Manufacturing process multivariate quality diagnosis classifier based on statistical method

A technology of manufacturing process and statistical method, applied in the direction of instruments, calculation, program control, etc., can solve problems such as complex statistical process and unfavorable application, achieve the effect of low algorithm complexity, perfect data processing, and reduce the probability of misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

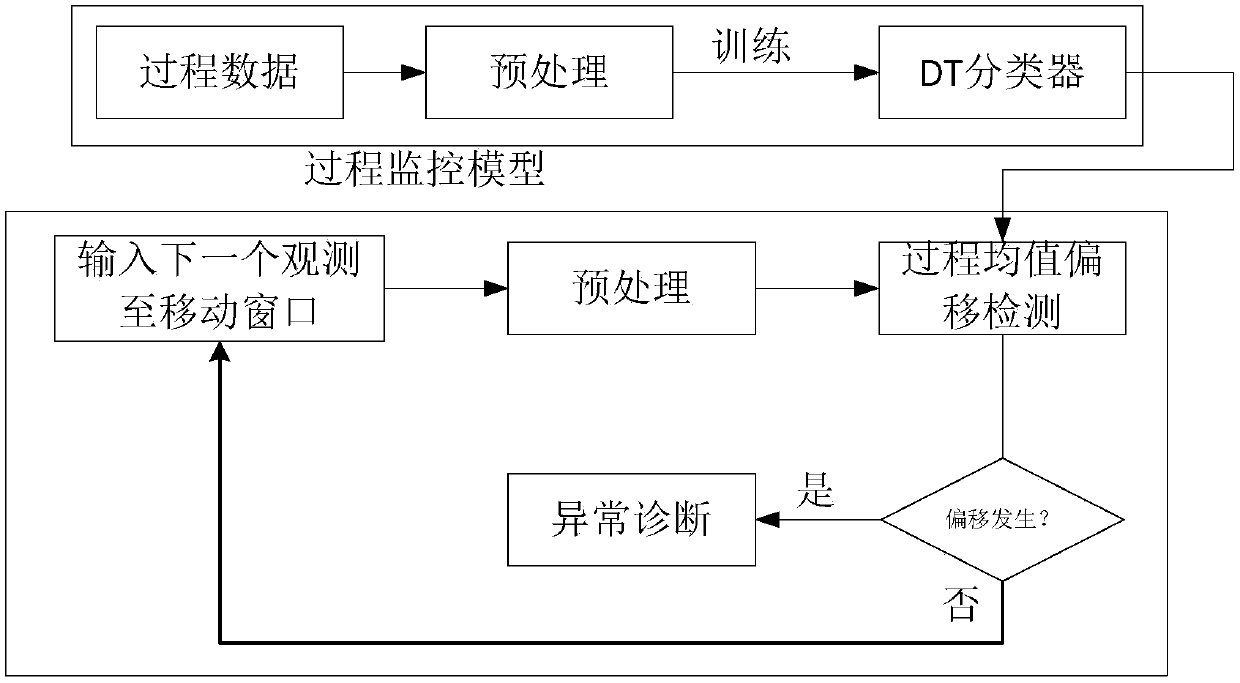

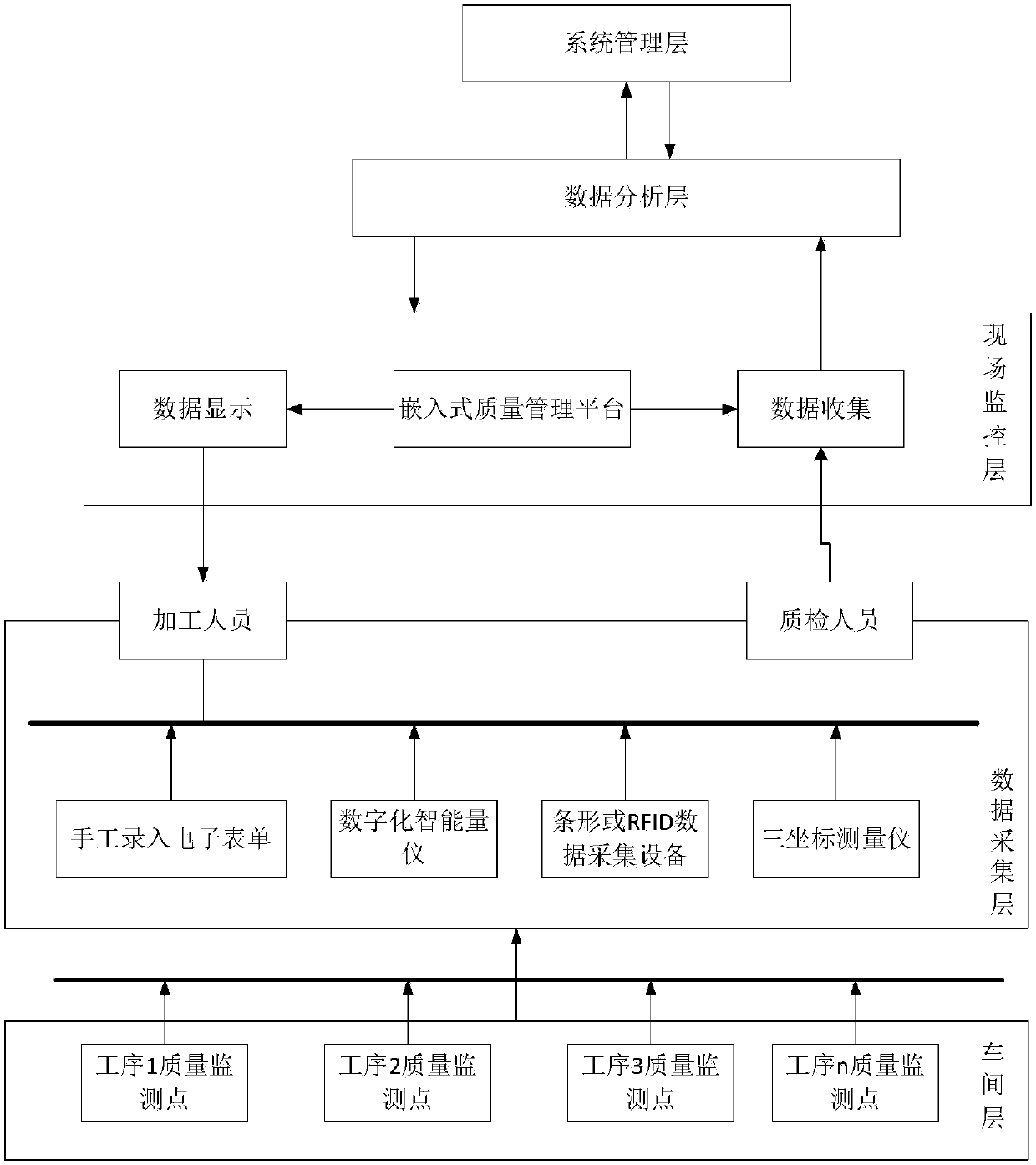

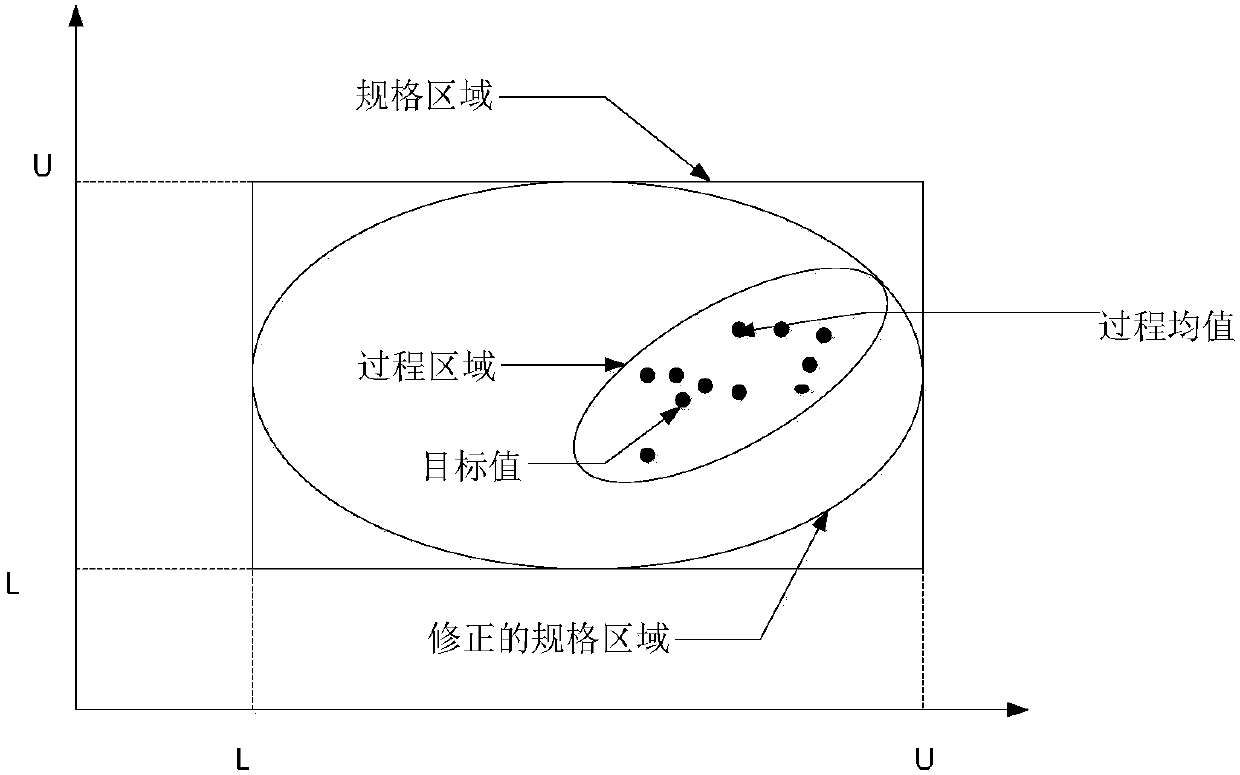

[0024] In order to solve the deficiency of multivariate control chart in multivariate process monitoring and anomaly diagnosis, combined with Figure 1-Figure 3 The present invention has been described in detail, and its specific implementation steps are as follows:

[0025] Step 1: Collect the raw data of quality characteristics in the manufacturing process, and carry out necessary sorting, simplification and calculation of the data. The specific calculation process is as follows:

[0026] In the production process, when there is no systematic error in the process, the quality characteristic value X of the product conforms to the normal distribution; because the multivariate quality characteristic value units are not uniform, and the numerical value is also large, the data needs to be further processed;

[0027] The data matrix collected by the normal operation of the production process is X n×m , n is the number of samples, m is the number of sample quality attributes.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com