Corrosion method for original austenite grain size of tempered troostite and martensite structures

A technique of tempering troostite and prior austenite, which is applied in the field of prior austenite grain size testing, can solve problems such as inaccurate results of grain size, and achieve the goal of avoiding inaccurate results, accurate ratings, and clear grain boundaries Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

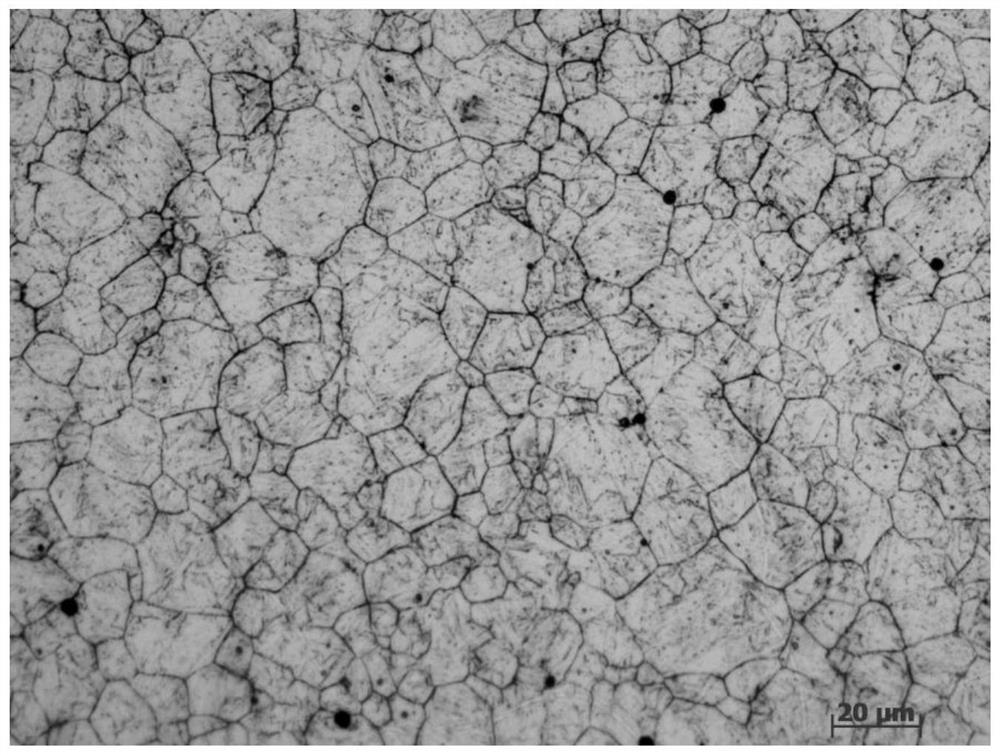

[0023] The corrosion method of the original austenite grain size of tempered troostite and martensite structure, taking the original austenite of tempered troostite or martensite structure as the sample, pretreatment first, and holding at 500°C for 4h After that, quickly cool it in water, then grind and polish it, then clamp the sample with tweezers, completely immerse it in the corrosion solution and stir it constantly, etch for 5 minutes, and wait until the surface turns black, take out the sample, rinse it quickly with running water, and soak it with absolute ethanol Wipe the surface with a cotton ball, dry it with a hair dryer, then observe the grain size of the sample under a metallographic microscope, and get figure 1 The austenite grain boundary diagram shown.

[0024] The preparation method of described corrosive agent is: 1) 1000mL water and 50g picric acid are boiled together, get picric acid aqueous solution after removing sundry with filter paper; 2) 500mL water is...

Embodiment 2

[0029] The corrosion method of the original austenite grain size of tempered troostite and martensite structure, the original austenite of tempered troostite or martensite structure is used as the sample, firstly pretreated, and kept at 450°C for 6h After that, quickly cool it in water, then grind and polish it, then clamp the sample with tweezers, completely immerse it in the corrosive solution and stir it continuously, etch for 8 minutes. Wipe off the reactants on the surface of the sample with absorbent cotton, dry it with a hair dryer, and then observe the grain size of the sample under a metallographic microscope.

[0030] The preparation method of described corrosive agent is: 1) 1000mL water and 50g picric acid are boiled together, get picric acid aqueous solution after removing sundry with filter paper; 2) 500mL water is boiled together with 50g sodium dodecylbenzene sulfonate, obtain Sodium dodecylbenzenesulfonate aqueous solution; 3) 500mL water and 50g ferric chlori...

Embodiment 3

[0032] The corrosion method of the original austenite grain size of tempered troostite and martensite structure, taking the original austenite of tempered troostite or martensite structure as the sample, pretreatment first, and holding at 550°C for 3h Finally, quickly water-cooled, then polished and polished, then immersed in the primary treatment solution for 0.5h, and finally clamped the sample with tweezers, completely immersed in the corrosion solution and stirred continuously, after 15 minutes of erosion, the surface turned black, took out the sample, and quickly Rinse with running water, wipe off the reactants on the surface of the sample with absorbent cotton dipped in absolute ethanol, blow dry with a hair dryer, and then observe the grain size of the sample under a metallographic microscope.

[0033]The preparation method of described corrosive agent is: 1) 1000mL water and 50g picric acid are boiled together, get picric acid aqueous solution after removing sundry with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com