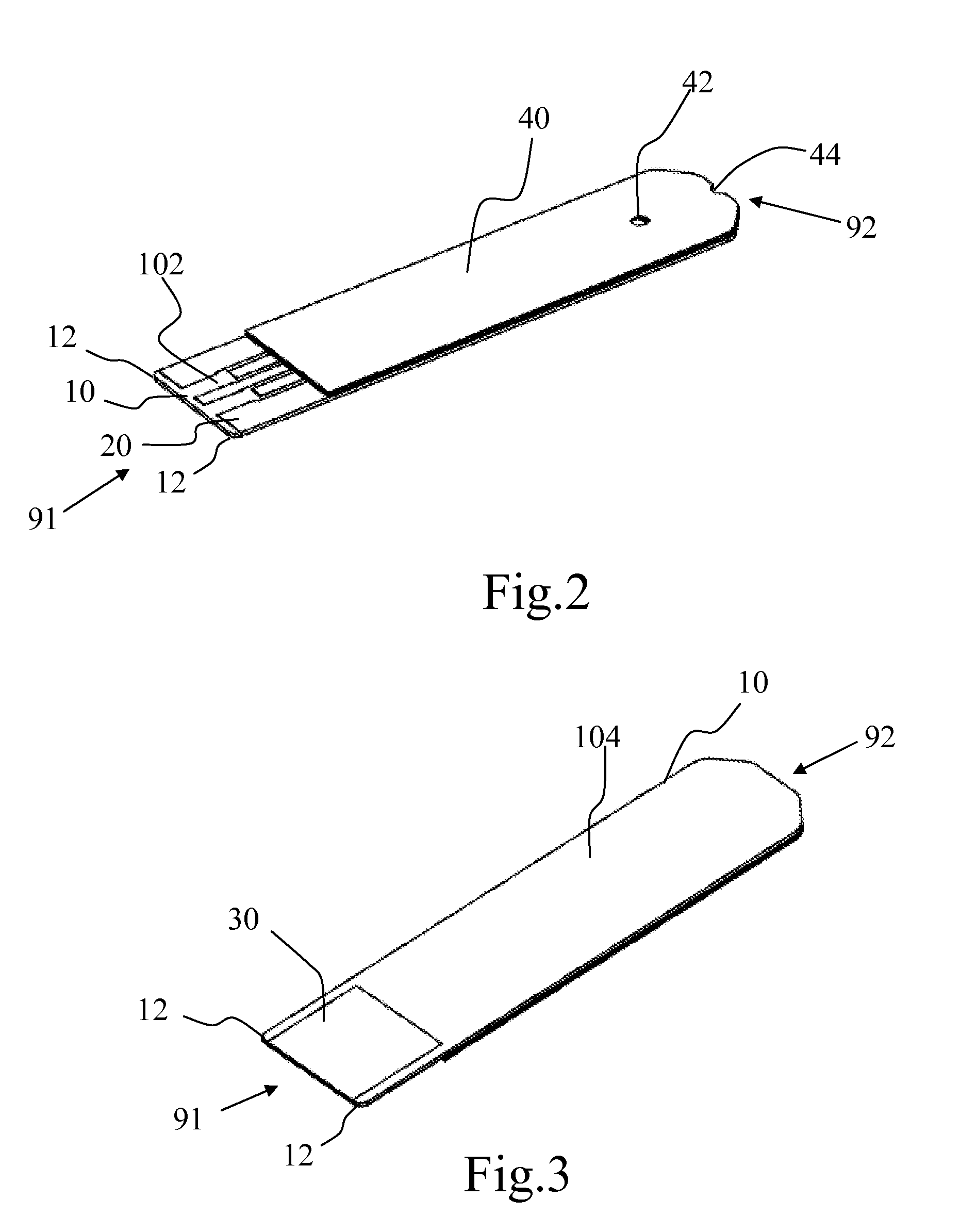

Electrochemical biosensor strip and method for identifying a corresponding biosensing device by said strip

ActiveUS20110139635A1Eliminates calibration stepSimplify the measurement procedureImmobilised enzymesBioreactor/fermenter combinationsElectrochemical biosensorEngineering

The present invention relates to an electrochemical biosensor strip comprising a base which has a front side and a back side, an electrode system on the front side of said base, a code-recognition element on one end of the back side of said base, a cover which is located on said electrode system, and a reaction area which is in touch with said electrode system for a reaction to take place. By forms of said code-recognition element provided in the present invention, a biosensing device will automatically choose a specific set of calibration code corresponding to a particular batch of the electrochemical biosensor strip while coupling to the strip. Hence, the present invention eliminates the calibration step carried out by users and simplifies the measuring procedure, avoiding the inaccurate results due to the omission or improper operation of the calibration step by users. The present invention further relates to a method for identifying a corresponding biosensing device by using a ratio of lengths of each length-changeable area of the strip.

Owner:TAIDOC TECH CORP

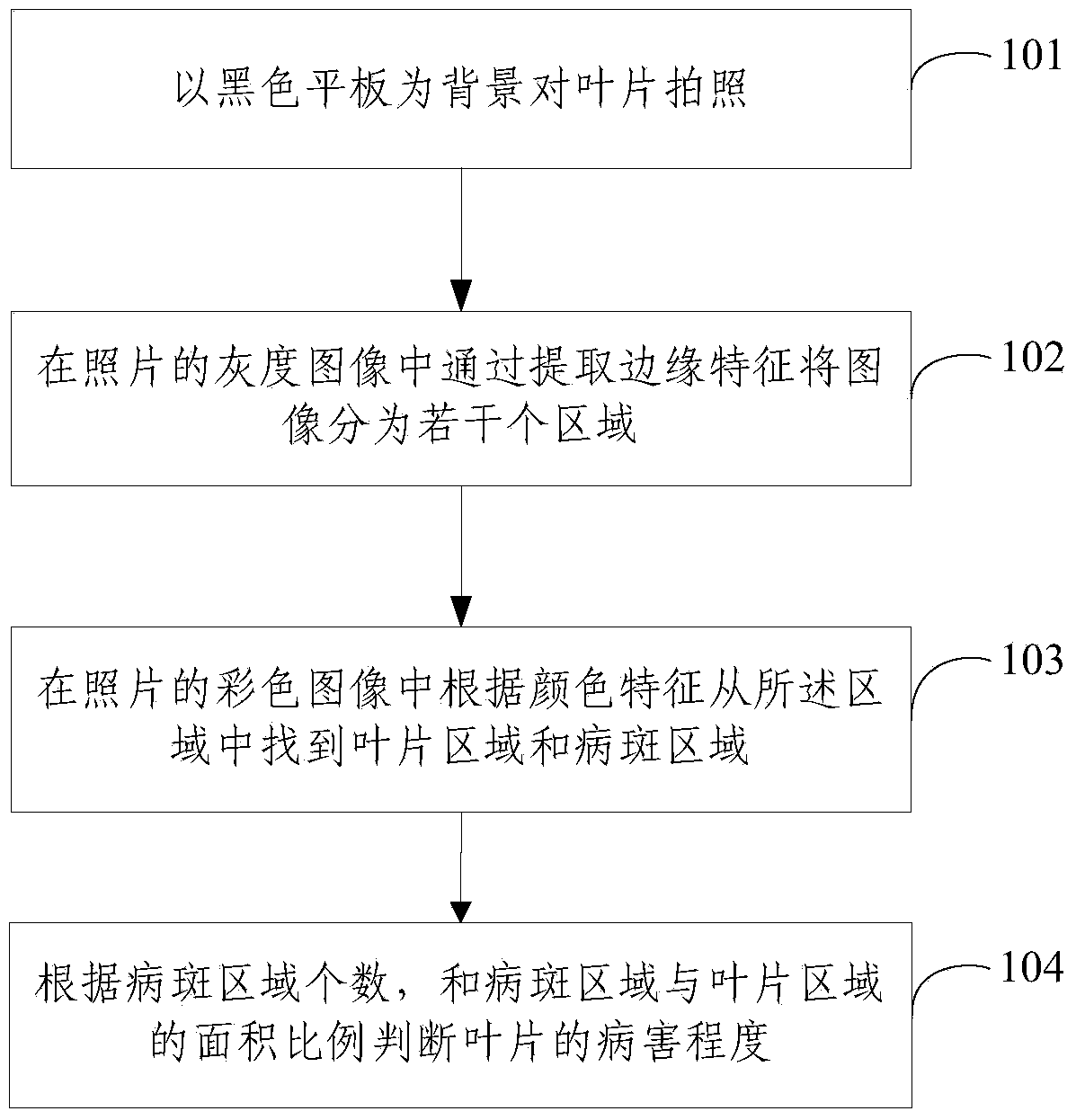

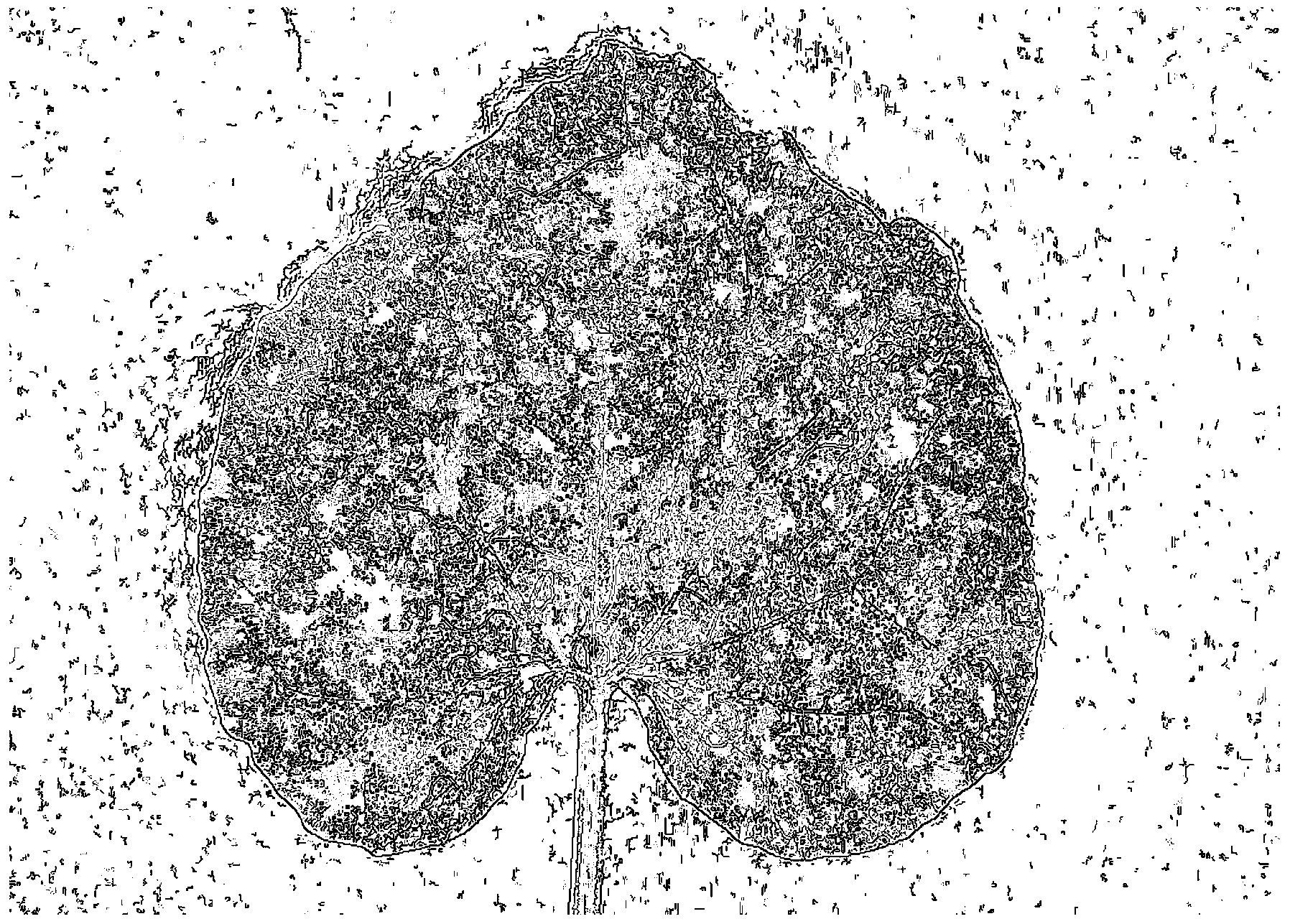

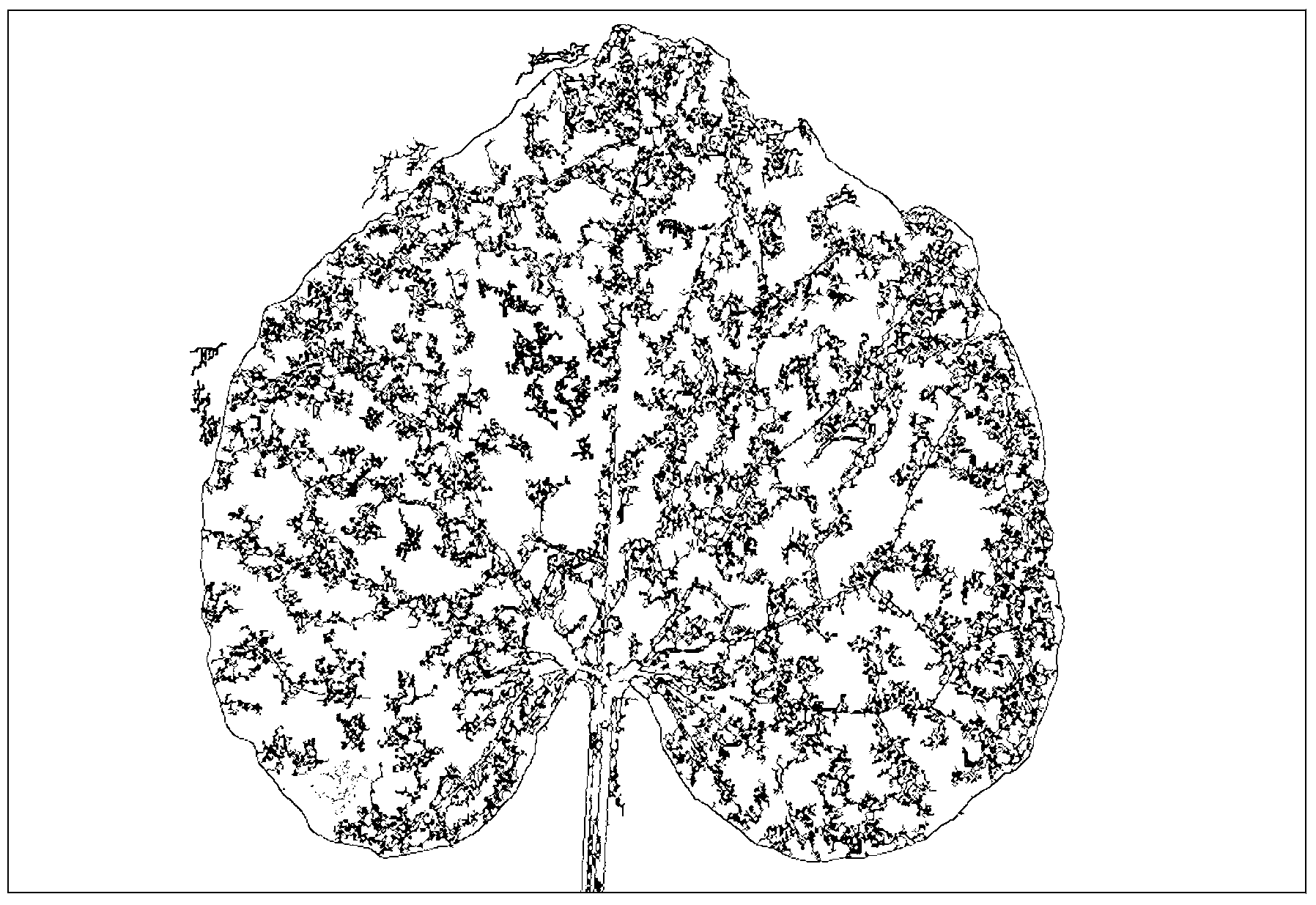

Method and system for acquiring disease severity of leaf under open field environment

ActiveCN103778628AAvoid inaccurate resultsReduce labor intensityImage analysisColor imageAcquired diseases

The invention relates to agricultural engineering and particularly relates to a method and a system for acquiring the disease severity of a leaf under an open field environment. The method comprises the following steps: taking a picture of a leaf against a black flat plate; extracting edge features in a gray image of the picture to divide the image into a plurality of regions; finding out leaf regions and diseased spot regions from the regions according to color features in a color image of the picture; and judging the disease severity of the leaf according to the number of the diseased spot regions and the area ratio of the diseased spot regions to the leaf regions. The disease severity of a leaf can be accurately calculated under an open field environment.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

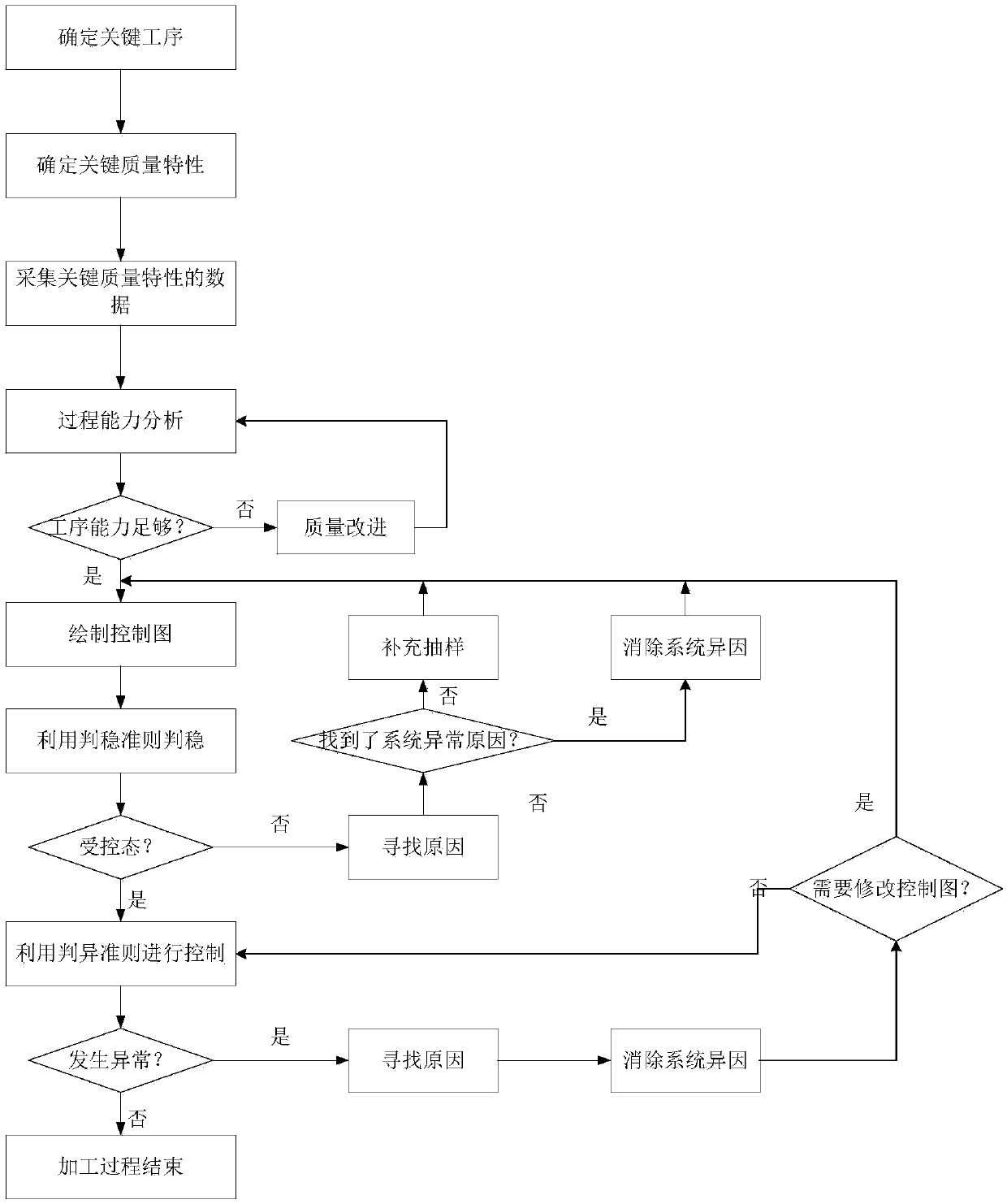

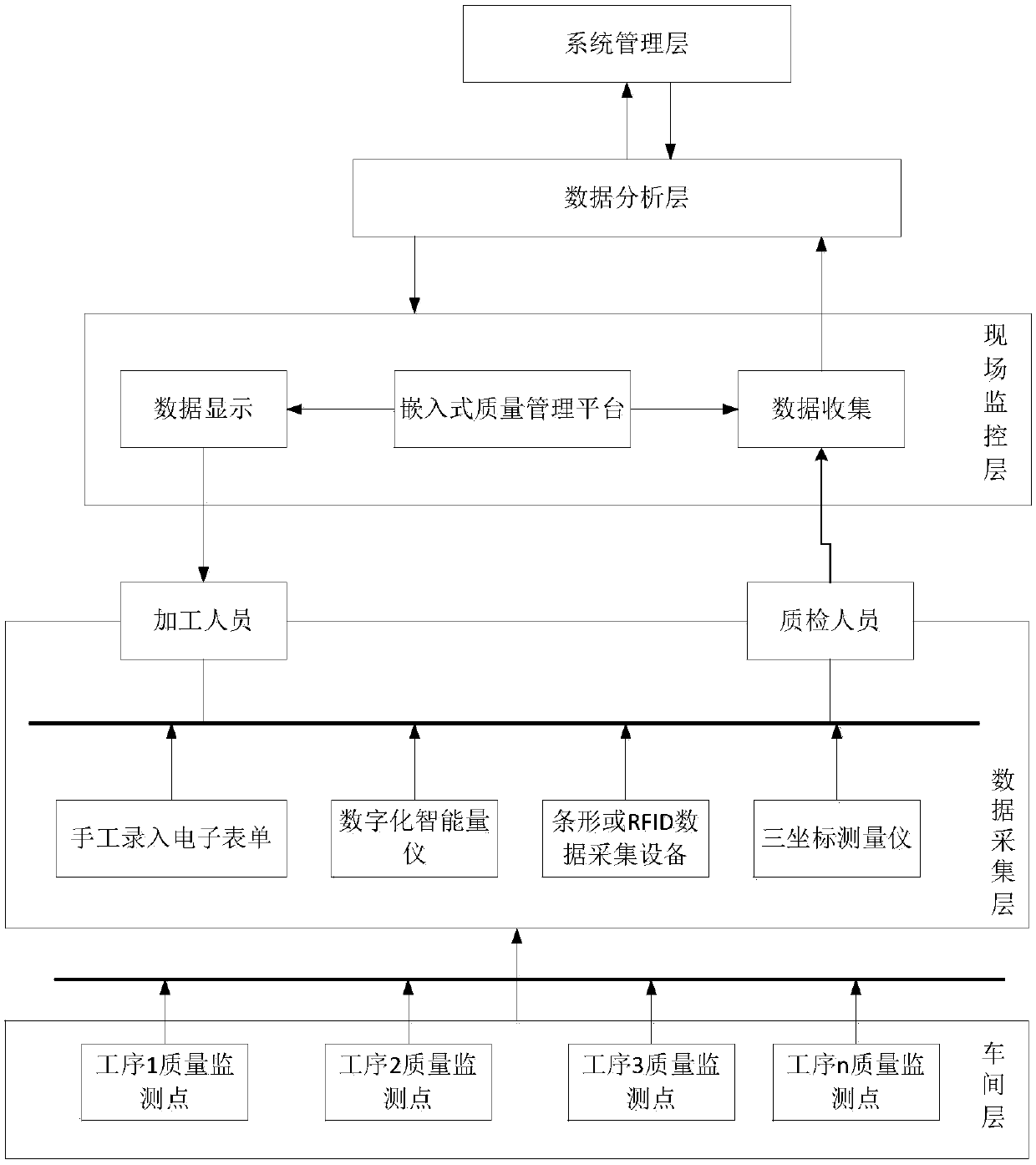

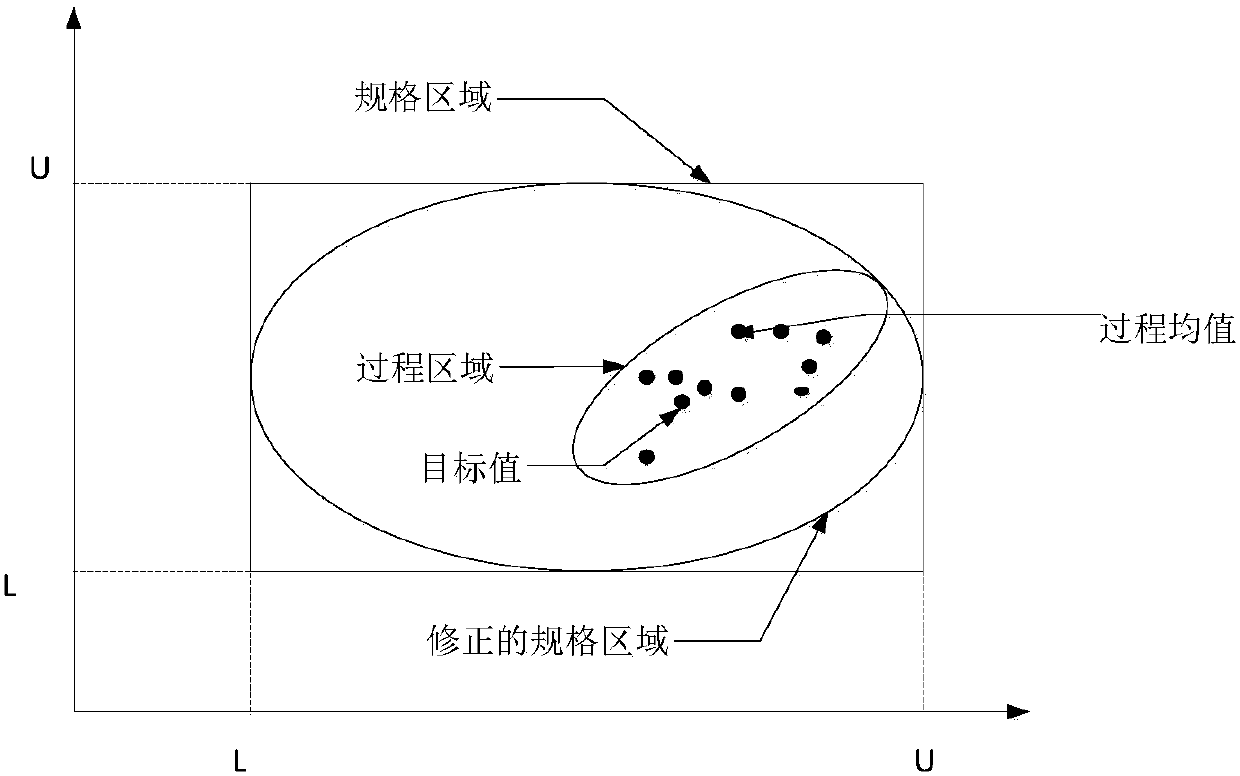

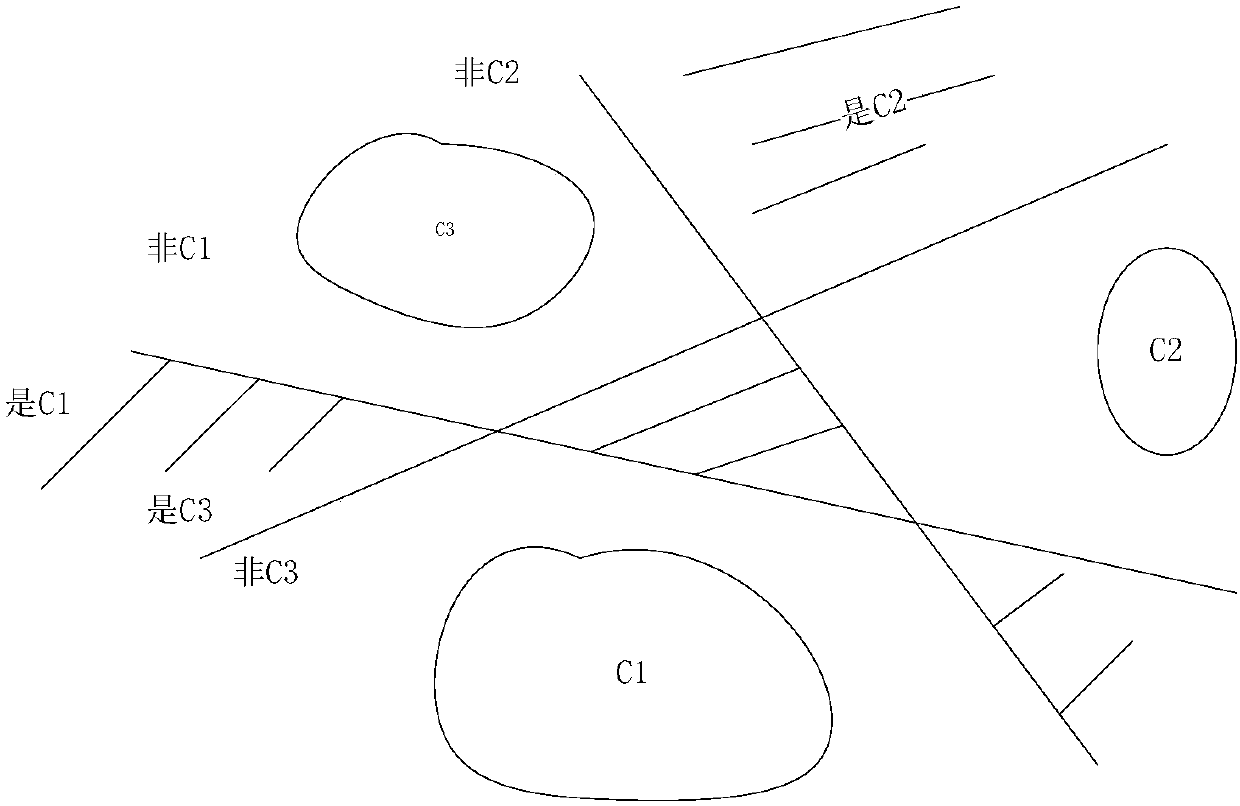

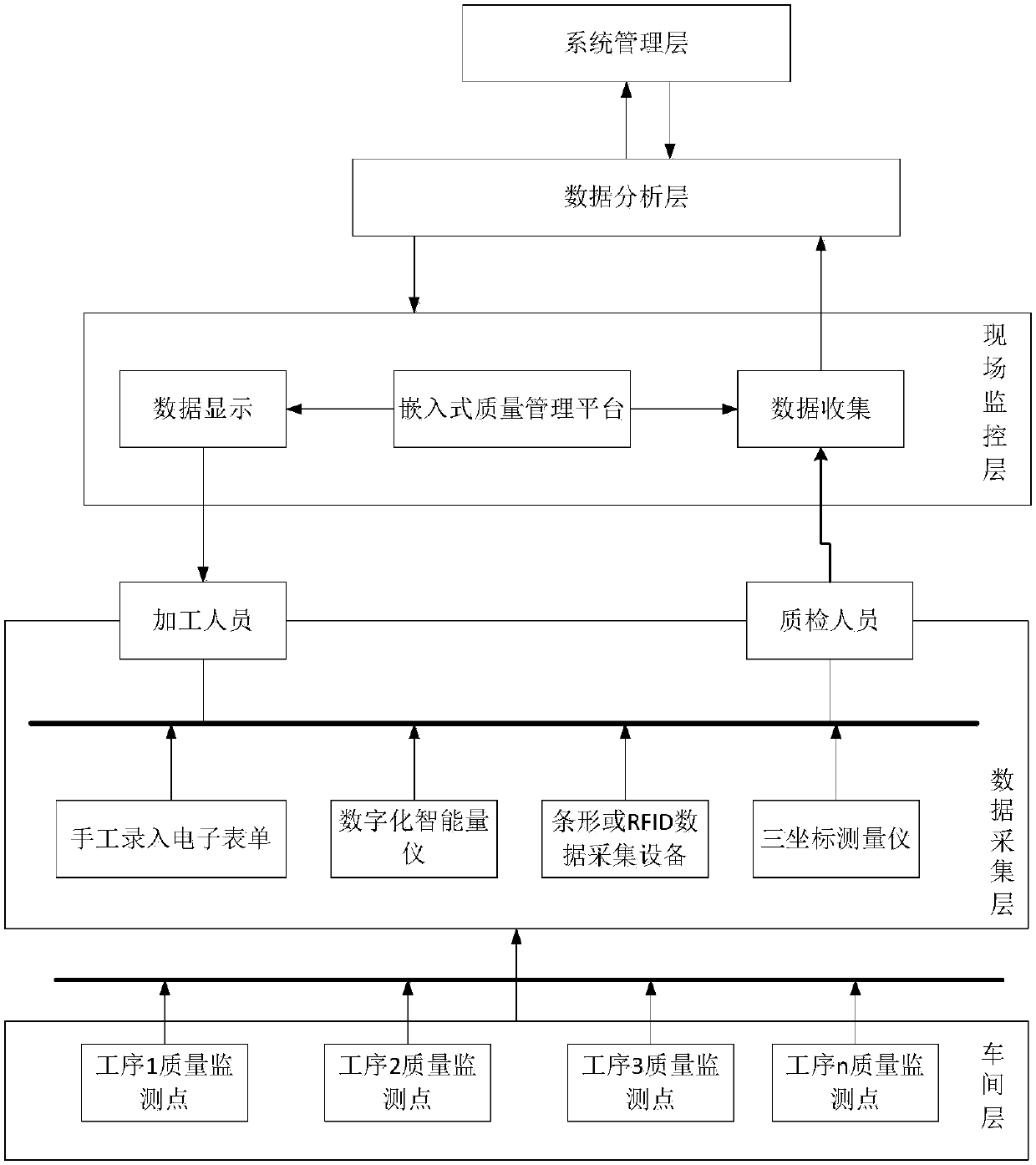

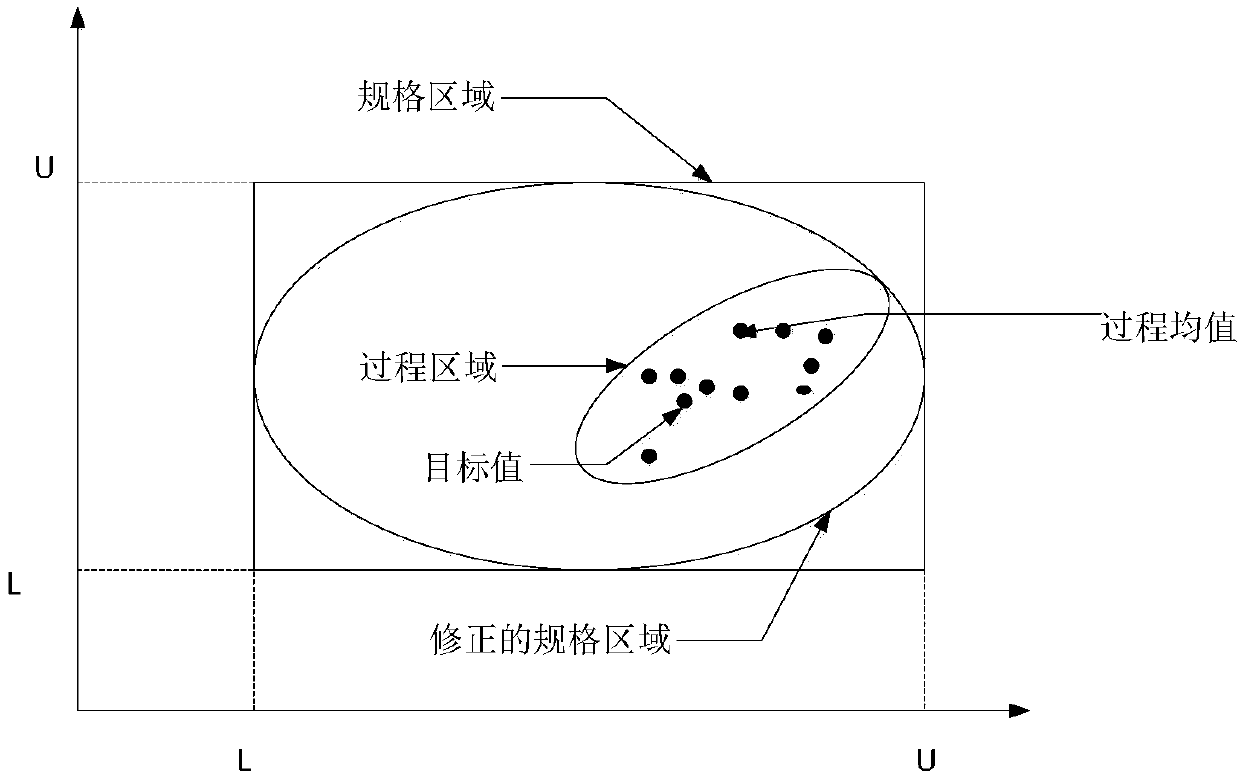

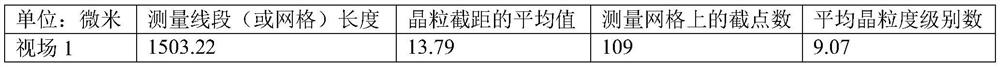

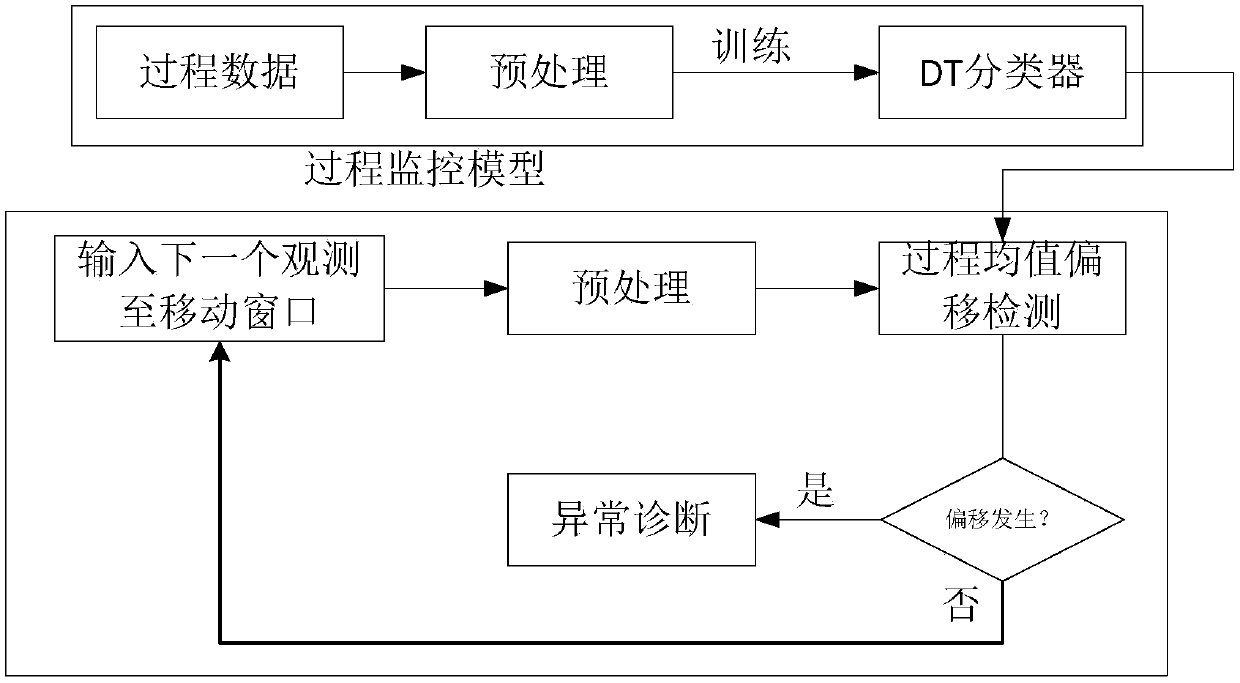

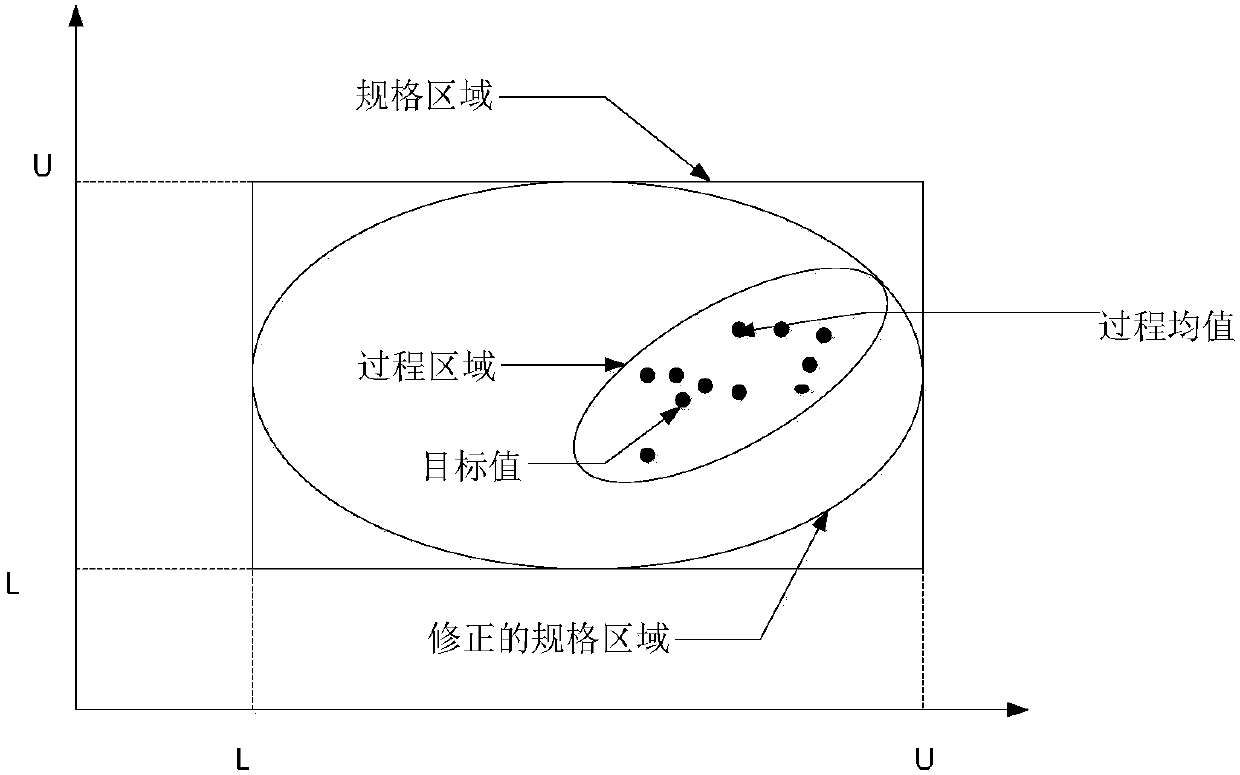

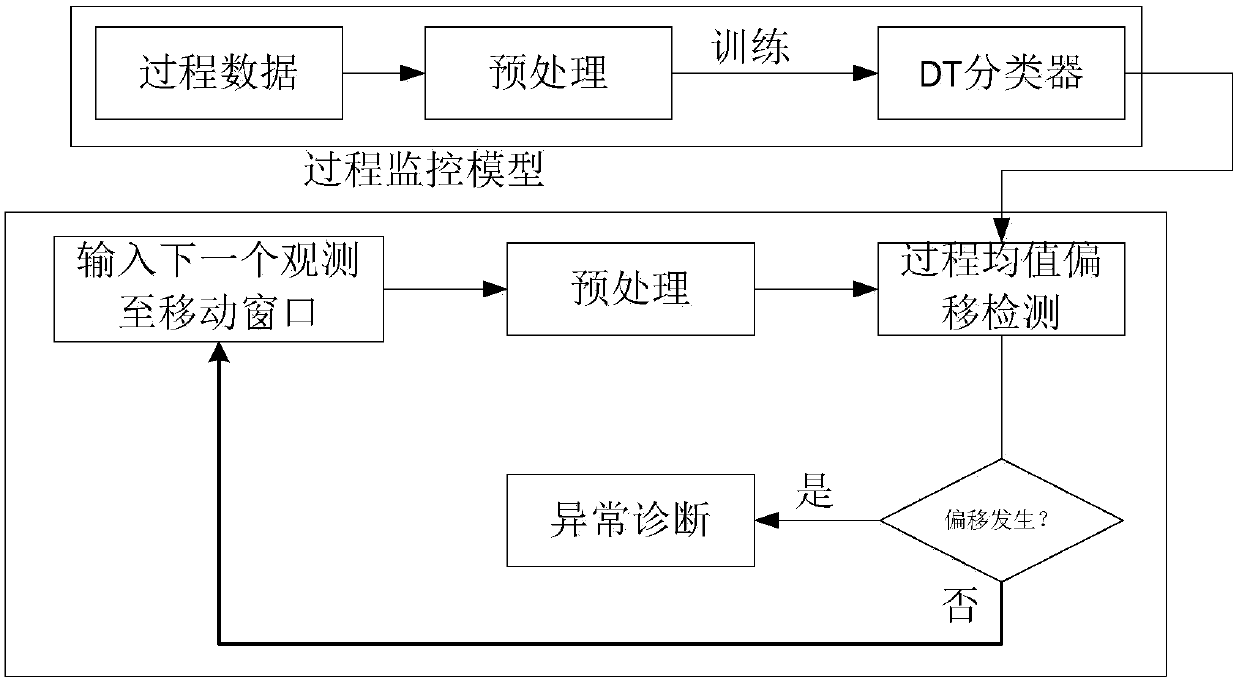

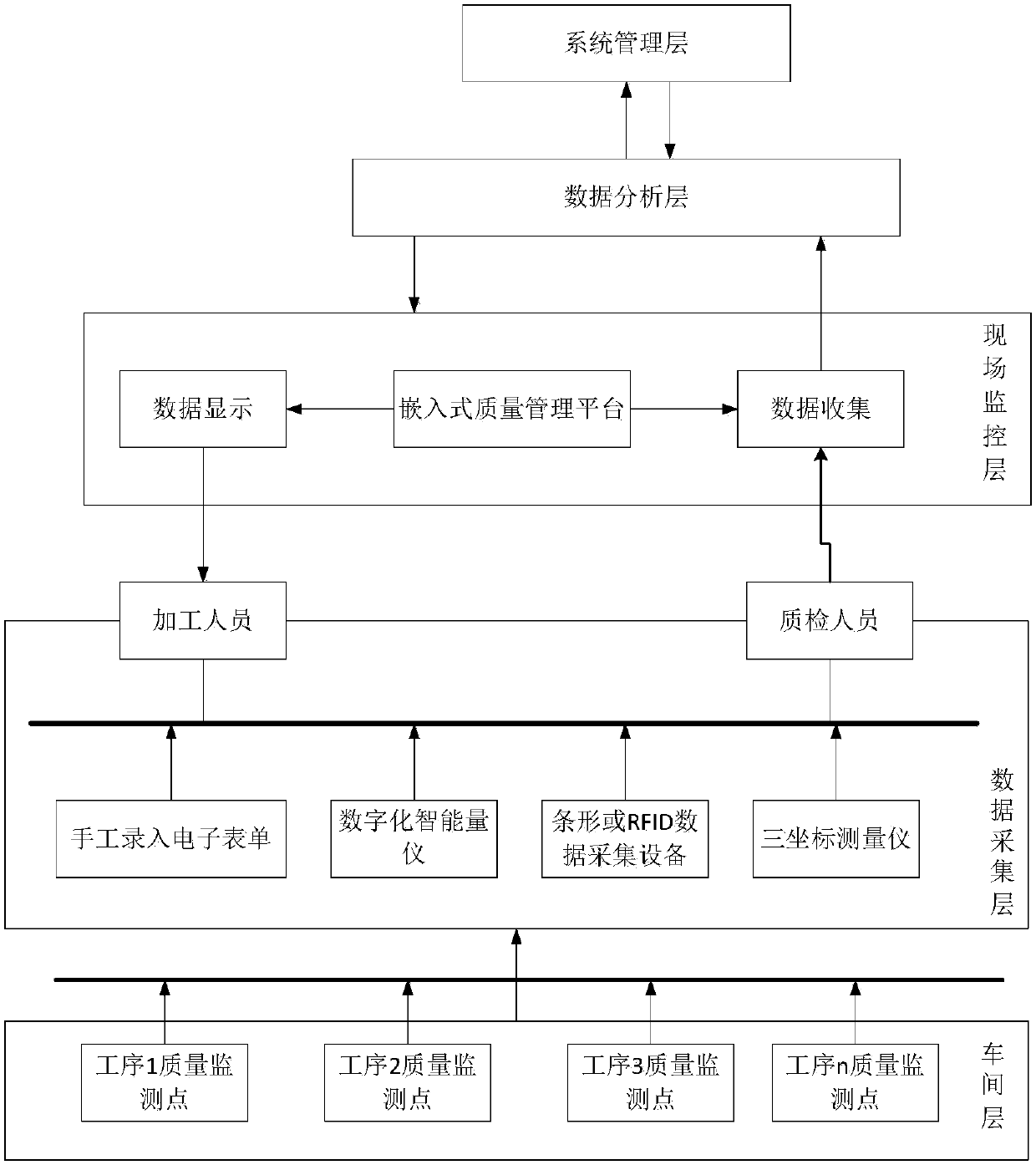

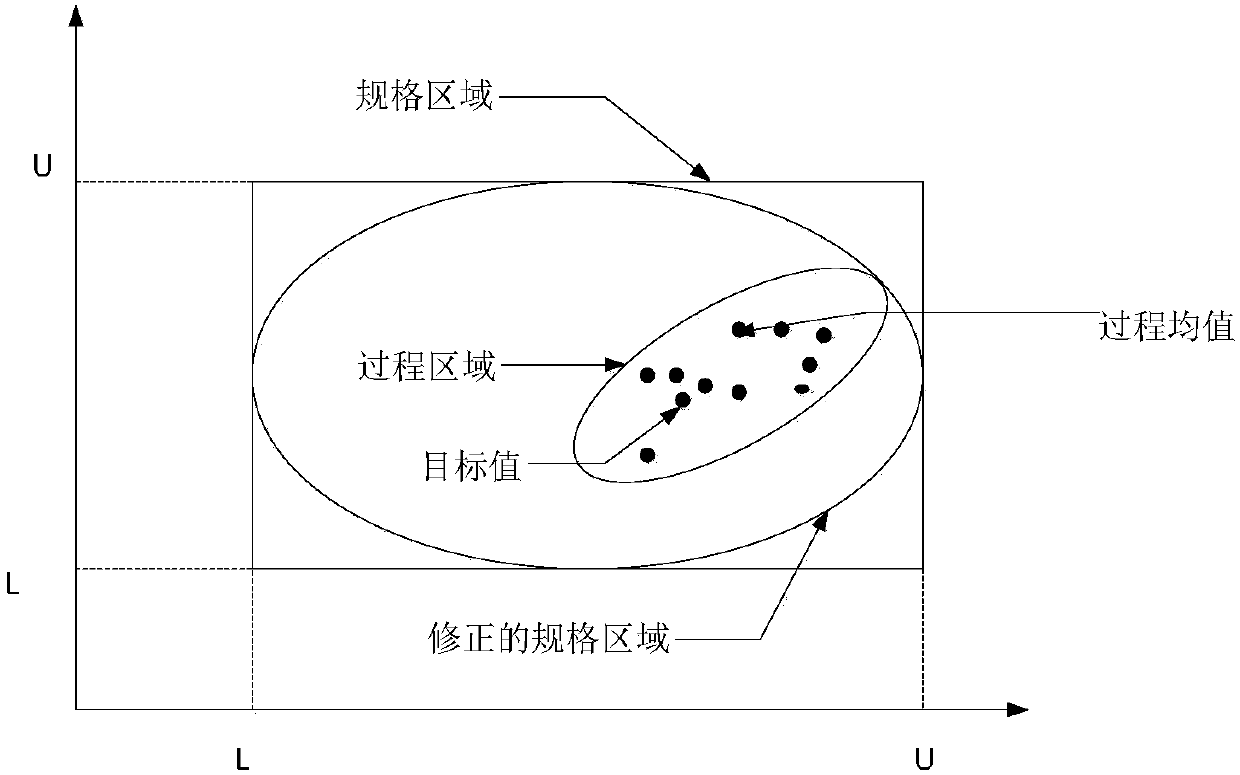

Manufacturing process multivariate quality diagnosis classifier based on improved fuzzy support vector machine

InactiveCN107346122AStrict conditionsJudgment status results are accurateProgramme controlComputer controlAlgorithm complexityControl chart

Provided is a manufacturing process multivariate quality diagnosis classifier based on an improved fuzzy support vector machine. Original data of quality characteristics in the manufacturing process is collected and preprocessed. A process analysis is made of the multivariate quality characteristics of key procedures using a hybrid algorithm. The stability and whether there is abnormality in the process are determined according to data recorded in a control chart. A process abnormality source is found using an improved fuzzy support vector machine method. In order to make the classification result more accurate, a membership factor and center point and boundary point correction are added to an objective function. The classifier has the advantages of rigorous process capability coefficient condition, accurate state judgment, low algorithm complexity and fast processing. Multivariate quality, misjudgment factor and principal component factor are integrated. The classifier is more adaptive. Parameter processing is standardized, and data processing is perfect. The probability of misjudgment is reduced. The problems of data bias and unit inconsistency are solved. Abnormality can be diagnosed.

Owner:SICHUAN YONGLIAN INFORMATION TECH CO LTD

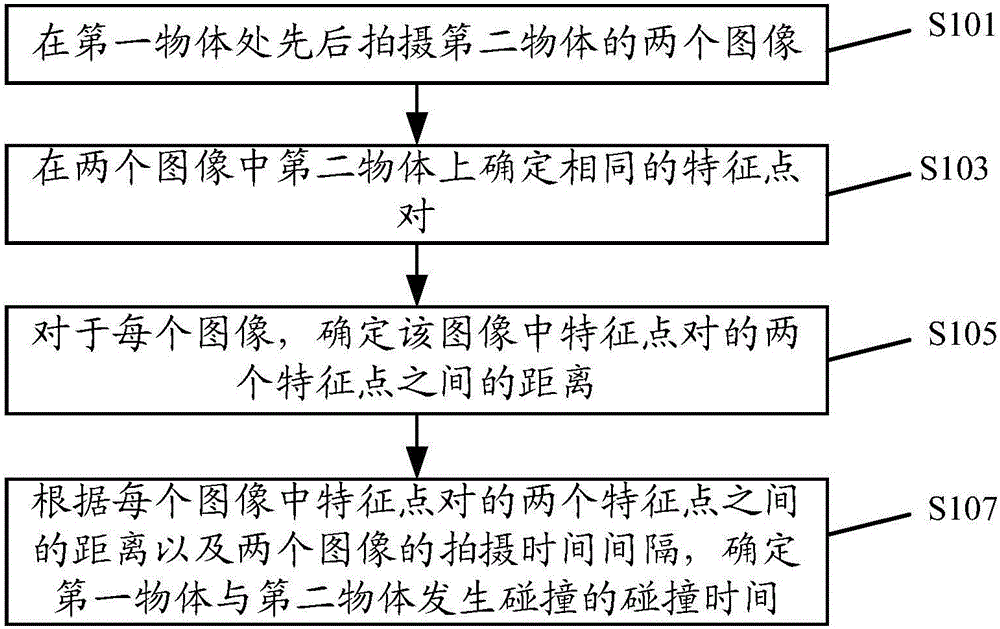

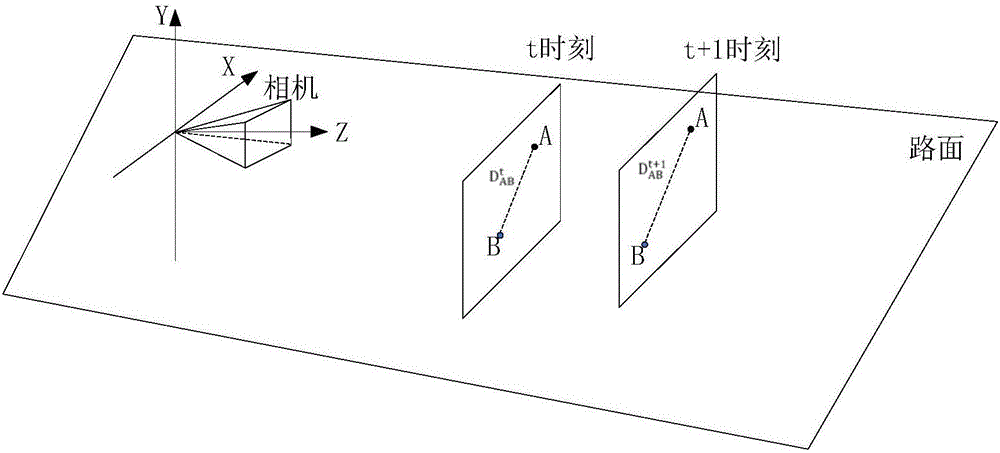

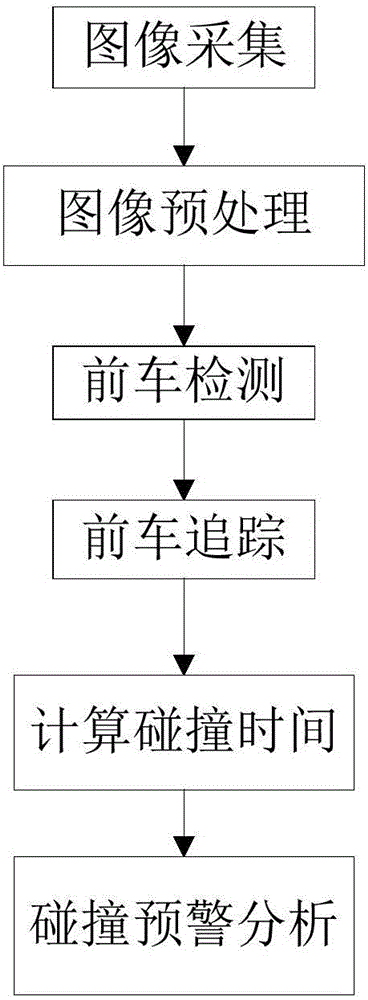

Method and device for predicting collision between objects

InactiveCN106570487AAccurate predictionImprove accuracyCharacter and pattern recognitionPower consumptionCollision risk

The invention discloses a method and a device for predicting the collision between objects. The method comprises the following steps: shooting two images of a second object at the position of a first object; determining an identical feature point pair on the second object in the two images; determining the distance between the two feature points of the feature point pair in each image; and determining the time of collision between the first object and the second object according to the distance between the two feature points of the feature point pair in each image and the shooting time interval of the two images. The predicted collision time can visually represent the collision risk at the current moment, and thus, drivers can be warned in a timely manner to perform a corresponding operation. Moreover, the method and the device have the advantages of high accuracy, good reliability, convenient use, low cost, low power consumption, and the like.

Owner:上海为森车载传感技术有限公司

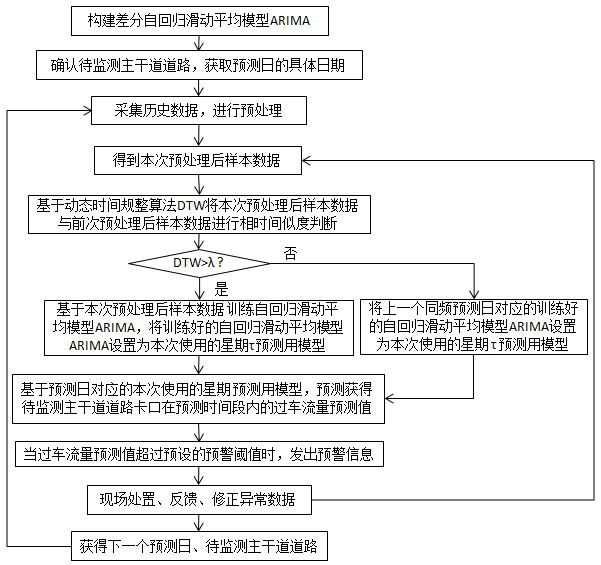

Checkpoint flow early warning method based on mobile police affairs

InactiveCN112330074AReduce training frequencyData is accurate and objectiveForecastingComplex mathematical operationsTraffic forecastSimulation

The invention provides a Checkpoint flow early warning method based on mobile police affairs, which can ensure that traffic polices can discover abnormal road sections in time, simplify the configuration process of Checkpoint flow early warning parameters by the traffic polices, and further ensure that the traffic polices can optimize Checkpoint distribution points and improve the operation and maintenance level of Checkpoint equipment. In the technical scheme of the invention, the traffic flow of the prediction day is predicted through the differential autoregressive moving average model ARIMA, and the traffic police can receive the early warning information before the traffic abnormality occurs once the traffic abnormality occurs by setting the early warning threshold, so that the traffic police can arrive at an abnormal place in time, and the problem is solved in time; based on historical data, a differential autoregressive moving average model ARIMA is established for a main trunkroad to be monitored on the basis of each day of a week, and it is ensured that a traffic flow passing predicted value predicted by the differential autoregressive moving average model ARIMA conformsto the characteristics of the peak value and valley value of the Checkpoint daily flow of each day in urban life.

Owner:TRAFFIC MANAGEMENT RES INST OF THE MIN OF PUBLIC SECURITY

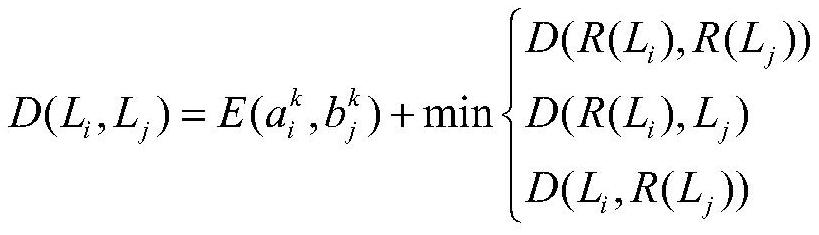

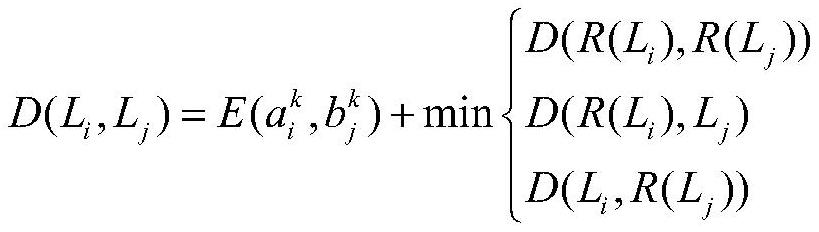

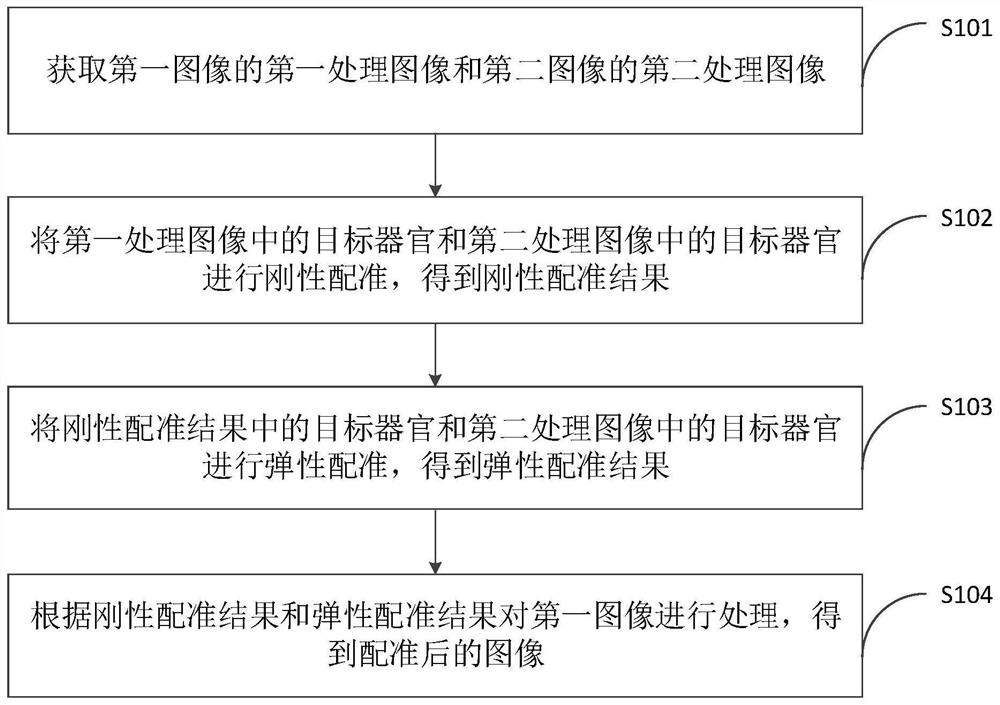

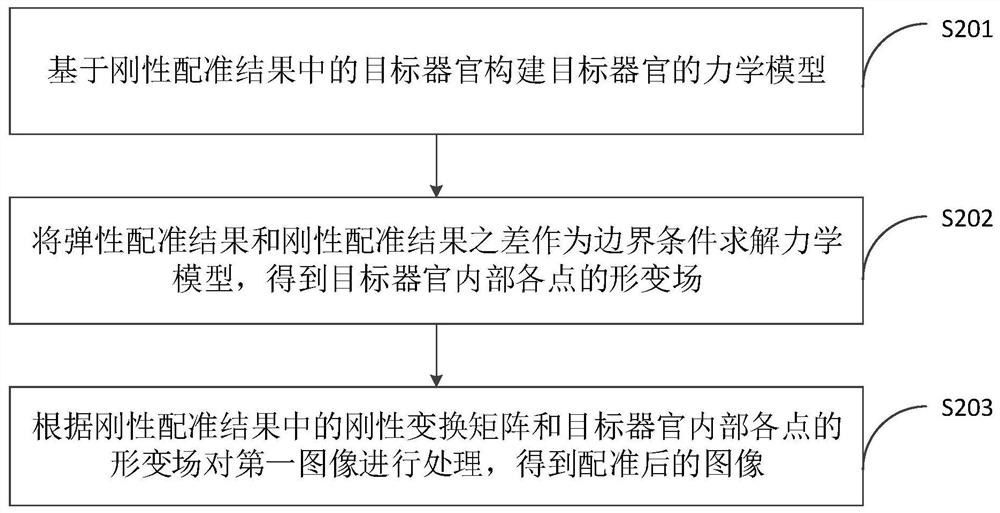

Tissue and organ registration method and device, computer equipment and storage medium

PendingCN113506331AAvoid inaccurate resultsImprove robustnessImage enhancementImage analysisRadiologyComputer vision

The invention relates to a tissue and organ registration method and device, computer equipment and a storage medium. The method comprises the following steps: acquiring a first processing image of a first image and a second processing image of a second image, and performing rigid registration on a target organ in the first processing image and a target organ in the second processing image to obtain a rigid registration result, and performing elastic registration on the target organ in the rigid registration result and the target organ in the second processing image to obtain an elastic registration result, and processing the first image according to the rigid registration result and the elastic registration result to obtain a registered image. According to the method, rich information of the target organ contained in the first image can be registered into the second image, registration is carried out based on the conversion relation of the feature points in the target organ, and compared with a traditional registration method that registration is carried out only based on the surface feature points of the target organ, the obtained registration result is more accurate, and the robustness is high.

Owner:WUHAN UNITED IMAGING HEALTHCARE SURGICAL TECH CO LTD

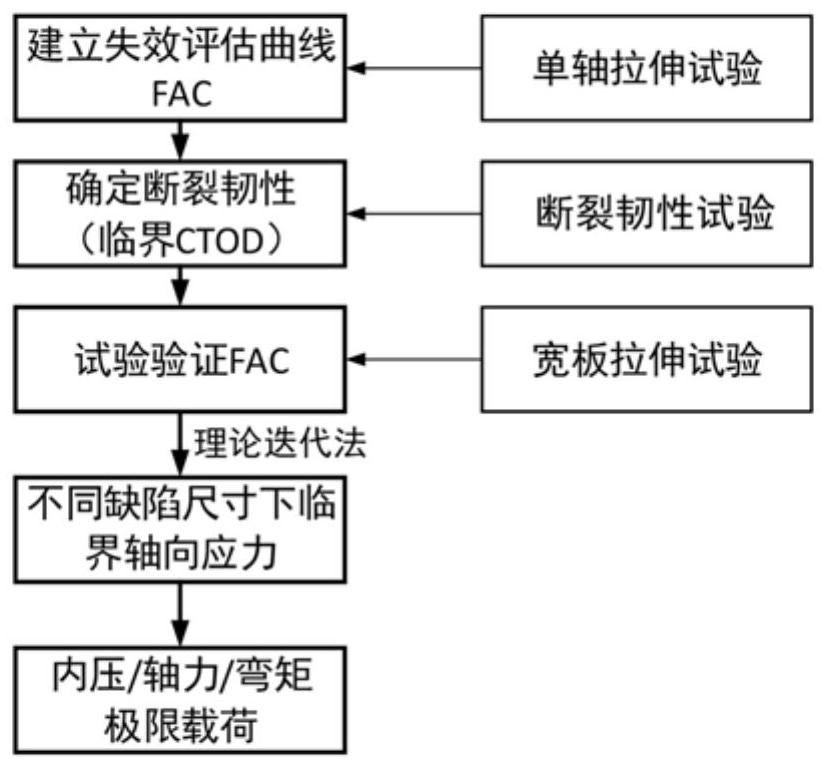

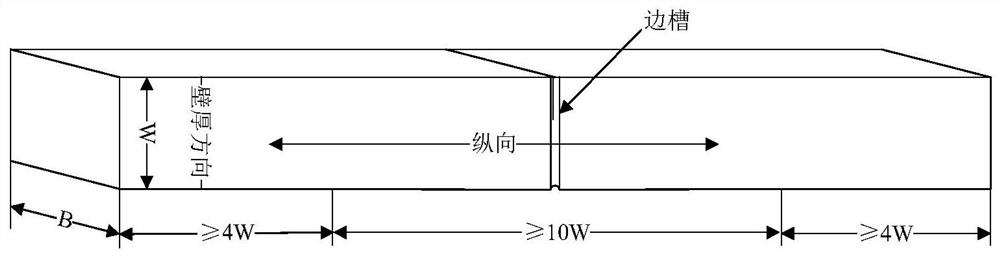

Method for evaluating ultimate load borne by buried pipeline with defects

ActiveCN112525692AAccurately reflect damage tolerance capabilityEliminate mismatchMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesStructural engineeringUltimate load

The invention discloses a method for evaluating an ultimate load borne by a buried pipeline with defects. The method comprises the following steps: step 1, performing a uniaxial tensile test on a pipeline sample, and calculating a failure evaluation curve; obtaining a critical CTOD value of the pipeline through a unilateral notch tensile test; and step 2, selecting the axial stress and defect sizeof the pipeline sample, and calculating a failure evaluation point through theoretical iterative calculation; if the failure evaluation point does not accord with the failure evaluation curve obtained in the step 1, performing recalculating until the failure evaluation points conform to the failure evaluation curve obtained in the step 1; and if the failure evaluation point conforms to the failure evaluation curve obtained in the step 1, calculating the internal pressure, bending moment and axial force limit load of the pipeline sample according to the critical axial stress and defect size. The limit value of the external load can be provided for predicting the pipeline failure behavior through the sensed pipeline load monitoring data, the pipeline safety service state is effectively mastered, and a basis is provided for pipeline safety early warning.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

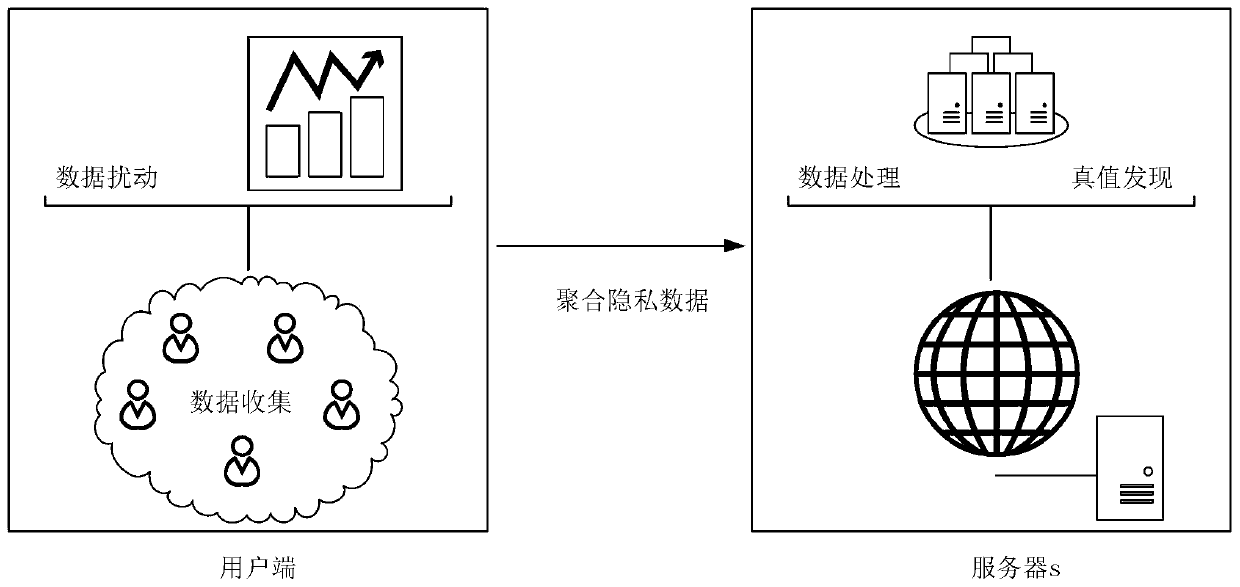

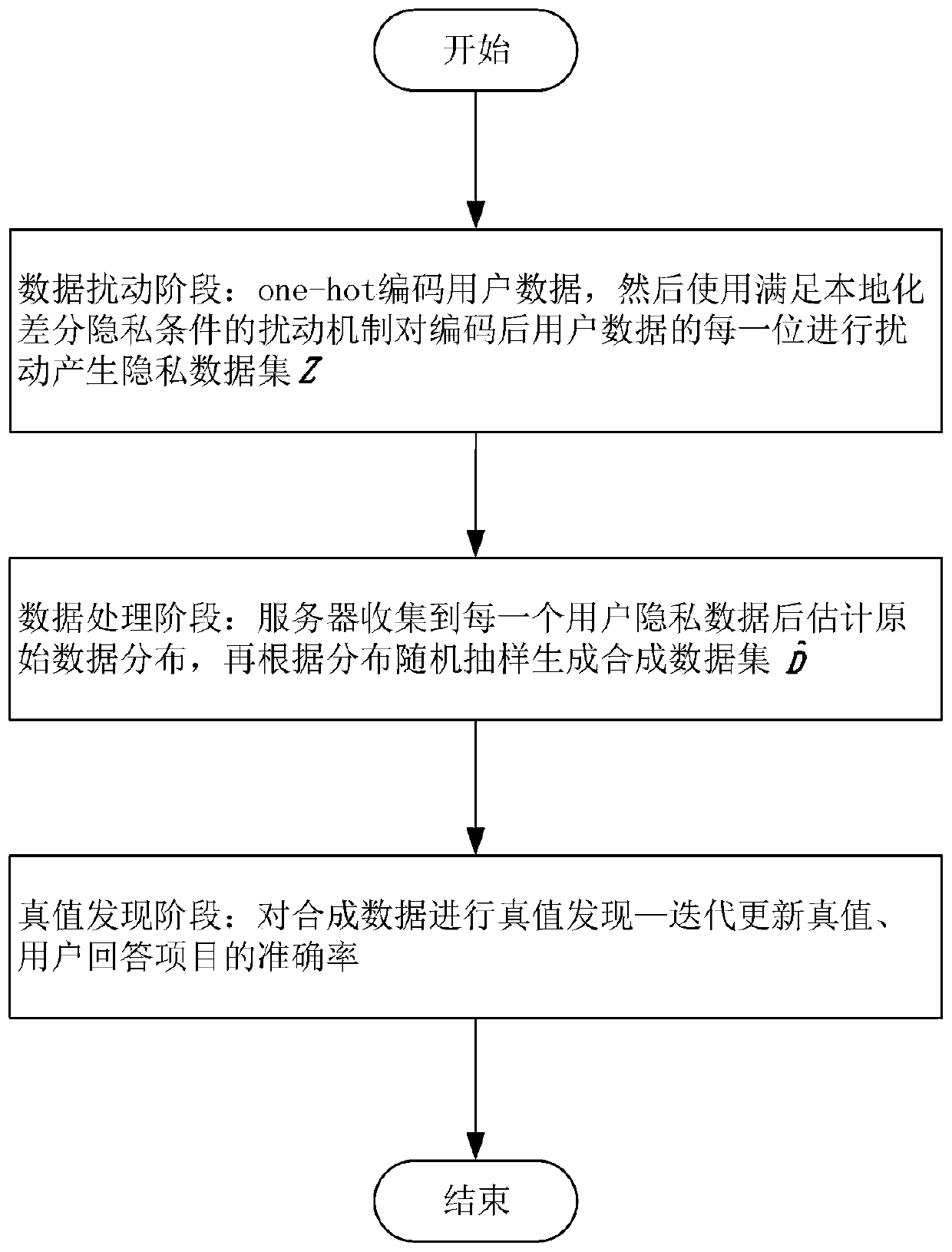

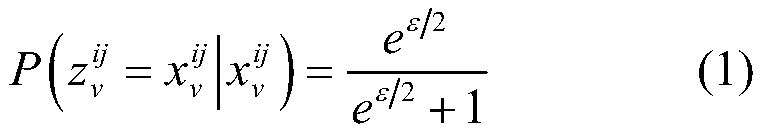

Multidimensional crowdsourcing data truth value discovery method based on localized differential privacy

The invention discloses a multidimensional crowdsourcing data true value discovery method based on localized differential privacy, which is applied to a crowdsourcing platform comprising n users, an untrusted server s and m projects, and is carried out according to the following steps of: 1, a data disturbance stage of disturbing crowdsourcing data answered by the users by using a random responsemechanism to generate private data; 2, a private data processing stage of processing private data to generate estimated synthetic data; and 3, a truth value discovery stage of performing truth value discovery on the estimated synthetic data to obtain a final accurate answer. According to the invention, data protection is carried out on data of a user by using a strong privacy protection mechanism-localization differential privacy; and information leakage is prevented, through utilizing truth value discovery, result inaccuracy caused by conflicts among the data and inconsistent user quality issolved, truth value updating accuracy is guaranteed, and user privacy and data availability can be guaranteed in the crowdsourcing platform.

Owner:ANHUI UNIVERSITY

SVM-based multivariate quality diagnosis classifier for manufacturing process

InactiveCN107992006AStrict process capability coefficient conditionsJudgment status is accurateTotal factory controlProgramme total factory controlOriginal dataProcess capability

Disclosed is an SVM-based multivariate quality diagnosis classifier for a manufacturing process. Original data of quality characteristics in the manufacturing process is collected and pre-processed, ahybrid algorithm is applied for conducting process analysis on multivariate quality characteristics of a key procedure, stability and anomalies are judged according to data recorded by a control chart, and a support vector machine method is applied for finding out where a source of the process anomalies is, so that a classification result is more accurate, and relaxation factors are added in an objective function by means of a Lagrangian optimization method. The classifier has the advantages that the process capability coefficient condition is strict, the judgement state is accurate, the algorithm complexity is low, the processing time is short, multivariate quality, misjudgment factors and principal component factors are integrated, the applicability is higher, parameter processing is standardized, data processing is improved, the misjudgment probability is reduced, the problems of data offset and unit inconsistency are solved, and an anomaly diagnosis technology can be achieved.

Owner:SICHUAN YONGLIAN INFORMATION TECH CO LTD

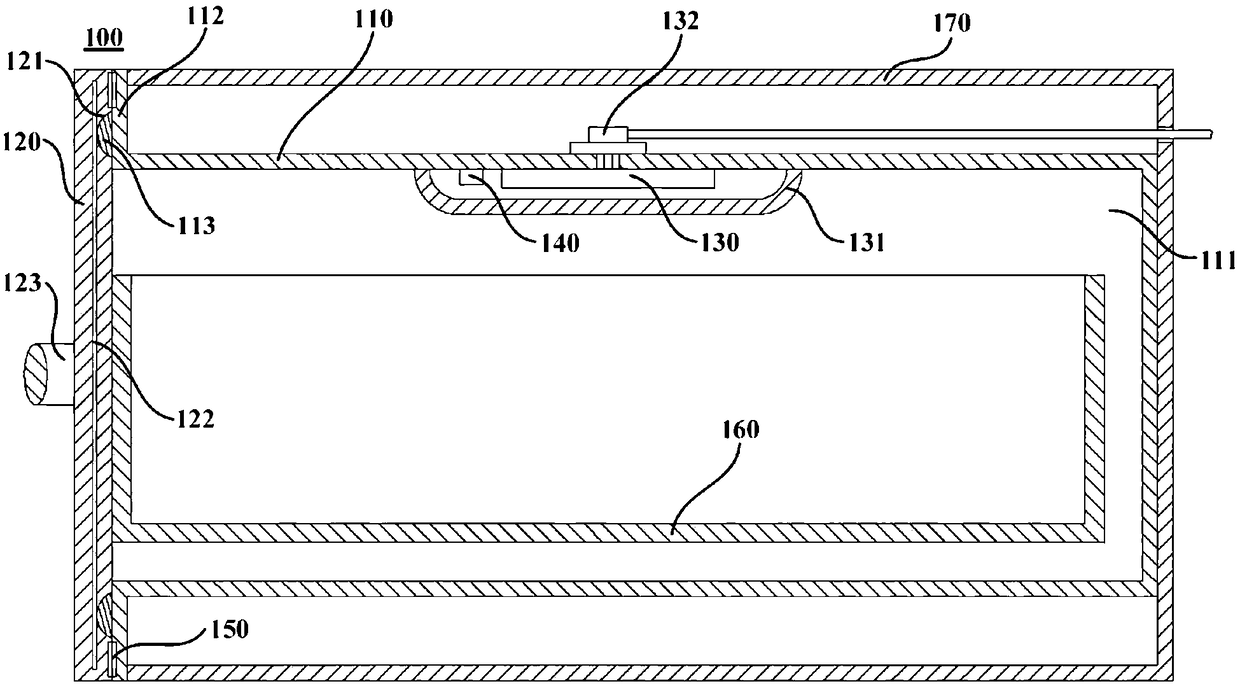

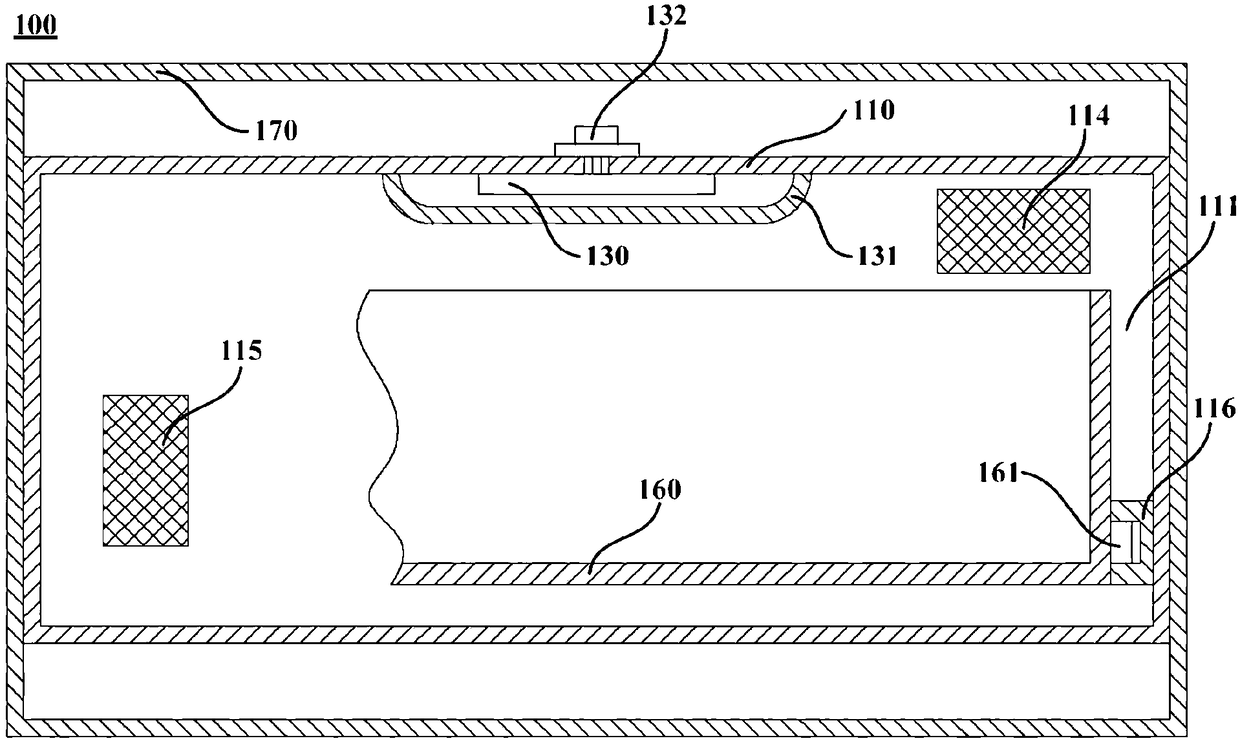

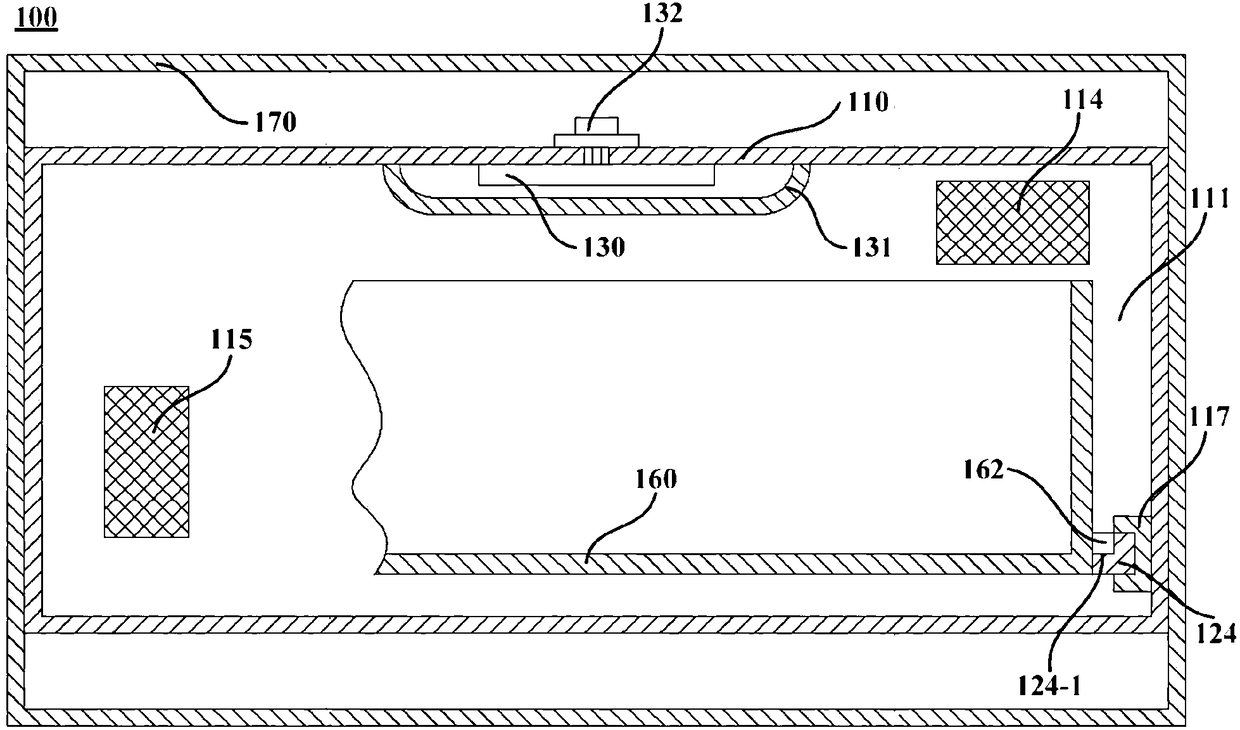

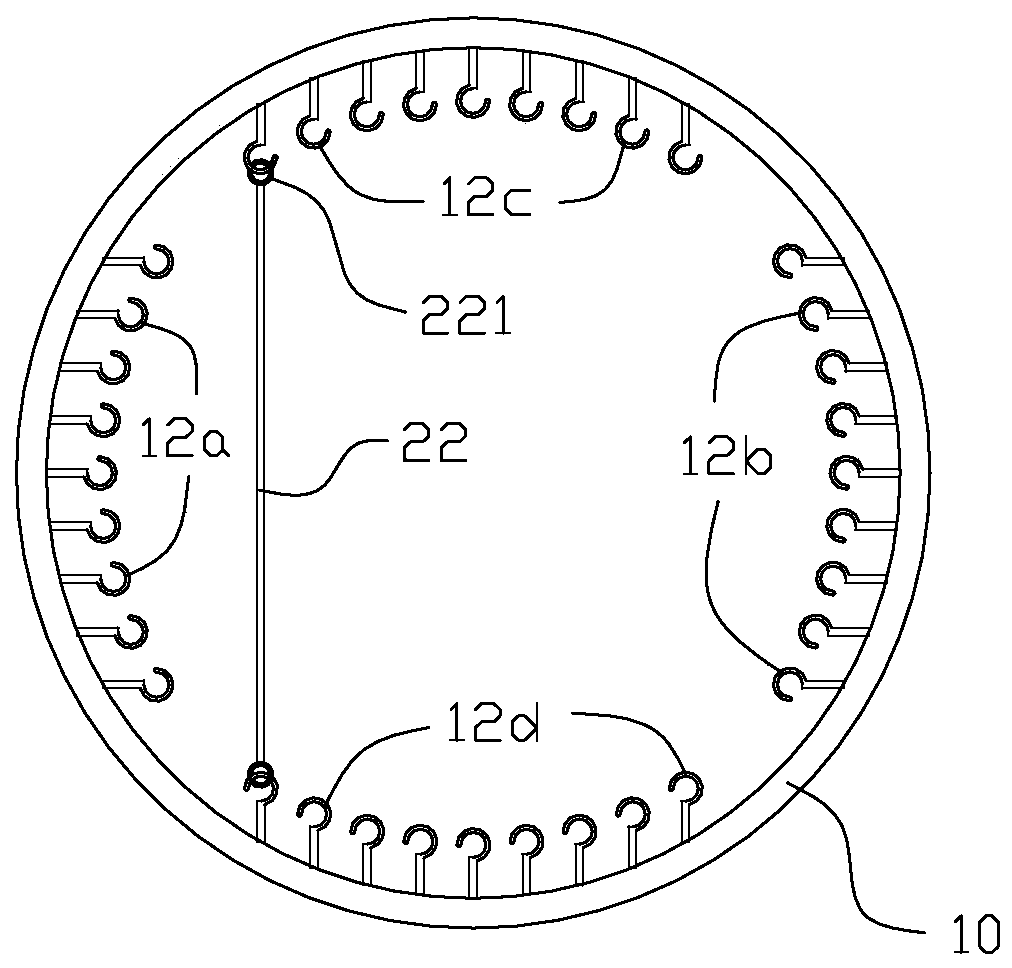

Control method used for unfreezing device

PendingCN109323523AImprove thawing efficiencyImprove convenienceDomestic cooling apparatusLighting and heating apparatusElectricityRadio frequency signal

The invention provides a control method used for an unfreezing device. The unfreezing device comprises a barrel, a device door body, a radio frequency generation module and a radio frequency antenna.An unfreezing cavity used for containing a to-be-processed object is defined in the barrel. The device door body is arranged at the position of a picking and placing opening of the unfreezing cavity and used for opening and closing the picking and placing opening of the unfreezing cavity. The radio frequency antenna is arranged at the position of the inner wall of the unfreezing cavity and electrically connected with the radio frequency generation module. The control method includes the steps that the optimal unfreezing frequency for unfreezing the to-be-processed object placed in the unfreezing cavity is confirmed; the radio frequency generation module generates a radio frequency signal with the frequency being the optimal unfreezing frequency; and the radio frequency antenna generates radio frequency waves with the corresponding frequency in the unfreezing cavity according to the radio frequency signal, and the to-be-processed object is unfrozen. According to the control method, by confirming the optimal unfreezing frequency for unfreezing the to-be-processed object and making the radio frequency generation module generate the radio frequency signal with the frequency being the optimal unfreezing frequency to unfreeze the to-be-processed object, the unfreezing frequency is improved, the unfreezing time is shortened, and then the unfreezing convenience is improved for users.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

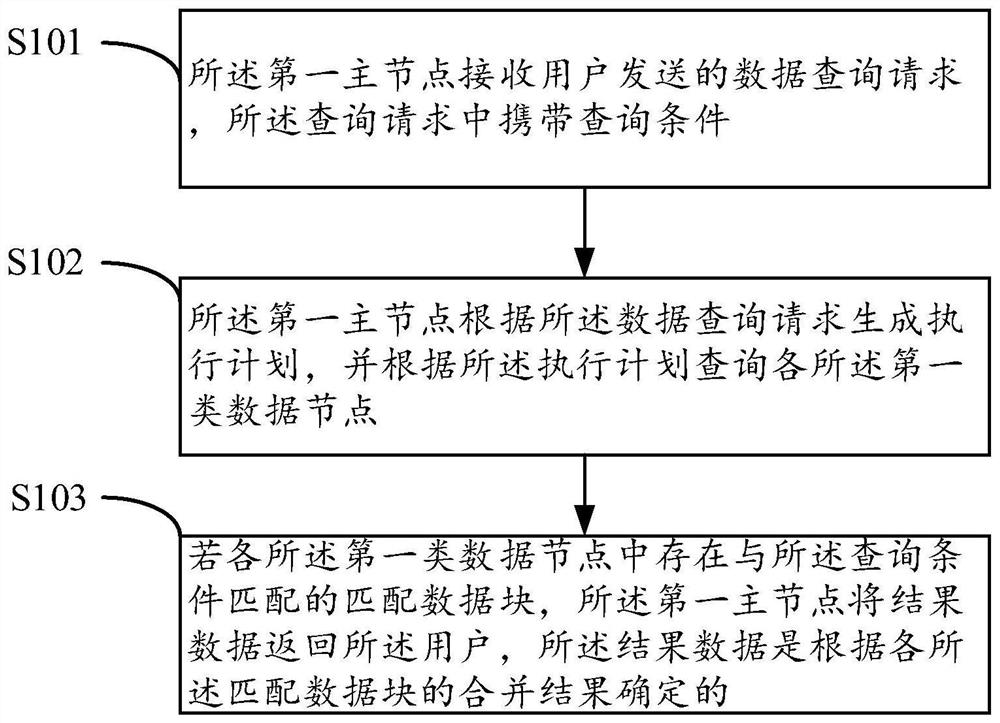

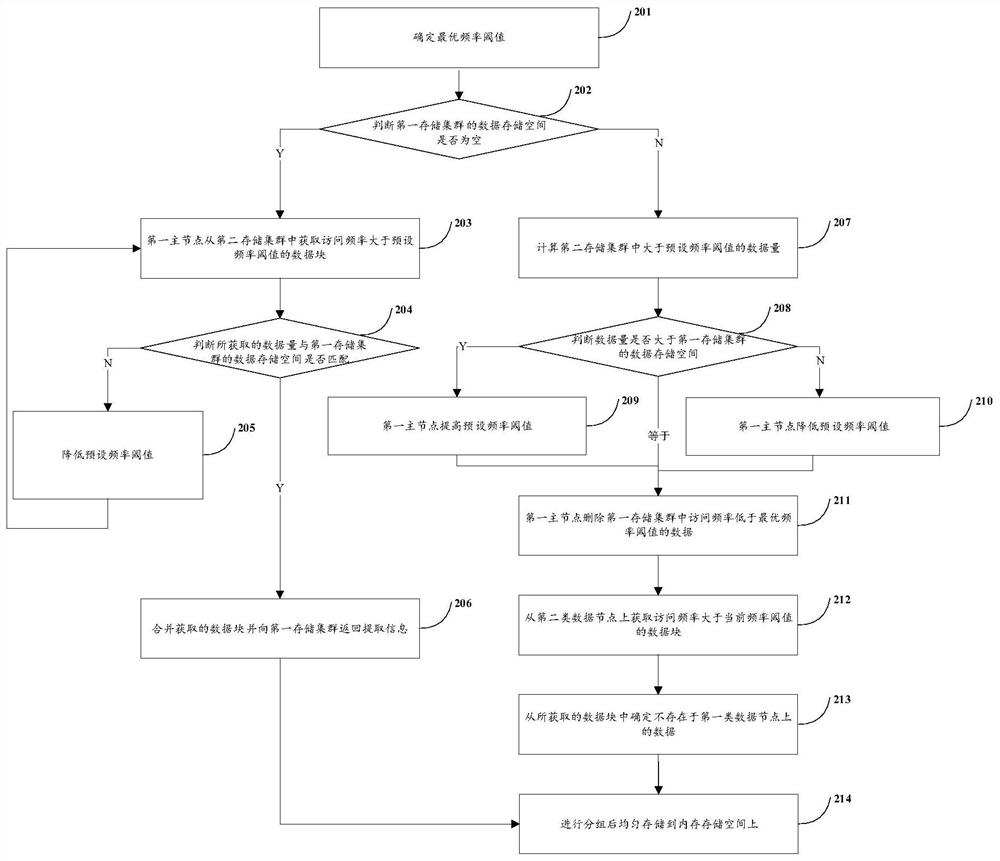

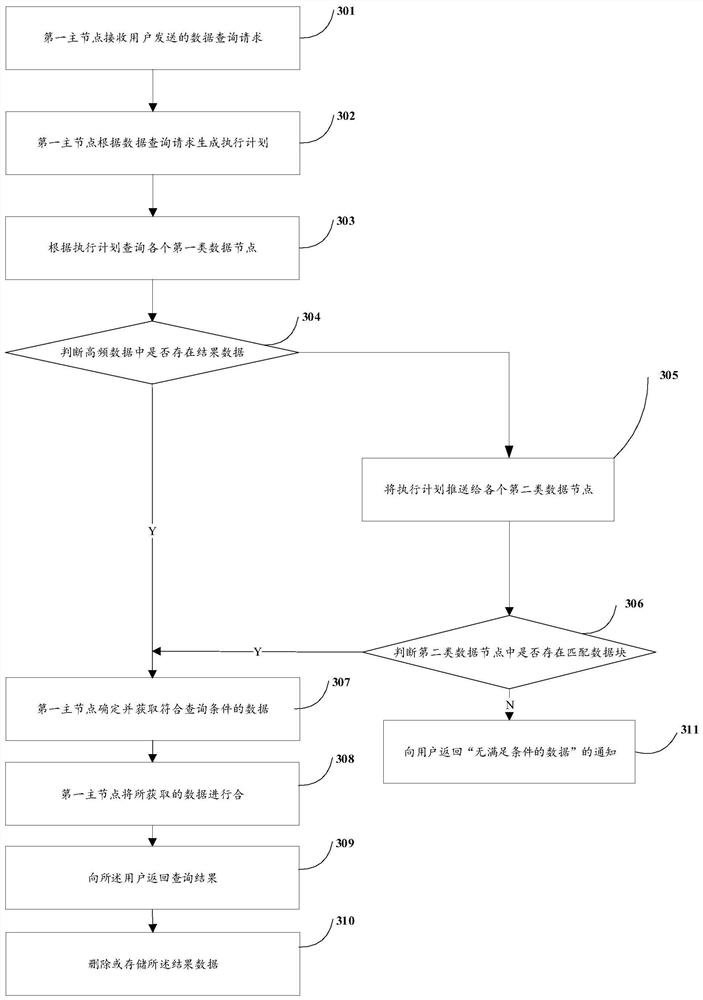

Method and equipment for accelerating data parallel query based on high-frequency data processing

ActiveCN111858657AParallel query performance improvementImprove response speedDigital data information retrievalSpecial data processing applicationsExecution planAccess frequency

The invention discloses a method and equipment for accelerating data parallel query based on high-frequency data processing, and the method comprises the steps that a first main node receives a data query request sent by a user, and the query request carries a query condition; the first main node generates an execution plan according to the data query request, and queries each first type of data node according to the execution plan; if a matching data block matched with the query condition exists in each first type of data node, the first main node returns result data to the user, and the result data is determined according to a merging result of each matching data block, wherein the high-frequency data is data of which the access frequency is greater than a preset frequency threshold in the first main node, so that the big data parallel processing capability and the query efficiency are improved.

Owner:BORRUI DATA TECH (BEIJING) CO LTD

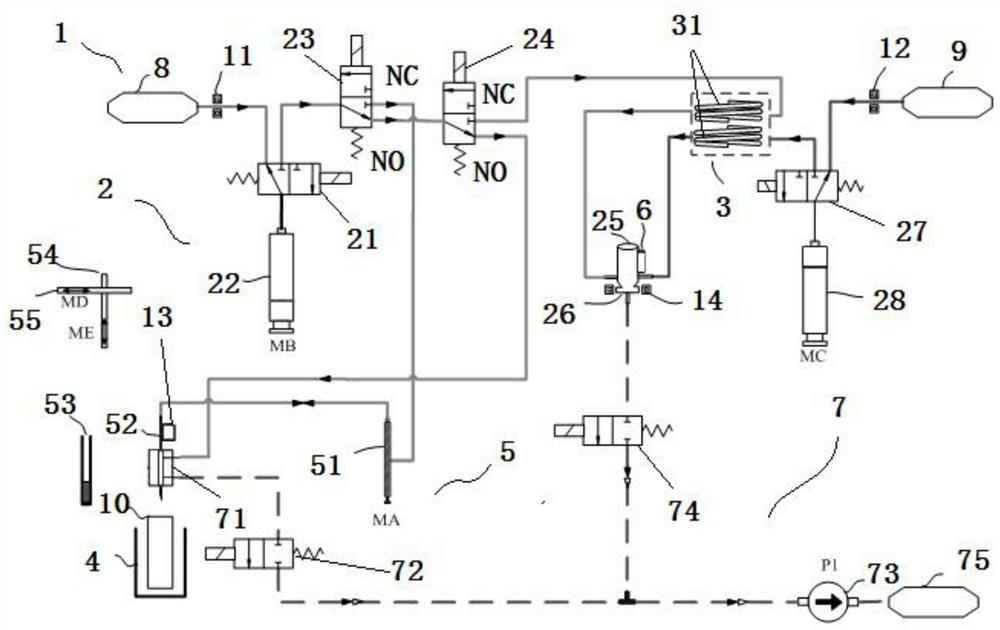

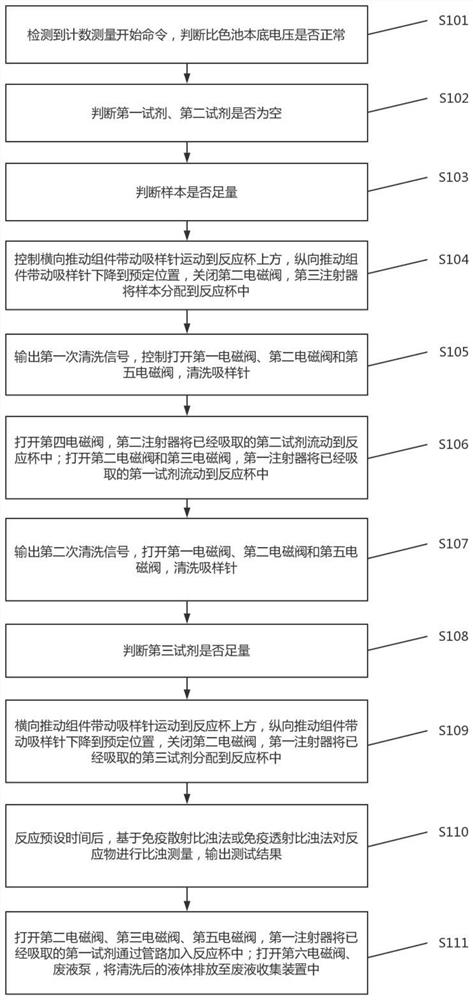

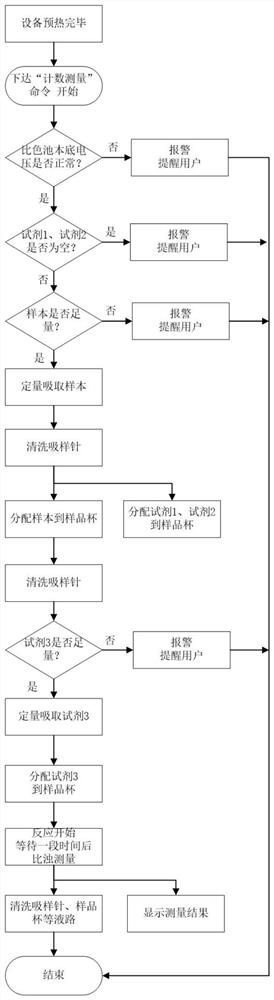

Liquid path system based on immunoturbidimetry measurement and control method thereof

The invention discloses a liquid path system based on immunoturbidimetry measurement and a control method thereof.According to the method, one injector corresponds to one liquid pipeline, and independent sample, reagent and filling functions are realized; a sample or a reagent is detected through the liquid level detection device before the sample or the reagent is sucked, and the sample is suckedonly after enough sample or reagent is detected, so problems of empty sample suction and semi-empty sample suction are solved, inaccurate results are avoided, and the waste of the sample and the reagent is avoided; the reagent preheating module is used for preheating the reagent before the reagent enters the reaction cup, so a more accurate measurement result is realized; whether a reagent existsor not is detected through the first detection sensor and the second detection sensor, inaccurate results are avoided, and waste of samples and reagents is avoided; high-precision absolute counting measurement is realized by adopting a quantitative technology; and meanwhile, a liquid path is simplified, the control flow is simplified, cost is reduced, and maintenance is convenient.

Owner:URIT MEDICAL ELECTRONICS CO LTD

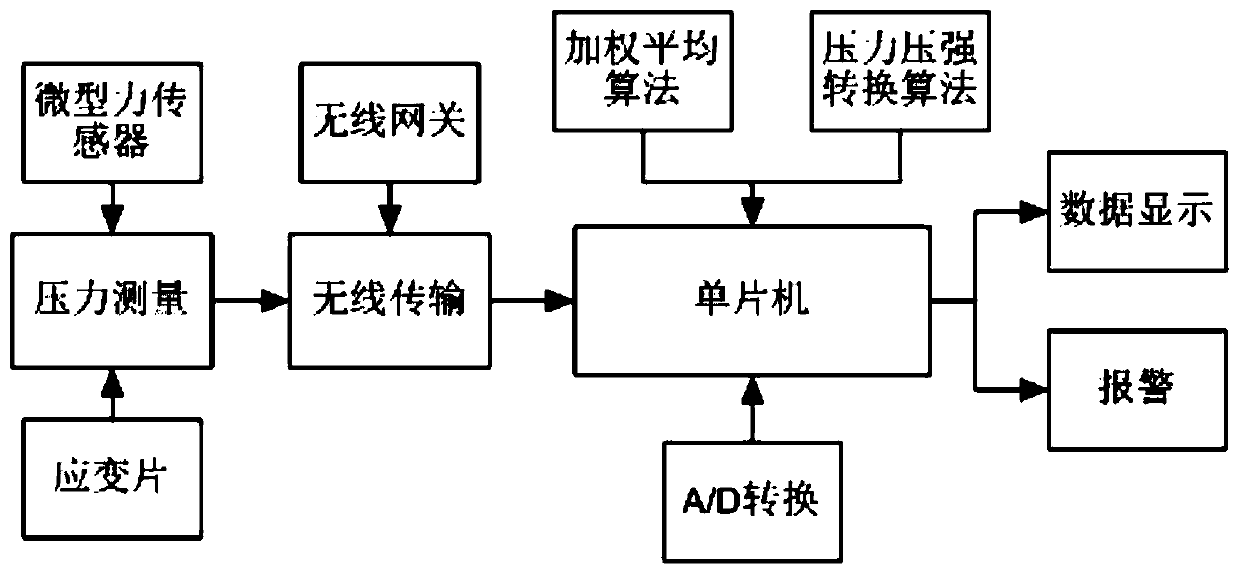

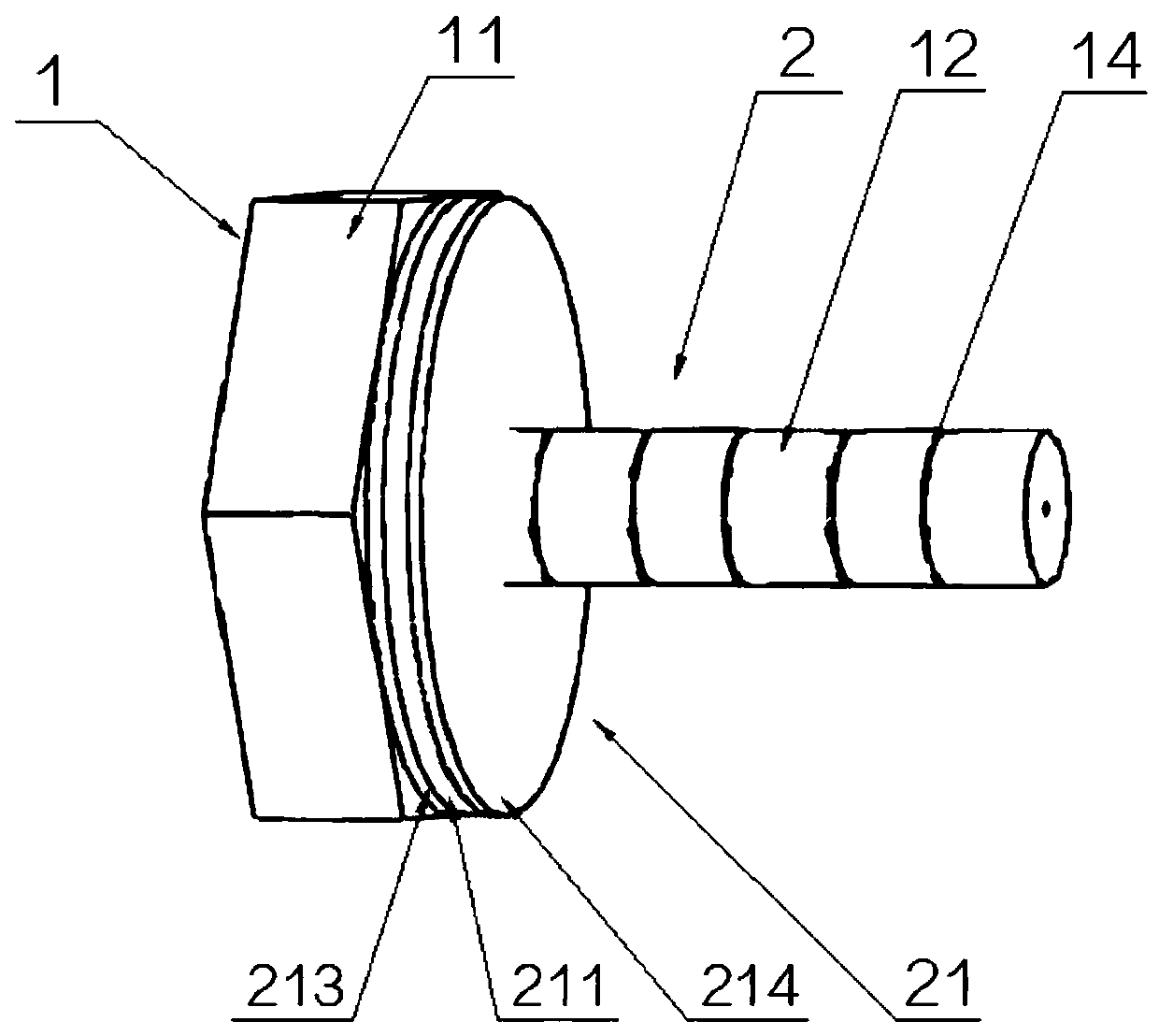

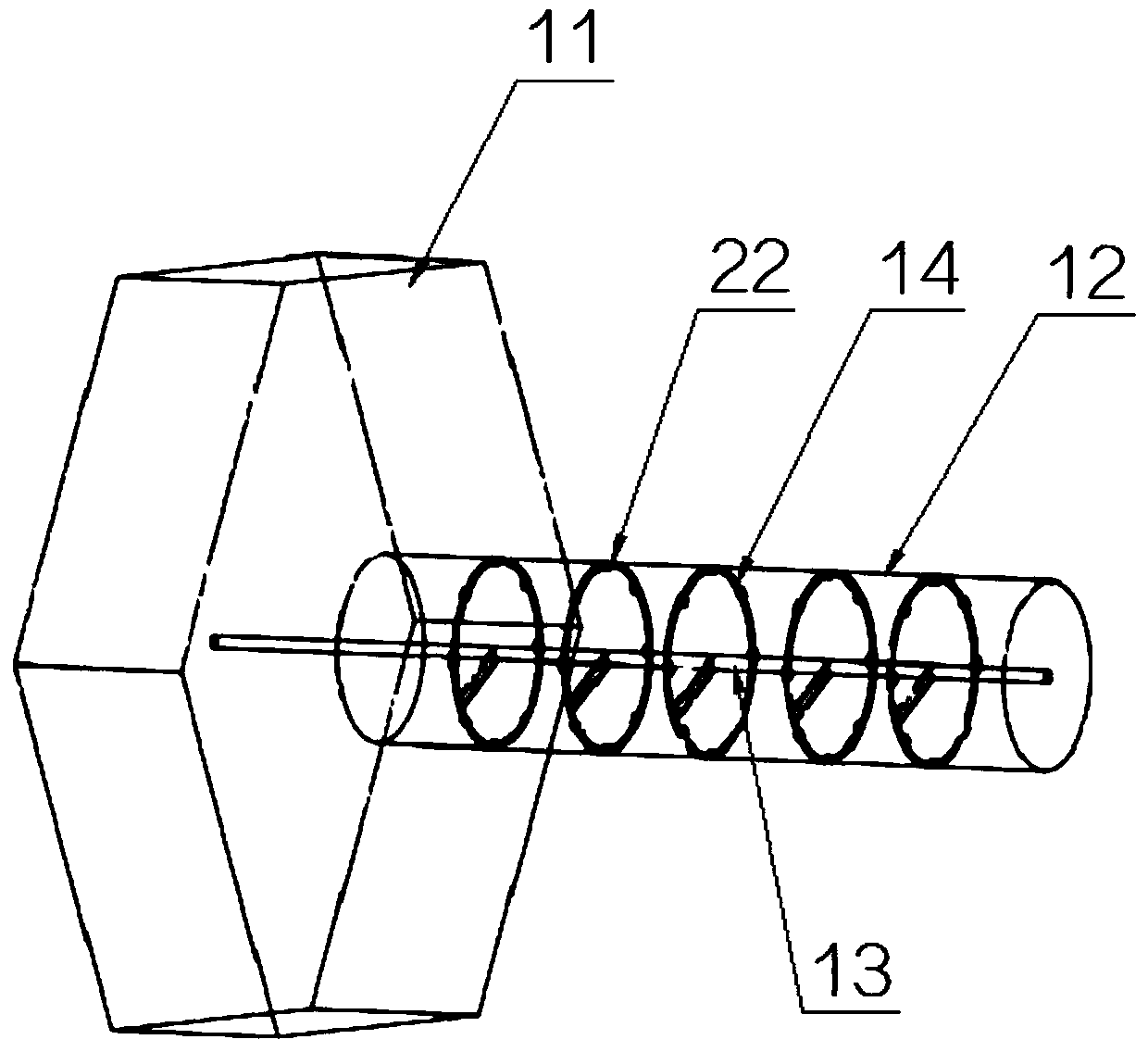

Bolt structure capable of measuring pressure and pressure intensity in real time

InactiveCN111059123AEasy to measureAvoid inaccurate resultsTransmission systemsFluid pressure measurementData displayWireless transmission

The invention discloses a bolt structure capable of measuring pressure and pressure intensity in real time. The bolt structure comprises a force measuring bolt, a pressure measuring module, a wirelesstransmission module, a single-chip microcomputer module and a data display module. The force measuring bolt comprises a bolt head part and a bolt rod part. The bolt head part and the bolt rod part are provided with through wire through holes. The bolt rod part is provided with a plurality of patch grooves at intervals along the axial direction. The pressure measuring module comprises a head forcemeasuring unit and a rod force measuring unit. The head force measuring unit comprises a gasket. A micro force sensor array is arranged on the gasket. The rod force measuring unit comprises a plurality of strain gauges, and the strain gauges are arranged in the patch grooves. According to the invention, the head of the bolt adopts a miniature force sensor array; the rod part of the bolt adopts strain gauge bridges arranged in the patch grooves, and the other parts of the rod part of the bolt except the patch grooves adopt fastening threads; the two are effectively combined, and the functionsof connection and force measurement are achieved; the accuracy of force measurement can be guaranteed; and low cost can be guaranteed.

Owner:NANCHANG UNIV

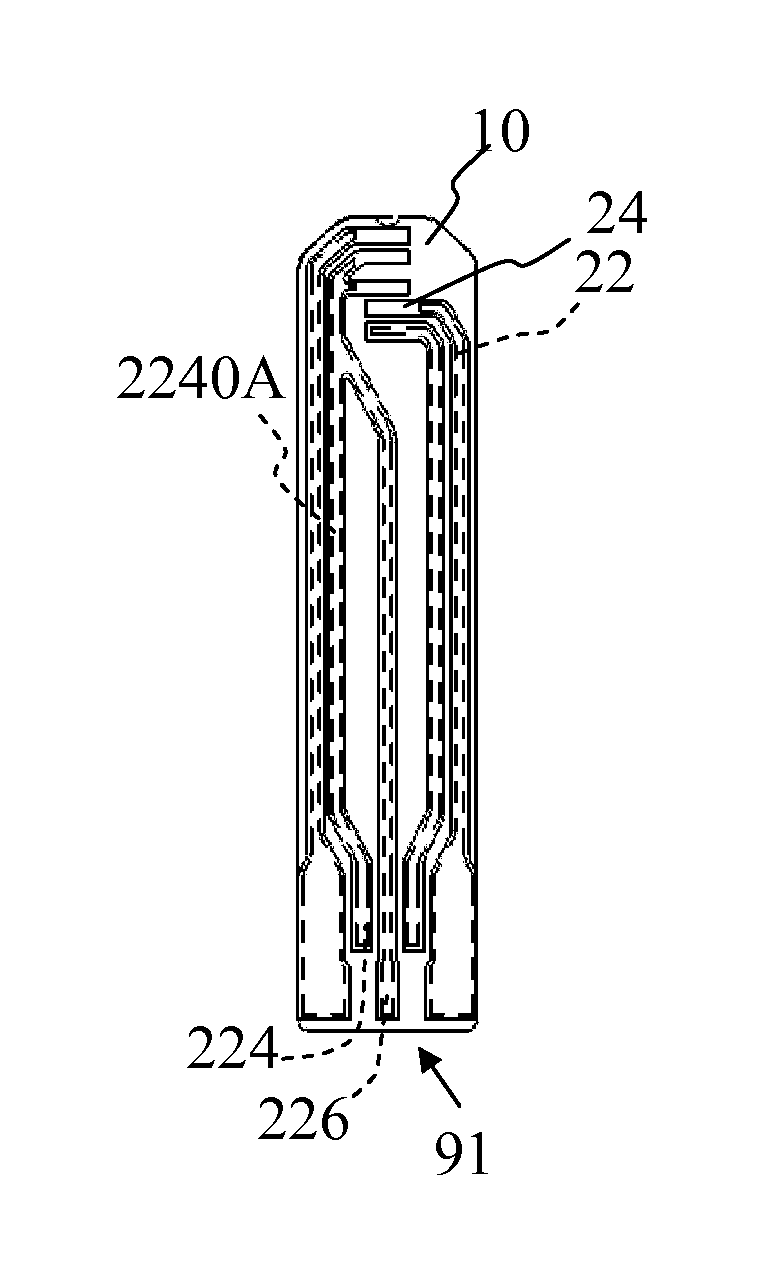

Electrochemical biosensor strip and method for identifying a corresponding biosensing device by said strip

ActiveUS8608920B2Eliminate stepsAvoid inaccurate resultsImmobilised enzymesBioreactor/fermenter combinationsElectrochemical biosensorEngineering

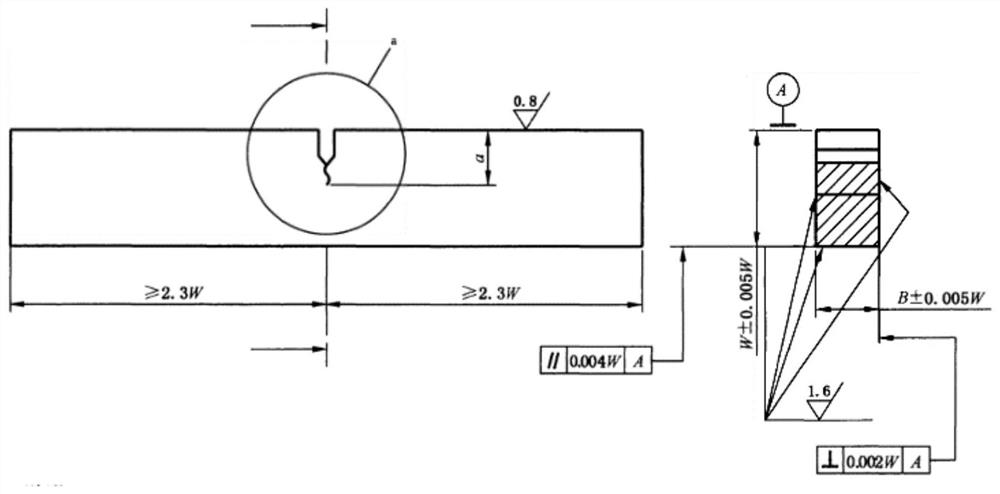

The present invention relates to an electrochemical biosensor strip comprising a base which has a front side and a back side, an electrode system on the front side of said base, a code-recognition element on one end of the back side of said base, a cover which is located on said electrode system, and a reaction area which is in touch with said electrode system for a reaction to take place. By forms of said code-recognition element provided in the present invention, a biosensing device will automatically choose a specific set of calibration code corresponding to a particular batch of the electrochemical biosensor strip while coupling to the strip. Hence, the present invention eliminates the calibration step carried out by users and simplifies the measuring procedure, avoiding the inaccurate results due to the omission or improper operation of the calibration step by users. The present invention further relates to a method for identifying a corresponding biosensing device by using a ratio of lengths of each length-changeable area of the strip.

Owner:TAIDOC TECH CORP

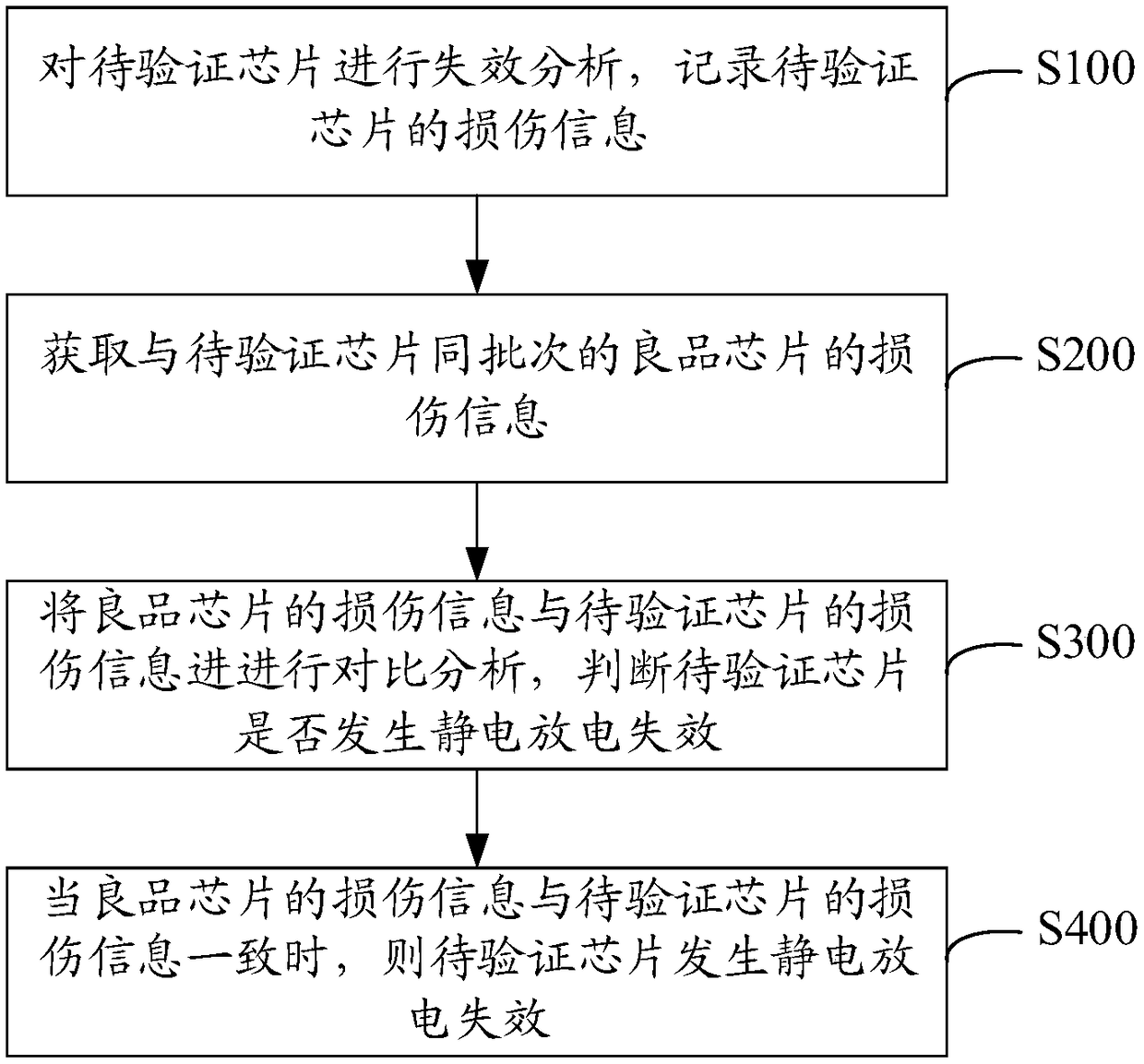

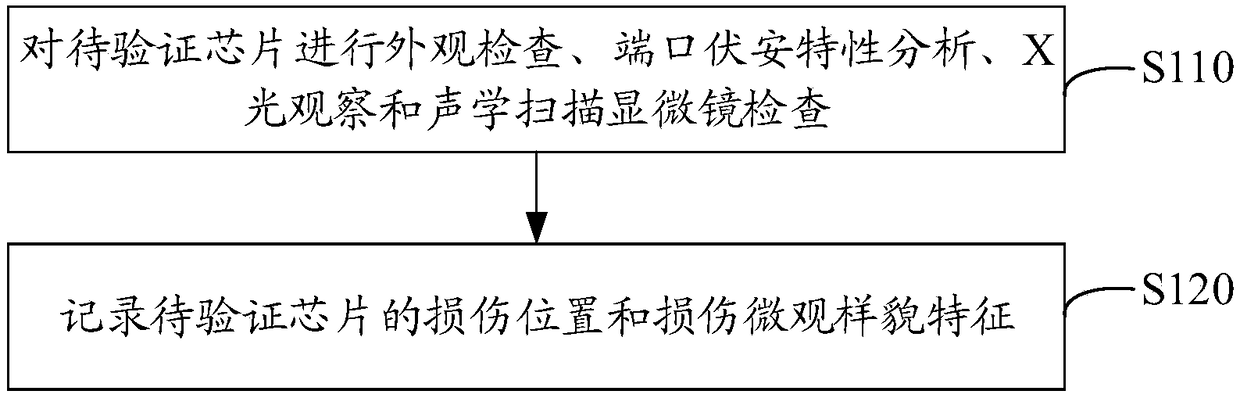

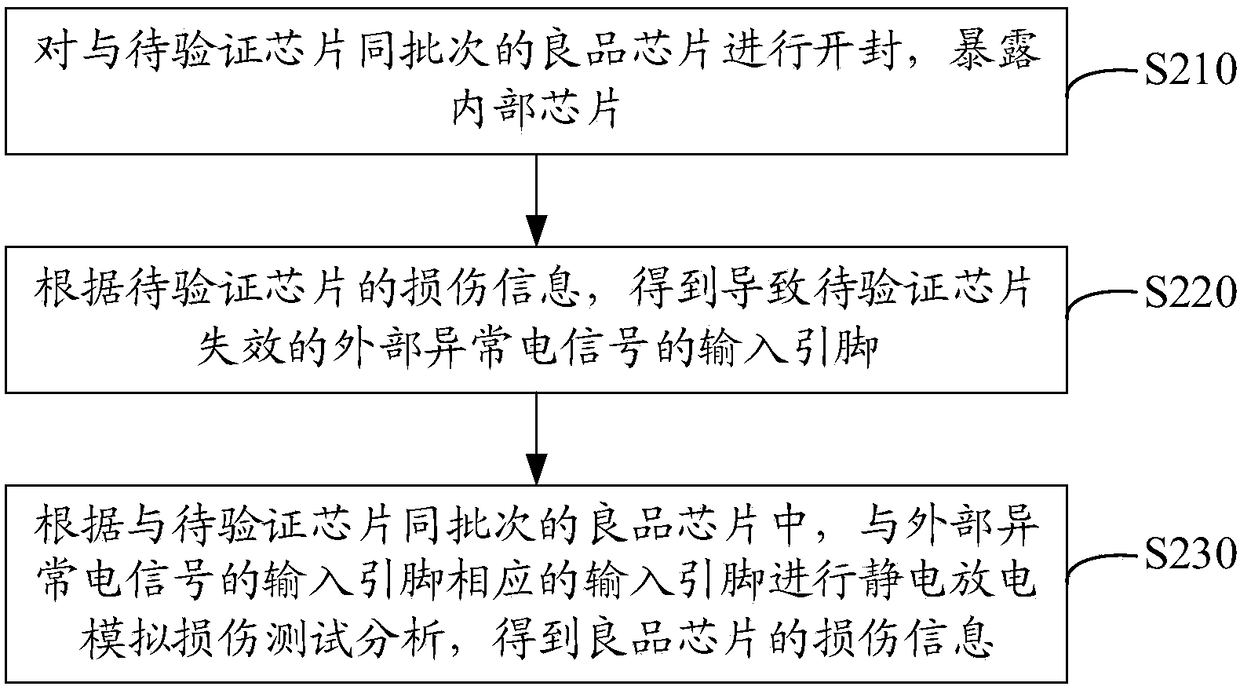

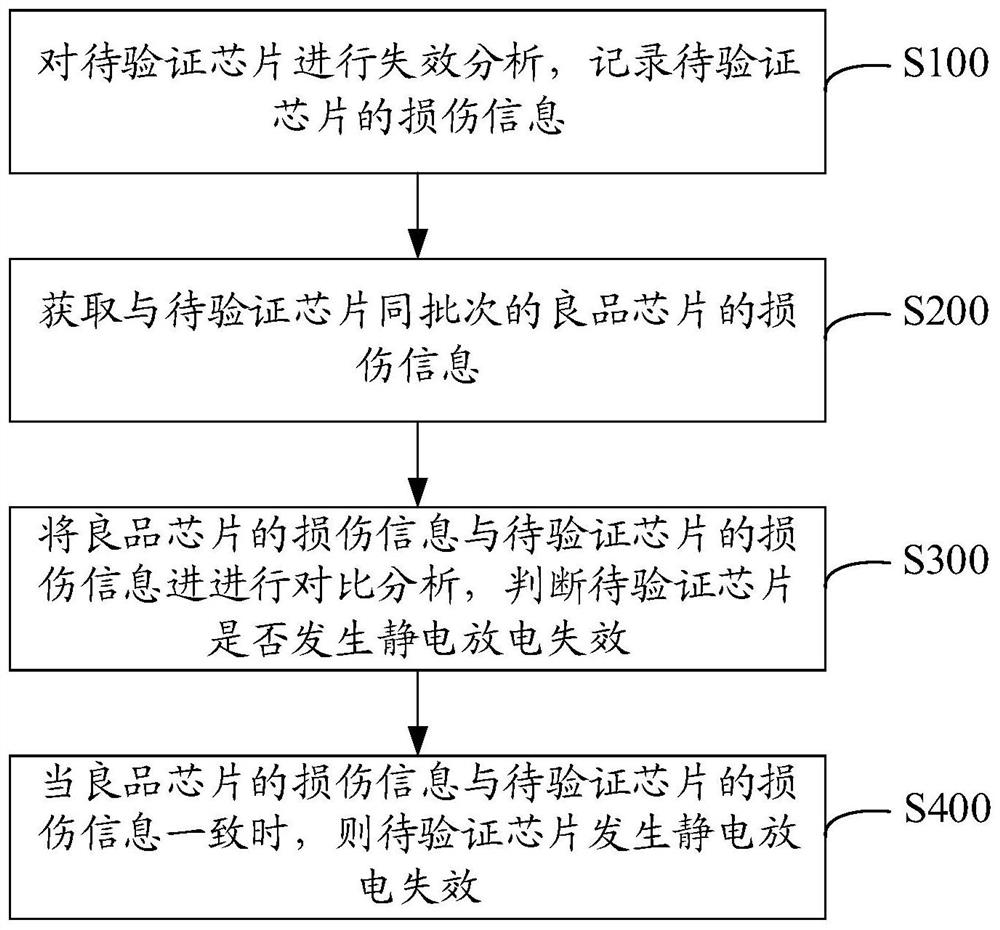

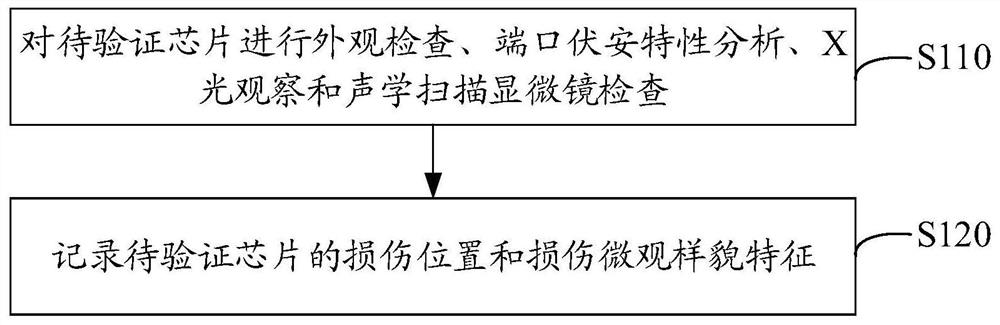

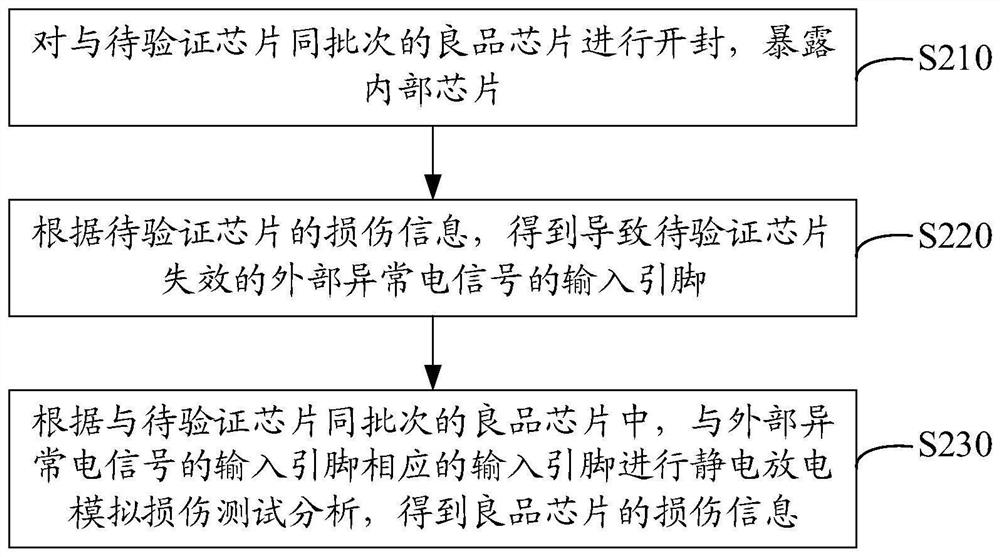

Verification method for electrostatic discharge failure

ActiveCN108398631AAvoid inaccurate resultsImprove reliabilityElectronic circuit testingValidation methodsTest analysis

The invention relates to a verification method for an electrostatic discharge failure. The method comprises the steps that a chip to be verified is subjected to failure analysis, and damage information of the chip to be verified is recorded; damage information of a good-quality chip in the same batch of the chip to be verified is acquired, wherein the damage information of the good-quality chip isobtained after the good-quality chip is subjected to electrostatic discharge simulation damage test analysis; the damage information of the good-quality chip and the damage information of the chip tobe verified are compared and analyzed, and whether or not the electrostatic discharge failure happens to the chip to be verified is judged; when the damage information of the good-quality chip is identical to that of the chip to be verified, it is determined that the electrostatic discharge failure happens to the chip to be verified. According to the verification method for the electrostatic discharge failure, before electrostatic discharge failure analysis, the chip with a suspected electrostatic discharge failure is subjected to electrostatic discharge failure verification, the situation isavoided that an inaccurate result is obtained by directly adopting electrostatic discharge failure analysis, and the reliability of electrostatic discharge failure analysis is improved.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST +1

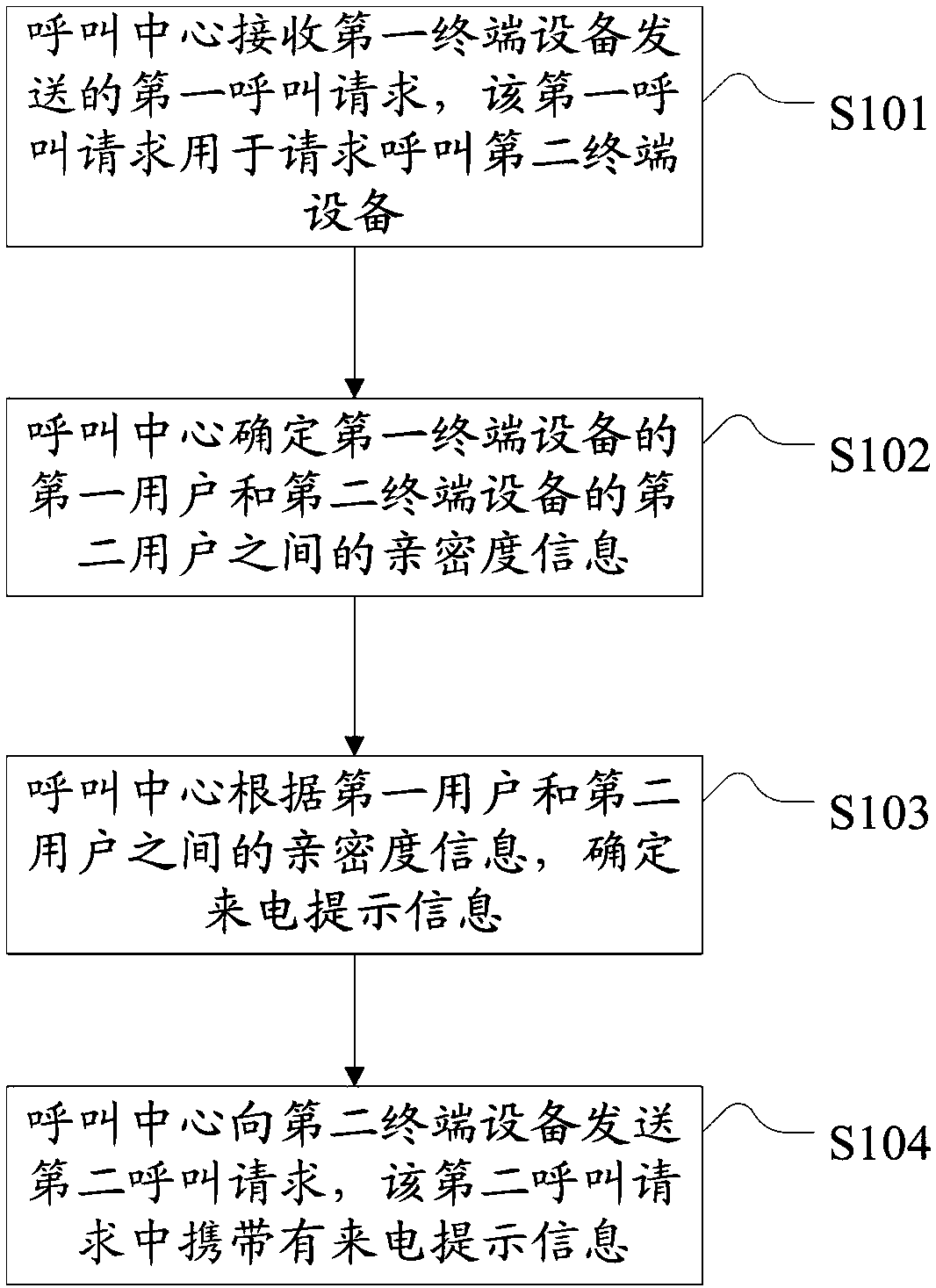

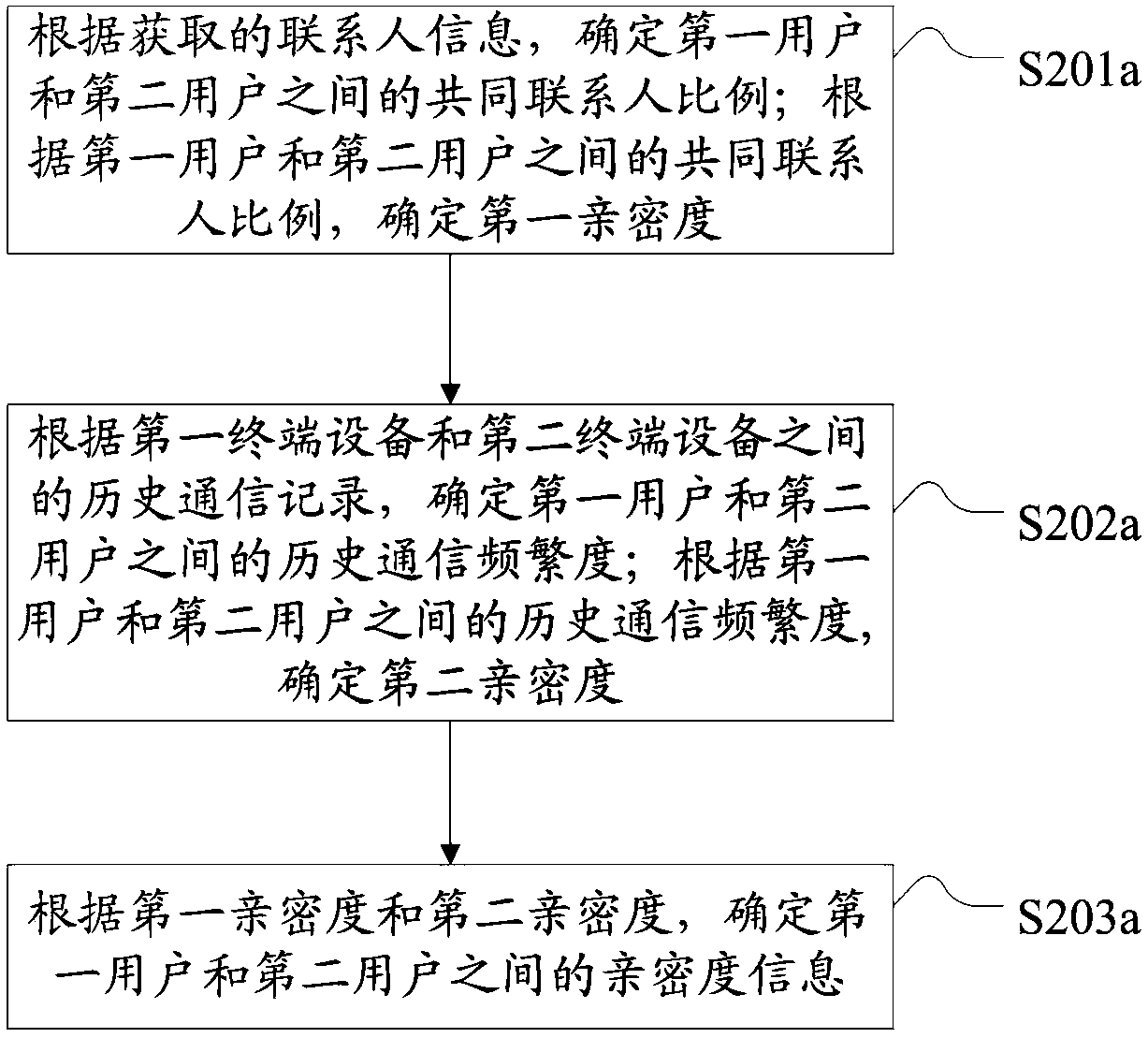

Incoming call reminding method and device

InactiveCN107707775AAvoid inaccurate resultsLow costSpecial service for subscribersTerminal equipmentCall centre

The application relates to the technical field of the mobile communication, and in particular relates to an incoming call reminding method and device. A problem that the processing on the strange number is inaccurate and high in running cost in the prior art is solved. The method provided by the embodiment of the application comprises the following steps: receiving a call request sent by first terminal equipment and used for calling second terminal equipment by a call center; determining the intimacy information between a first user of the first terminal equipment and a second user of the second terminal equipment; determining the incoming call reminding information according to the intimacy information; and then sending the call request carrying the incoming call reminding information tothe second terminal equipment, wherein the reminding information to the second terminal equipment is determined according to the intimacy between the first user and the second user. Therefore, the obtained result is hardly affected by other irrelevant user, an operation of establishing a marking number base by collecting a large number of user marking behaviors is unnecessary, the processing on the strange number is high in accuracy and low in running cost.

Owner:CHINA MOBILE COMM LTD RES INST +1

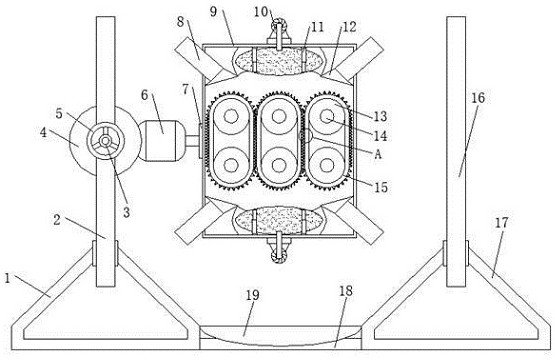

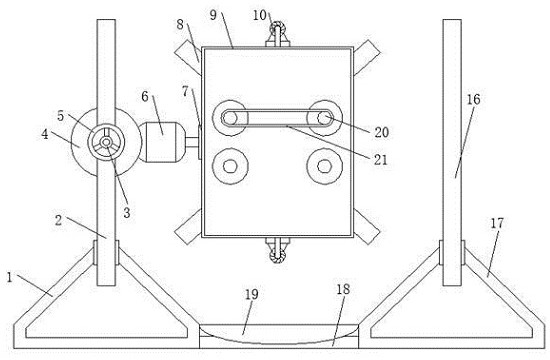

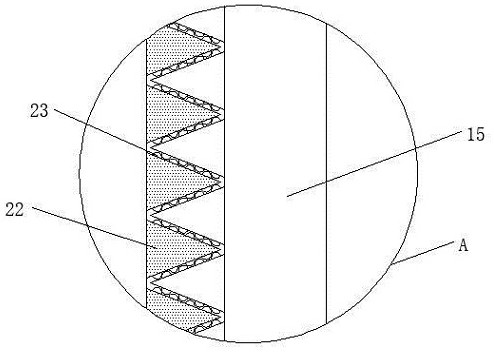

Automatic detection device for feed quality

ActiveCN112362431APlay a cutting effectAvoid inaccurate resultsChemical analysis using combustionPreparing sample for investigationAgricultural engineeringStructural engineering

The invention discloses an automatic detection device for feed quality, and provides the following scheme aiming at the problems that the detection capability is perfect, but the crushing degree of the taken feed is not enough, so that the result is not fine enough: the automatic detection device comprises a box body, two first brackets and two second brackets, and the tops of the two first brackets are fixedly connected with first straight plates; an adjusting turnover mechanism is arranged at the position, close to the middle, of the inner wall of the opposite side of the first straight plate, the adjusting turnover mechanism is connected with the box body, a plurality of connecting shafts are rotatably inserted into the box body, the connecting shafts are arranged in parallel in two rows in the middle of the box body, and the upper connecting shaft and the lower connecting shaft form a set and are three sets in total. The circumferential outer wall of each connecting shaft is sleeved with a transmission roller. Feed is cut and crushed through the densely-distributed triangular cutting blocks, the feed can reach the lower area only through layer-by-layer triangular cutting blocks, and therefore the feed needs to be comprehensively crushed through the triangular cutting blocks, and the feed is fully crushed.

Owner:北京德元顺生物科技有限公司

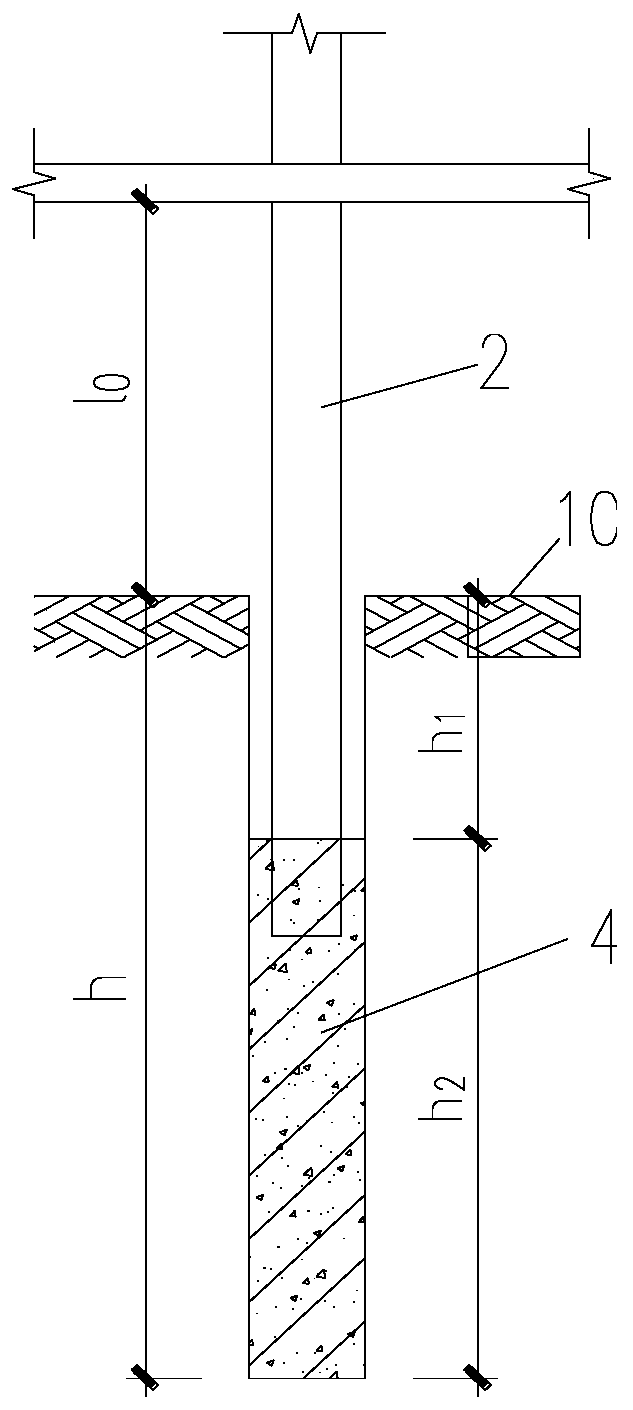

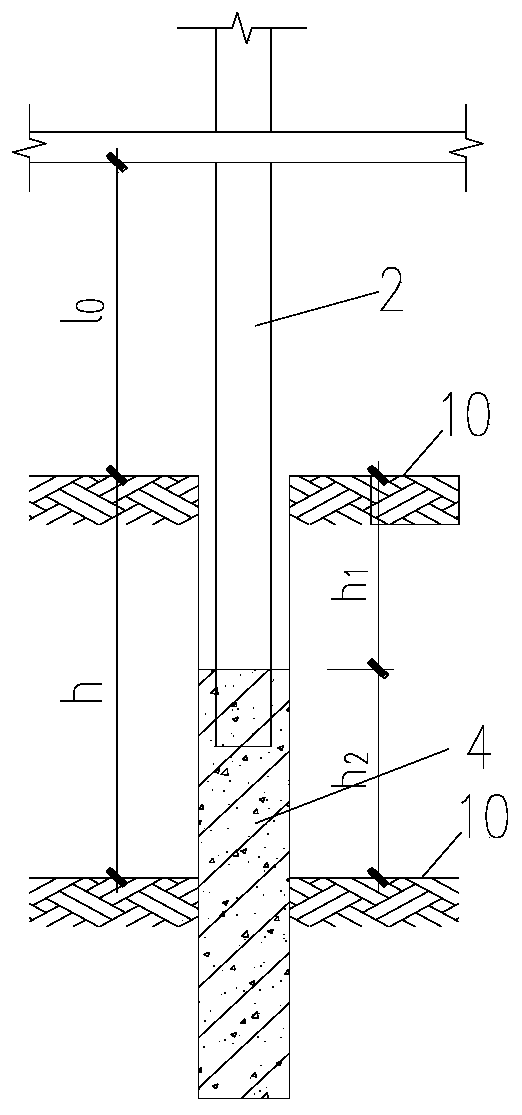

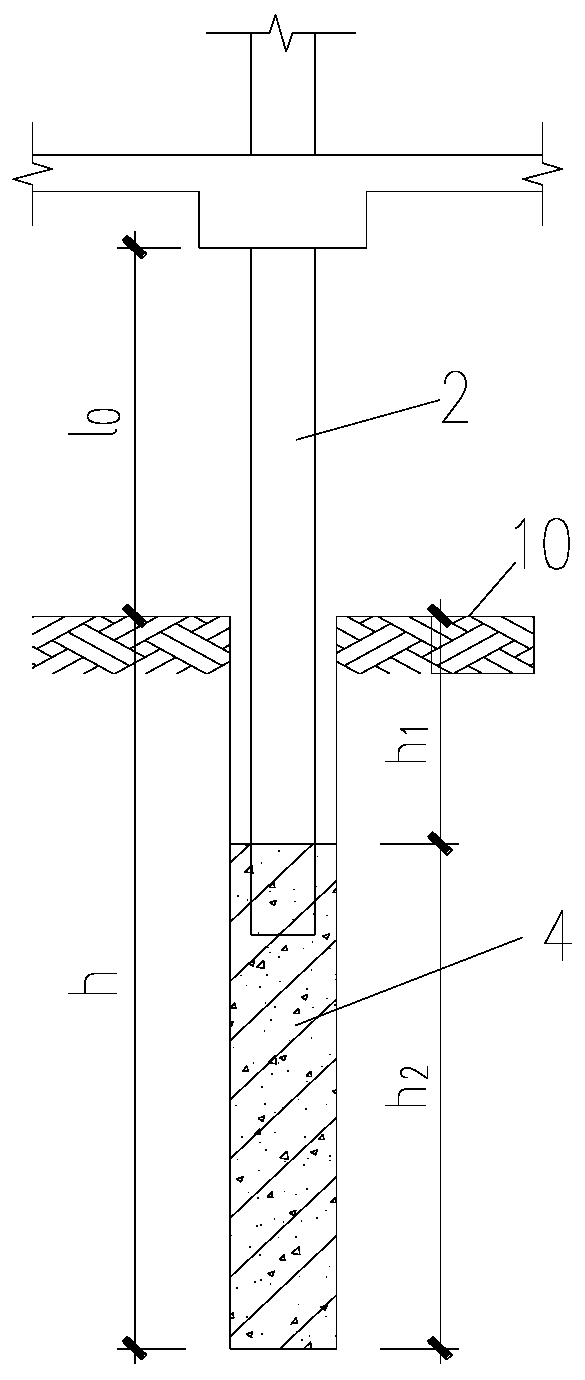

Vertical support column bearing capacity test simulation device in reverse construction environment

ActiveCN111501861ARealize simulationScientific carrying capacity test systemFoundation testingControl cellStrain gauge

The invention provides a vertical support column bearing capacity test simulation device in reverse construction environment. The device comprises a box body, a steel tube test piece, bedrock, an actual pile, soil layers, a pressure applying assembly, a control unit, and a test unit, wherein the bedrock whose middle part is provided with a pile hole is placed into the box body, the steel tube testpiece filled with concrete is coaxially inserted into the actual pile arranged in the pile hole, a plurality of layers of soil layers are compacted in sequence above the bedrock in the height direction of the box body, a medium material can fill the space between the inner side wall of the soil layer and the surface of the steel tube test piece, the pressure applying assembly is used for applyingpressure to the upper end of the steel tube test piece, and the control unit is in signal connection with a plurality of strain gauges and a plurality of displacement meters D arranged on the steel tube test piece and connected with the controlled end of the pressure applying assembly. According to the device, a pile is the actual pile, and a steel tube filled with the concrete is used as a column. According to the device, the influence, generated when different gaps are adopted between the pile and the column for backfill materials, on the constraint effect of the support column is researched through the test, so as to verify the rationality of the vertical support column slenderness ratio calculation formula.

Owner:ANHUI INST OF BUILDING RES & DESIGN

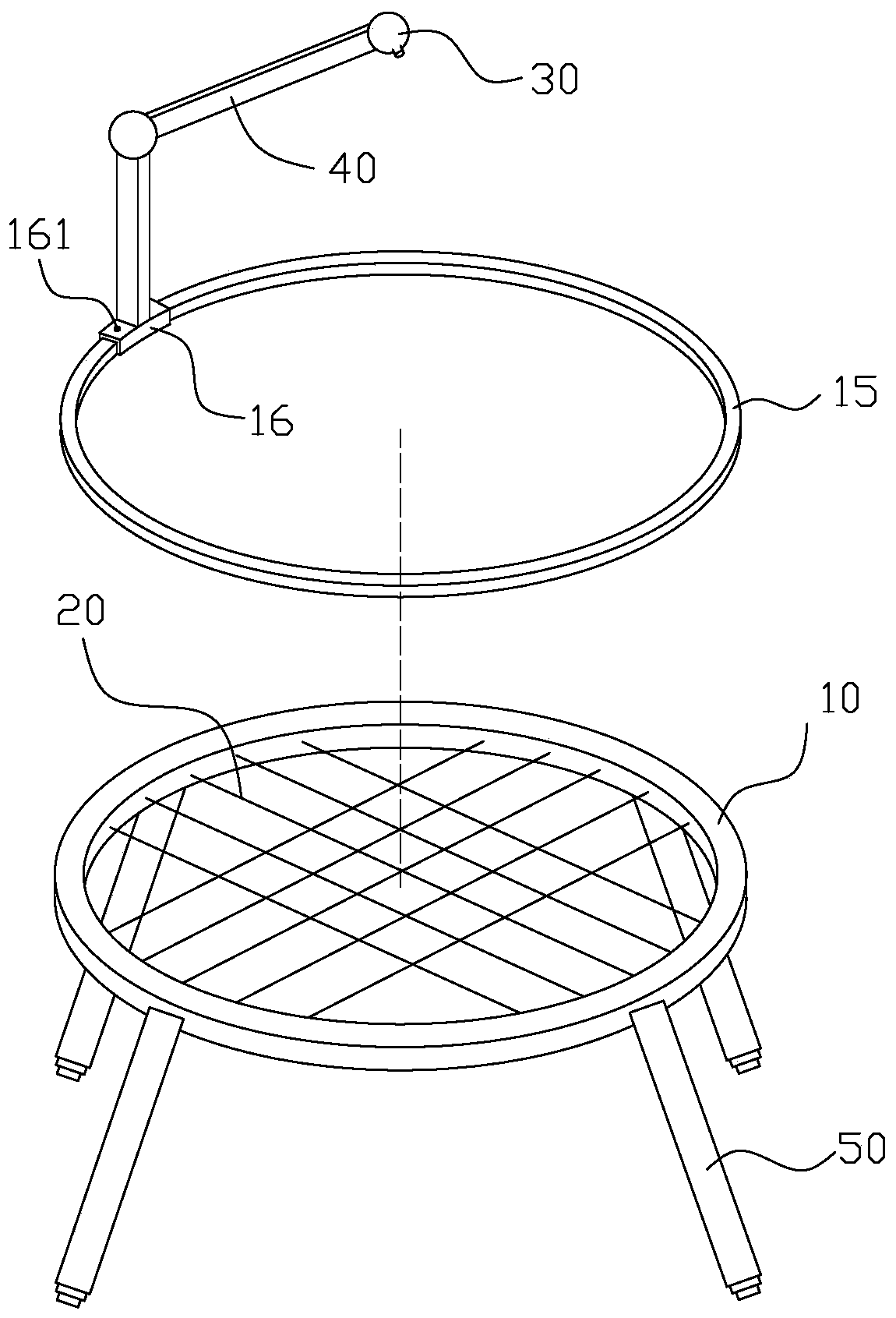

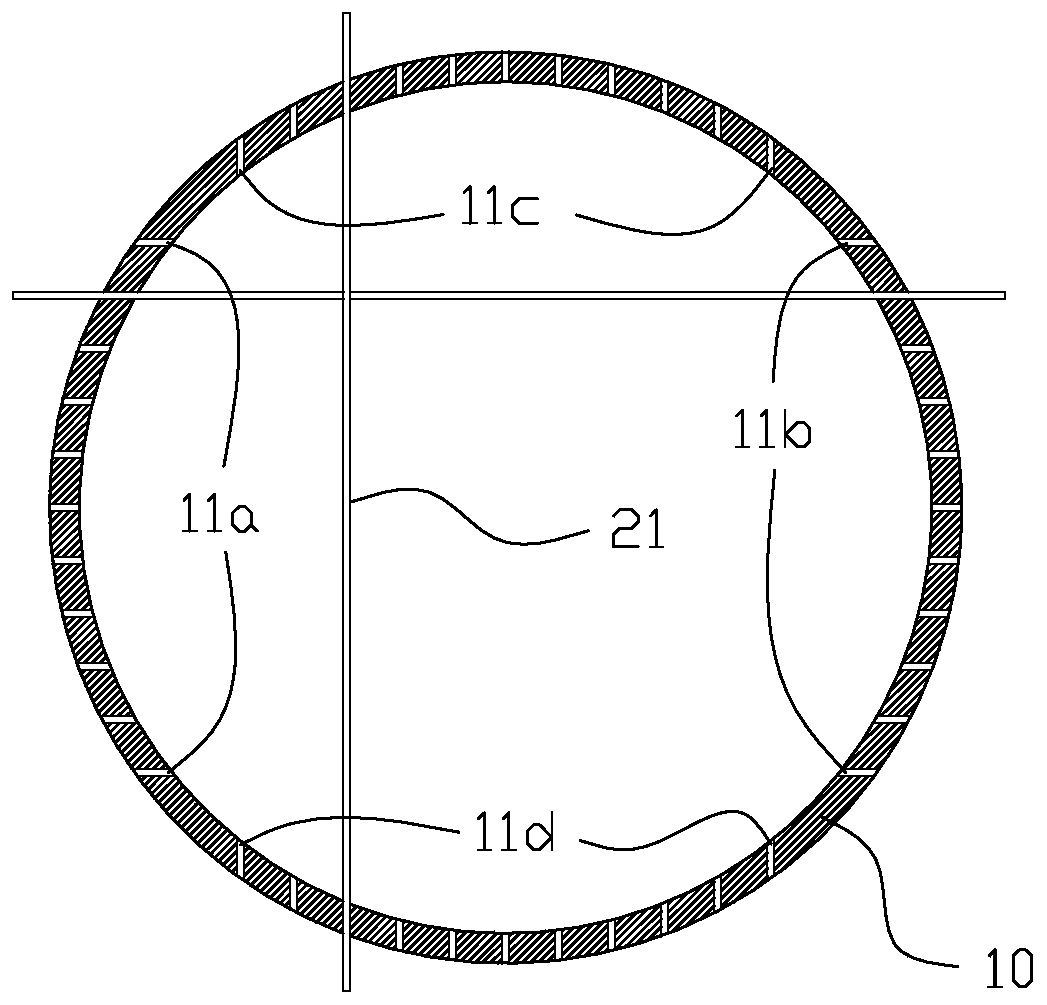

Wheat scab detection method based on multi-angle field high-definition imaging

ActiveCN110736750AEasy to handleAvoid inaccurate resultsOptically investigating flaws/contaminationDiseaseComputer graphics (images)

The invention particularly relates to a wheat scab detection method based on multi-angle field high-definition imaging. The method comprises the following steps: (A), arranging a loosening frame in ato-be-detected area of a field, and enabling wheat ears to pass through grid holes of the loosening frame; (B), starting a shooting unit, and collecting M multi-angle wheat ear images; (C), processingthe M wheat ear images, identifying wheat ears in the images and grids corresponding to the wheat ears to obtain a wheat ear area and a disease infection area of each wheat ear in each wheat ear image so as to calculate wheat ear disease severity; and (D), calculating an nth wheat ear disease severity mean value. With multi-angle shooting, a phenomenon of inaccurate results caused by shielding ofwheat ears at a certain angle can be avoided; for matching of same wheat ears in multi-angle pictures, the wheat ears are segmented by the loosening frame, so that the high accuracy and the processing speed of subsequent wheat ear matching are guaranteed. Meanwhile, the wheat ears become tidy and the shot picture processing effect is optimized.

Owner:ANHUI UNIVERSITY

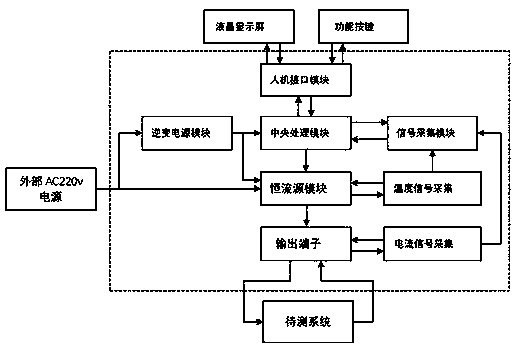

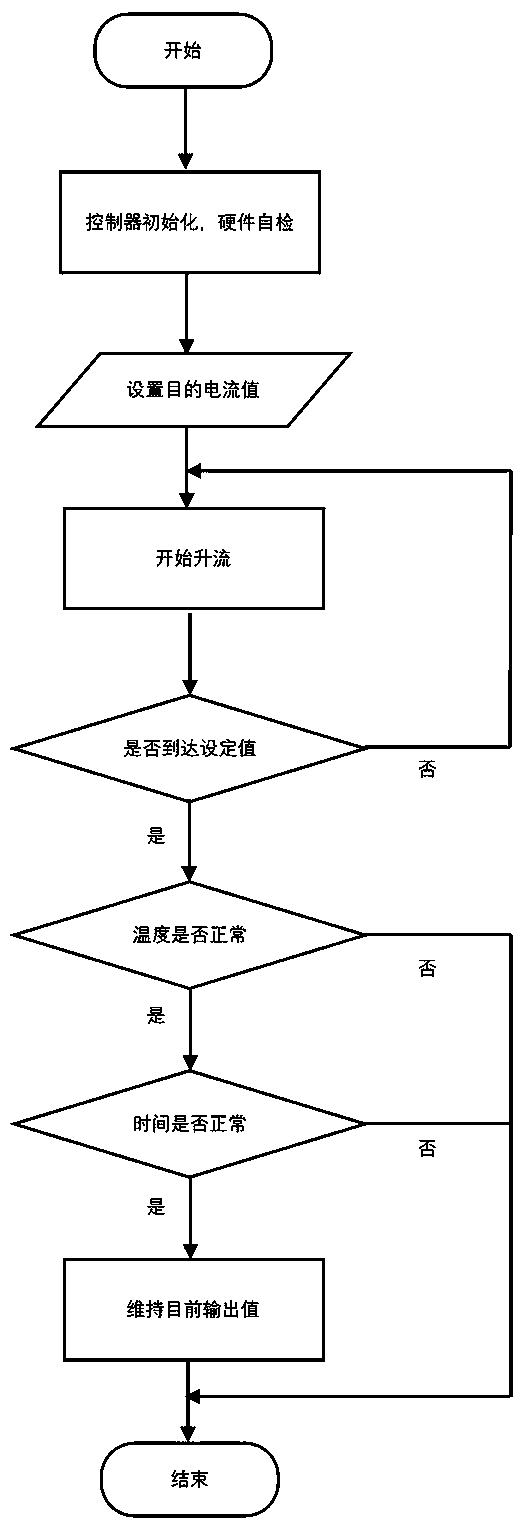

Portable differential circuit calibrator and calibration method

PendingCN110927508AGuaranteed uptimeAccurate operating parametersElectrical testingEngineeringControl theory

The invention discloses a portable differential circuit calibrator. A differential circuit is provided with two connecting terminals used for being connected with a current transformer. The calibratorcomprises a central processing module. The central processing module is electrically connected with a constant current source module, a man-machine interface module, a signal acquisition module and apower supply mechanism; and the constant current source module is connected with the connecting terminal through two output terminals, the constant current source module is electrically connected with the power supply mechanism, the man-machine interface module is electrically connected with a man-machine interaction mechanism, and the signal acquisition module comprises a current signal collector electrically connected with the output terminal and a temperature signal collector electrically connected with the constant current source module. According to the portable differential circuit calibrator and the calibration method provided by the invention, the calibration result accuracy and the calibration process efficiency are higher.

Owner:THE 1ST ENG CO LTD OF CHINA RAILWAY CONSTR ELECTRIFICATION BUREAU GRP

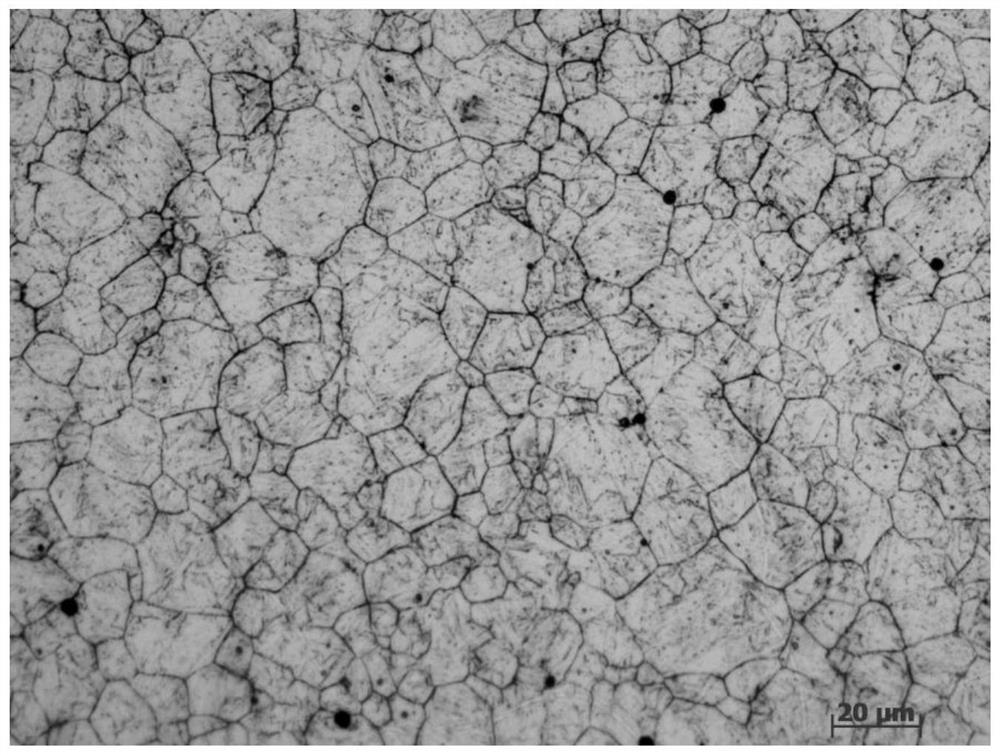

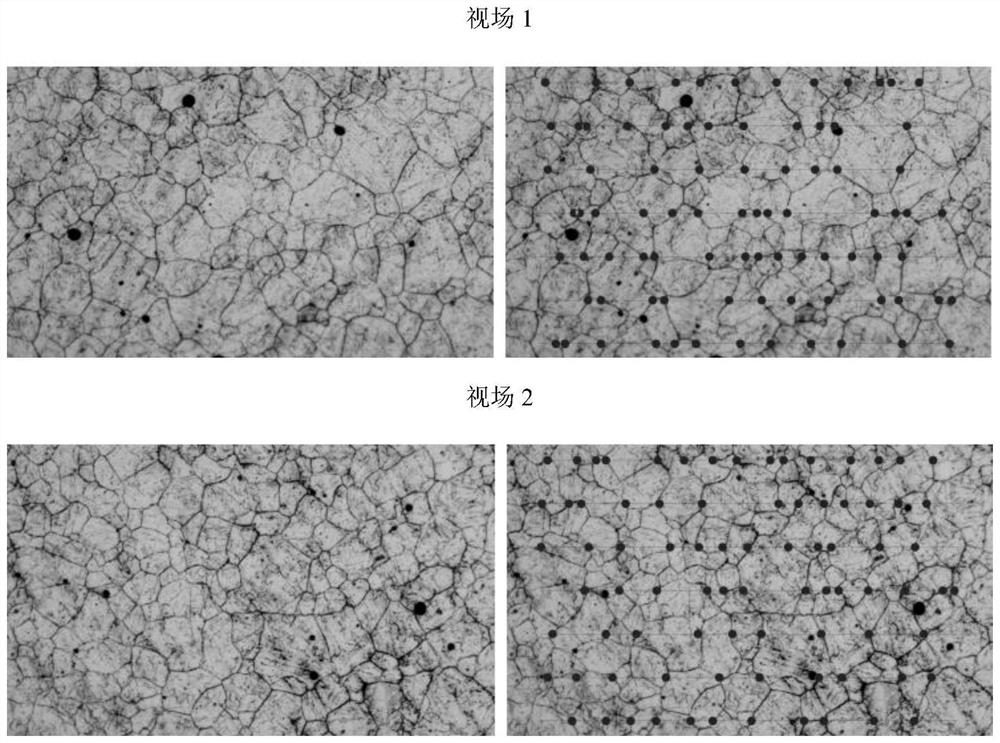

Corrosion method for original austenite grain size of tempered troostite and martensite structures

ActiveCN113063707AAvoid inaccurate resultsCorrosion priorityPreparing sample for investigationParticle size analysisAustenite grainAlcohol

The invention belongs to the technical field of original austenite grain size testing, and provides a corrosion method for the original austenite grain size of tempered troostite and martensite structures and aims at the problem that a grain size result tested by an oxidation method is not accurate. The corrosion method comprises the following operation steps that: the original austenite of the tempered troostite or martensite structures is taken as a sample, grinding and polishing treatment is carried out on the sample after the sample is pretreated, the sample is put into a corrosive agent to be corroded, and after the surface of the sample becomes black, the sample is cleaned with absolute ethyl alcohol and blow-dried, and the corrosive agent is composed of a saturated picric acid aqueous solution, sodium dodecyl benzene sulfonate and a saturated ferric trichloride aqueous solution. By utilizing the corrosion method, the corroded grain boundary of the sample is clear, the original austenite grain size of the tempered martensite and tempered troostite structures can be directly tested, and rating is accurate.

Owner:ZHEJIANG MEILI HIGH TECH

Manufacturing process multivariate quality diagnosis classifier based on statistical method

InactiveCN108037744AStrict process capability coefficient conditionsJudgment status is accurateCharacter and pattern recognitionTotal factory controlSupport vector machineOriginal data

Provided is a manufacturing process multivariate quality diagnosis classifier based on a statistical method. The original data of the quality characteristics in a manufacturing process is collected and preprocessed. A process analysis is made of the multivariate quality characteristics of key procedures. The stability and whether there is an abnormal phenomenon are determined according to the datarecorded in a control chart. The process anomaly source is found through a statistical method. In order to make the classicization result more accurate, class mean, chi-square value, the weight ratiobetween class mean and chi-square value, and a mean distance stability criterion are introduced. The process capability coefficient condition is strict. The determined state is accurate. The algorithm complexity is low. The processing is fast. Multivariate quality, a misjudgment factor and a principal component factor are integrated. The classifier is of higher applicability. Parameter processingis standard. Data processing is perfect. The misjudgment probability is reduced. The problems of data bias and unit non-uniformity are solved. The manufacturing process multivariate quality diagnosisclassifier is more accurate than a support vector machine. An anomaly diagnosis technology can be realized.

Owner:SICHUAN YONGLIAN INFORMATION TECH CO LTD

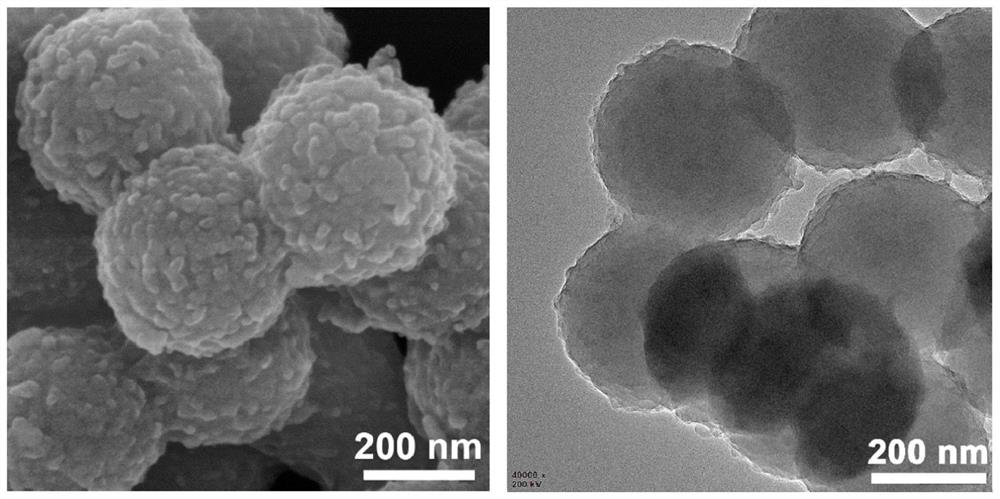

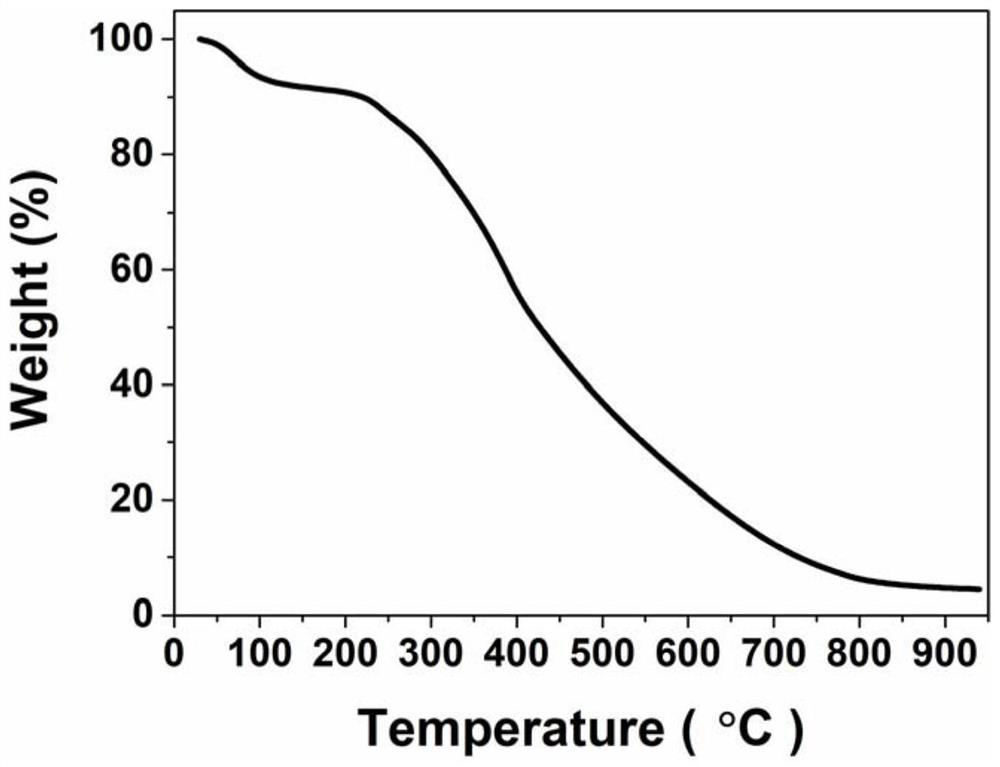

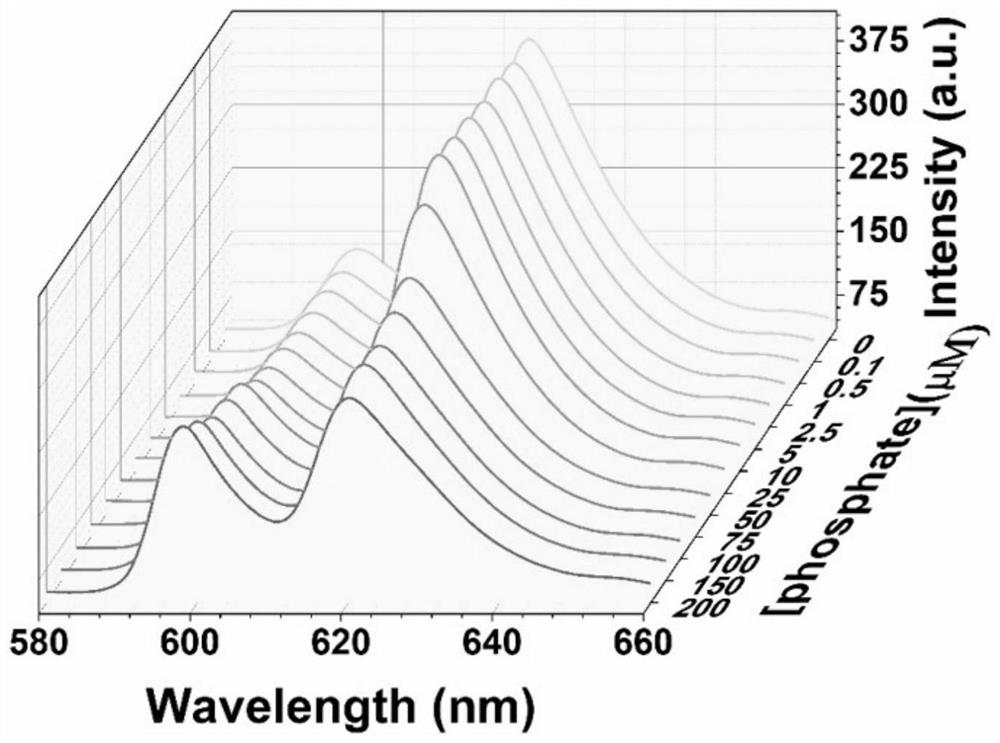

Cyclodextrin-europium/lanthanum molybdate hybrid microsphere, preparation method thereof and application of cyclodextrin-europium/lanthanum molybdate hybrid microsphere in fluorescence detection of phosphorus-containing compound

ActiveCN113583152AEasy to prepareSynthetic conditions are mildGeneral water supply conservationFluorescence/phosphorescencePhosphate ionFluorescence

The invention relates to a cyclodextrin-europium / lanthanum molybdate hybrid microsphere, a preparation method thereof and application of the cyclodextrin-europium / lanthanum molybdate hybrid microsphere in fluorescence detection of a phosphorus-containing compound. The preparation method comprises the steps of firstly, preparing a mixed solution containing a molybdenum source and aldehyde cyclodextrin; adding a cross-linking agent and a cosolvent into the mixed solution, and stirring for reaction to obtain a molybdenum modified aldehyde cyclodextrin suspension; and adding a lanthanum source and a europium source into the molybdenum modified aldehyde cyclodextrin suspension, continuously stirring for reaction, and purifying to obtain the cyclodextrin-europium molybdate / lanthanum hybrid microsphere. The prepared hybrid microsphere can be used as a fluorescence detector for qualitative or quantitative detection of phosphate ions, nitrobenzene phosphate or dinitrobenzene phosphate. Compared with the prior art, the advantages of simplicity in preparation, stable signal, high sensitivity, high selectivity, high interference resistance and the like are achieved, and meanwhile, the inorganic phosphate ions and the nitrobenzene phosphate are distinguished and detected through different fluorescent signal response modes.

Owner:TONGJI UNIV

Non-invasive prenatal detection device

PendingCN112712853ASmall fluctuationHelps GG correctionCharacter and pattern recognitionSequence analysisSmall sampleMedicine

The invention relates to the technical field of bioinformatics, and particularly discloses a non-invasive prenatal detection device. The device comprises a detection module, a data quality control and preprocessing module, a data correction and processing module and a judgment module; a dynamic database is constructed through the data correction and processing module to correct deviations caused by different chromosome baselines again, and subsequent PCA noise reduction, parent source CNV recognition screening, segmentation of a window Z value through a CBS algorithm and other modes are matched, so that influences caused by batch deviations are effectively reduced, and false cathodes or false anodes caused by the batch deviations are avoided; application of to-be-tested batch samples as a reference set is avoided, so that inaccurate results caused by small sample size are avoided; the number of samples in a gray area is reduced, the detection cost is reduced, and the detection period is shortened.

Owner:BEIJING USCI MEDICAL LAB CO LTD

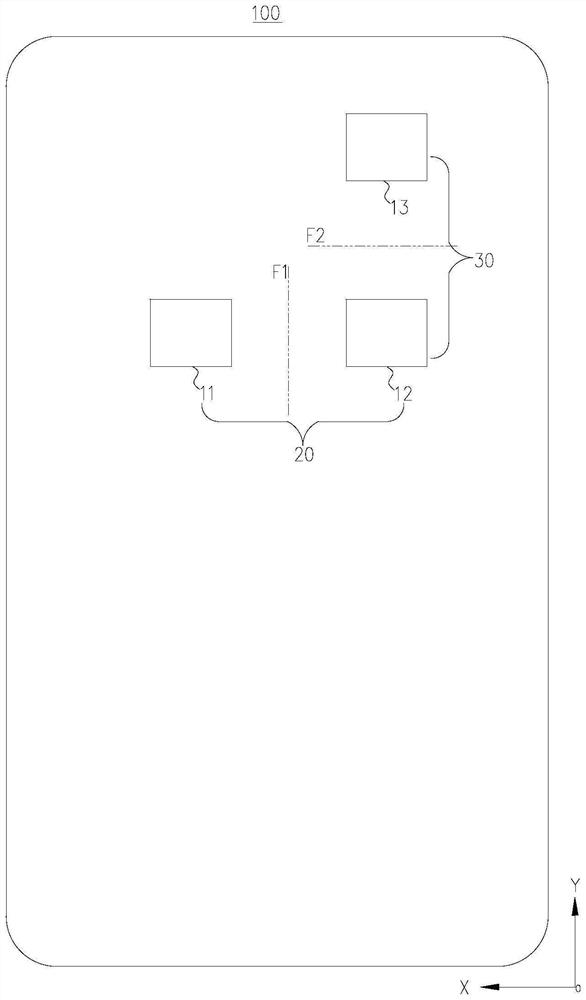

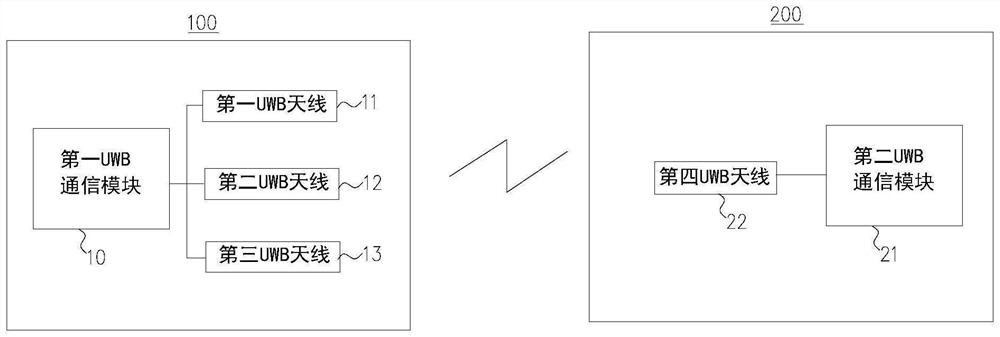

Arrival angle determination method and related device

PendingCN114563758AImprove accuracyAvoid inaccurate resultsRadio wave direction/deviation determination systemsHigh level techniquesEngineeringReal-time computing

The invention provides an angle of arrival determination method and a related device. The method comprises the following steps: acquiring a first phase difference of an antenna signal sent by a to-be-tested device in a first direction; a first arrival angle of the antenna signal in a second direction is determined, and the first direction intersects with the second direction; determining a second angle of arrival of the antenna signal in the first direction according to the first phase difference and the first angle of arrival; and according to the first angle of arrival and the second angle of arrival, determining a target angle of arrival at which the electronic device receives the antenna signal. According to the arrival angle determination method and the related device provided by the invention, the accuracy of arrival angle measurement of the antenna signal can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Manufacturing process multivariate quality diagnostic classifier based on improved information entropy

InactiveCN108090506AStrict process capability coefficient conditionsJudgment status is accurateCharacter and pattern recognitionSupport vector machineOriginal data

The invention provides a manufacturing process multivariate quality diagnostic classifier based on improved information entropy. The manufacturing process multivariate quality diagnostic classifier isused for collecting original data of quality characteristics in the manufacturing process, carrying out data preprocessing, applying a hybrid algorithms to perform process analysis on multivariate quality characteristics of key processes, discriminating stability and whether an abnormal phenomenon occurs or not according to data recorded in a control chart, adopting an information entropy methodto find out a process abnormity source, and introducing an adjustment factor, a chi-square value, a weight ratio between the two and an Euclidean distance stability discrimination rule so that the classification result is enabled to be more accurate. The manufacturing process multivariate quality diagnostic classifier is strict in process capability coefficient conditions, accurate in determination state, low in algorithm complexity and fast in processing time, combines multivariate quality, misjudgement factors and major constituent factors, is higher in applicability, standard in parameter processing and complete in data processing, reduces the misjudgement probability, solves the problems of data offset and unit non-uniformity, has higher accuracy degree than that of a support vector machine, and can realize the abnormity diagnosis technology.

Owner:SICHUAN YONGLIAN INFORMATION TECH CO LTD

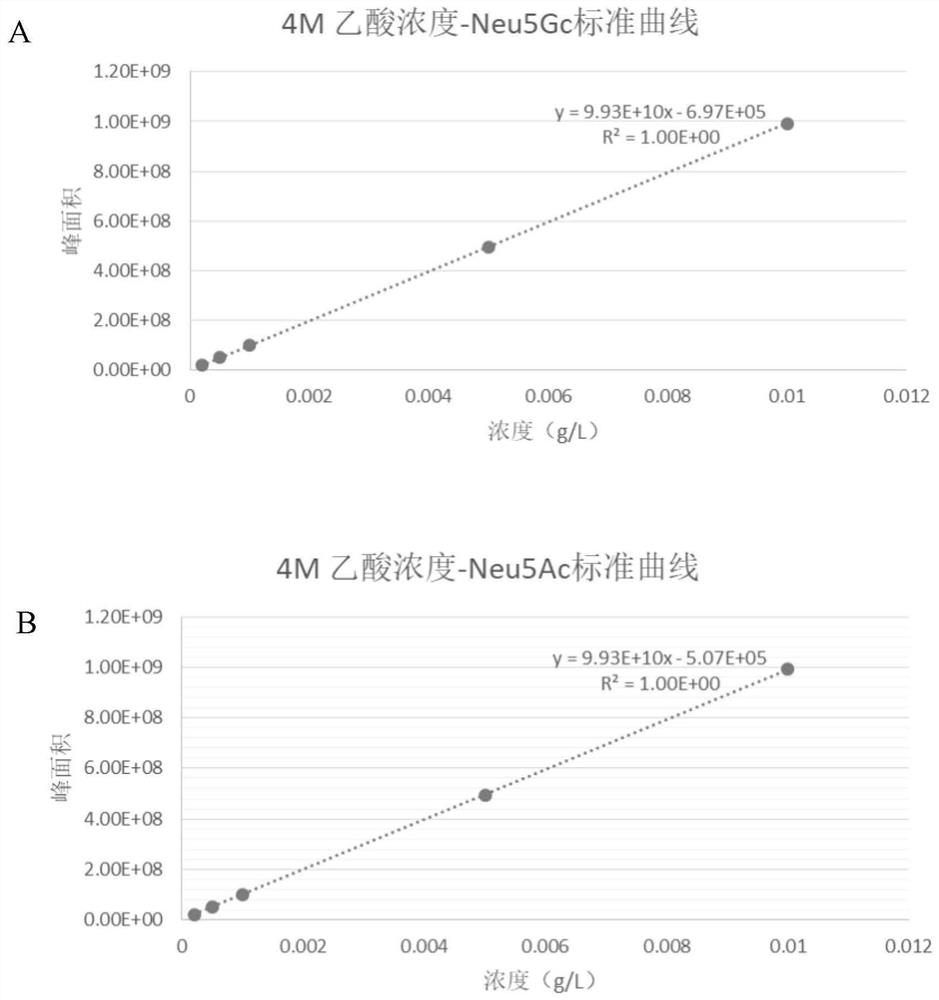

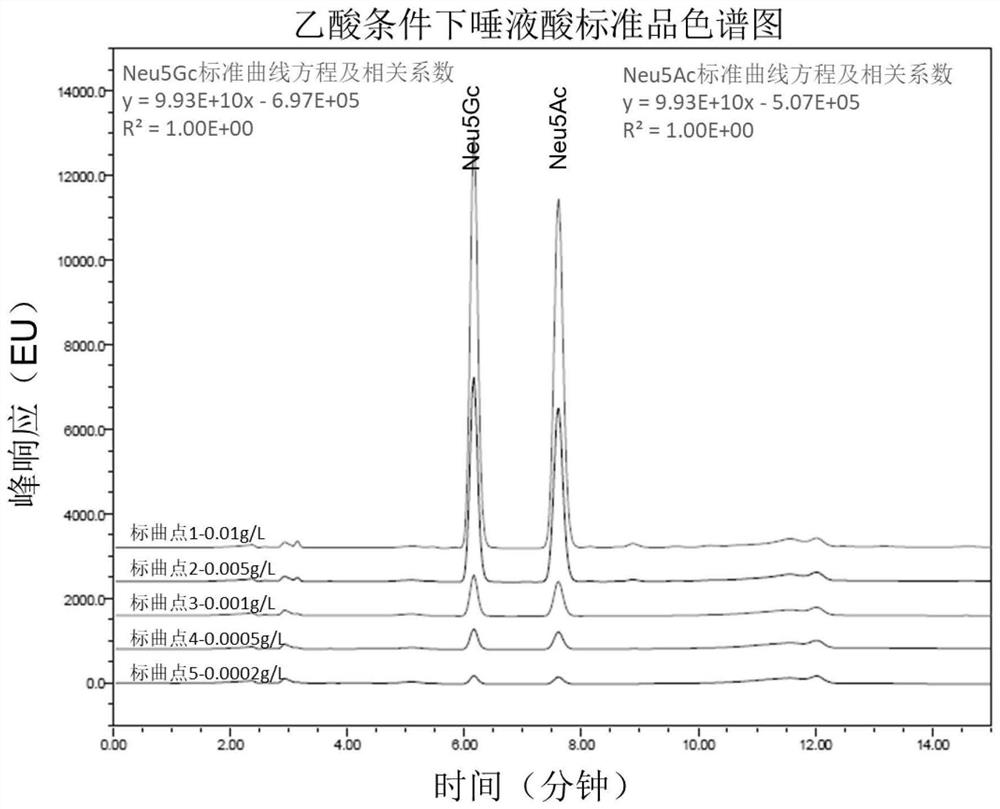

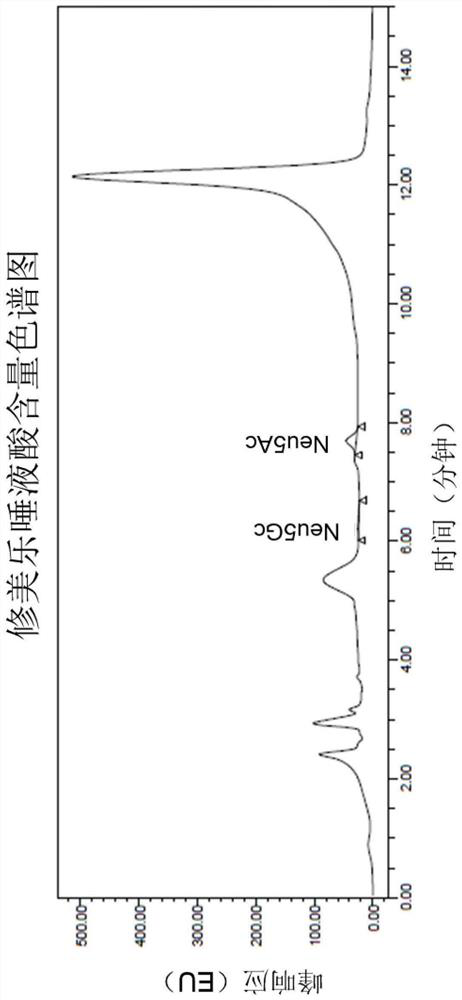

High performance liquid chromatography for analyzing sialic acid content in sample

PendingCN114460186AGood linear relationshipSolve the phenomenon of insufficient acid hydrolysis or affect the derivatization reactionComponent separationSpectrophotometrySialic acid

The invention discloses a high performance liquid chromatography method for analyzing the content of sialic acid in a sample, and the method comprises the following steps: mixing acetic acid with a protein sample to obtain a mixed solution, so that the sialic acid in the protein sample is released. The invention solves the problems of low specificity of spectrophotometry, poor repeatability of thin-layer method, high cost of mass spectrometry and the like in the existing analysis technology, thereby providing a simple high performance liquid chromatography with high specificity and high accuracy for analyzing the content of sialic acid in different types of antibodies.

Owner:鼎康(武汉)生物医药有限公司

Electrostatic Discharge Failure Verification Method

ActiveCN108398631BAvoid inaccurate resultsImprove reliabilityElectronic circuit testingTest analysisFailure analysis

The invention relates to a verification method for an electrostatic discharge failure. The method comprises the steps that a chip to be verified is subjected to failure analysis, and damage information of the chip to be verified is recorded; damage information of a good-quality chip in the same batch of the chip to be verified is acquired, wherein the damage information of the good-quality chip isobtained after the good-quality chip is subjected to electrostatic discharge simulation damage test analysis; the damage information of the good-quality chip and the damage information of the chip tobe verified are compared and analyzed, and whether or not the electrostatic discharge failure happens to the chip to be verified is judged; when the damage information of the good-quality chip is identical to that of the chip to be verified, it is determined that the electrostatic discharge failure happens to the chip to be verified. According to the verification method for the electrostatic discharge failure, before electrostatic discharge failure analysis, the chip with a suspected electrostatic discharge failure is subjected to electrostatic discharge failure verification, the situation isavoided that an inaccurate result is obtained by directly adopting electrostatic discharge failure analysis, and the reliability of electrostatic discharge failure analysis is improved.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST +1

Rapid detection method of melamine liquid chromatography

PendingCN114878726AAvoid inaccurate resultsEfficient impurity contentComponent separationChemistryRaw milk

The invention discloses a rapid detection method of melamine liquid chromatography. The rapid detection method comprises a melamine extraction method and a liquid chromatography determination method. According to the detection method, an extraction method of the melamine is optimized, so that an accurate and reliable melamine liquid chromatography detection result meeting the national standard can be obtained without purification column and nitrogen blowing treatment in the detection process, the detection time of the melamine in the raw milk is remarkably shortened, the accuracy of the detection result is ensured, and the detection efficiency is improved. The method has positive effects on improving the production efficiency, shortening the production period and reducing the production cost, and is suitable for large-scale popularization and application.

Owner:SICHUAN NEW HOPE DAIRY

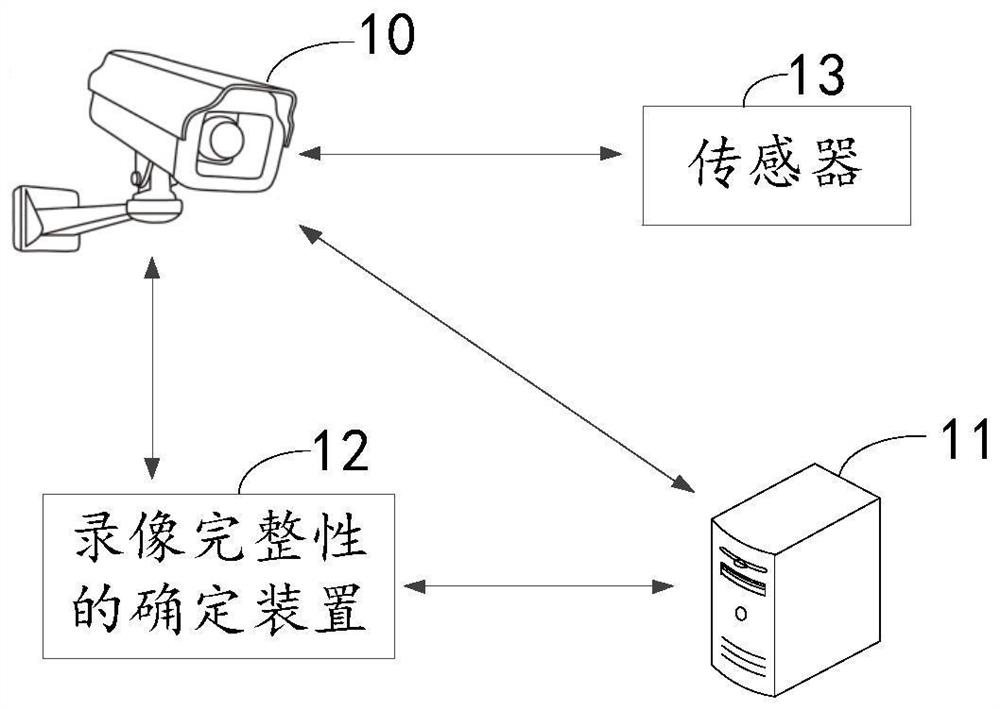

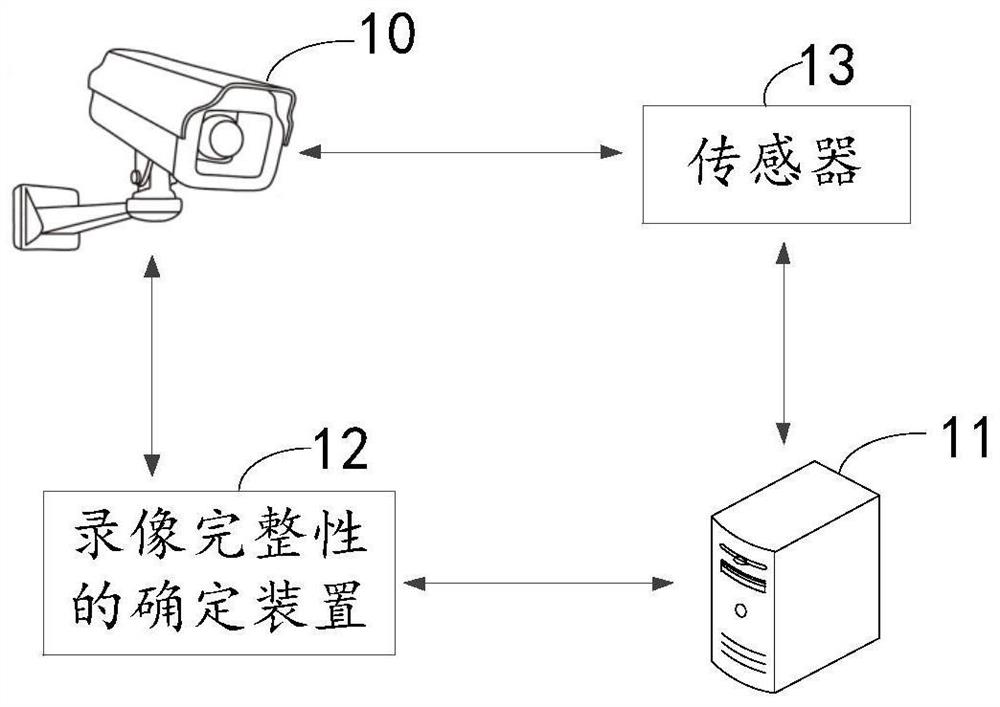

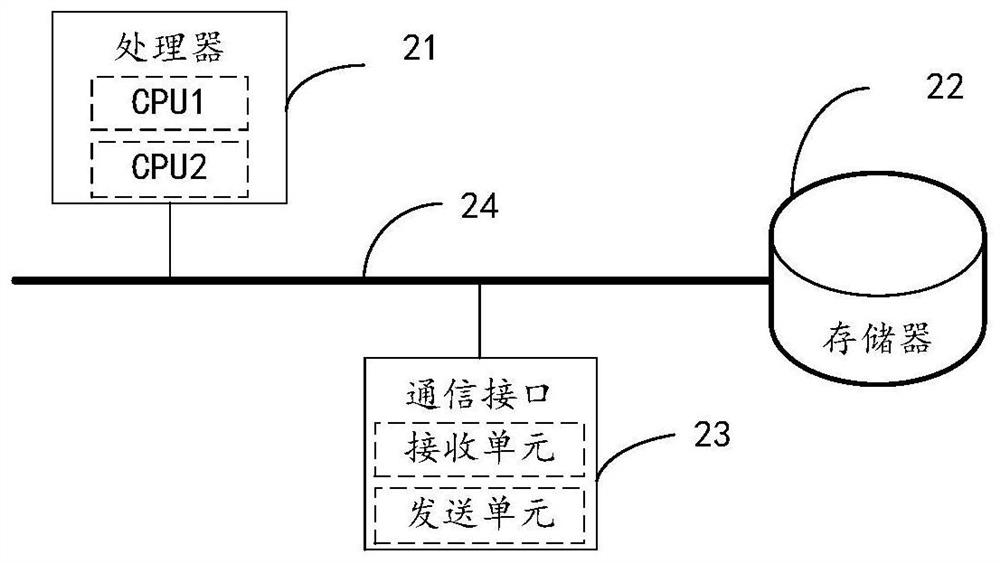

Video integrity determination method and device and readable storage medium

ActiveCN112752100AIntegrity determinationAvoid problems with inaccurate resultsTelevision systemsVideo monitoringTime information

The invention provides a video integrity determination method and device, and a readable storage medium, relates to the technical field of video monitoring, and solves the problem of inaccurate determination result in the video integrity determination method. The video integrity determination method comprises the following steps: acquiring state information of a trigger event and time information of a video file, wherein the trigger event is used for triggering generation of a video file, the state information comprises an event starting moment of the trigger event, and the time information comprises a video recording starting moment and a video recording ending moment of the video file; and determining the integrity of the video file according to the state information and the time information.

Owner:HANGZHOU HIKVISION SYST TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com