CBR numerical test method for soil-stone filled subgrade soil

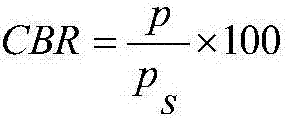

A numerical test and subgrade soil technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of large deviation of CBR value, complicated test conditions, and long time consumption, and achieve the goal of saving test cost and time cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] The present embodiment is carried out according to the following steps:

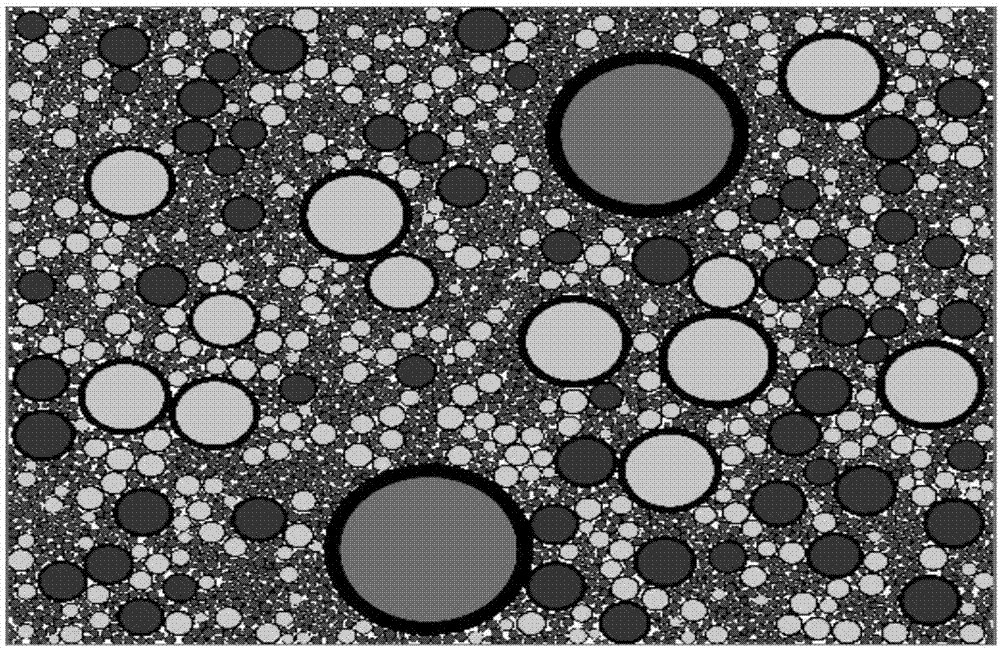

[0038] (1) According to the requirements of the specification, the earth-rock mixed subgrade soil is screened to obtain the particle size grouping, and the PFC 2DDefine the boundary according to the size requirements of the standard test mold, group the particles, set the initial void ratio and set it within a suitable range, such as 0.04, set the lower limit of the particle size of each group and the upper and lower limits of the particle size of each group According to the actual conversion, the area ratio of each group of particles is defined. Since the particles smaller than 1 mm will cause the system to collapse due to the excessive number of particles in the simulation software, or the number of generated particles will escape the boundary wall and cannot be controlled, so this embodiment does not consider the generation of particles below 1 mm;

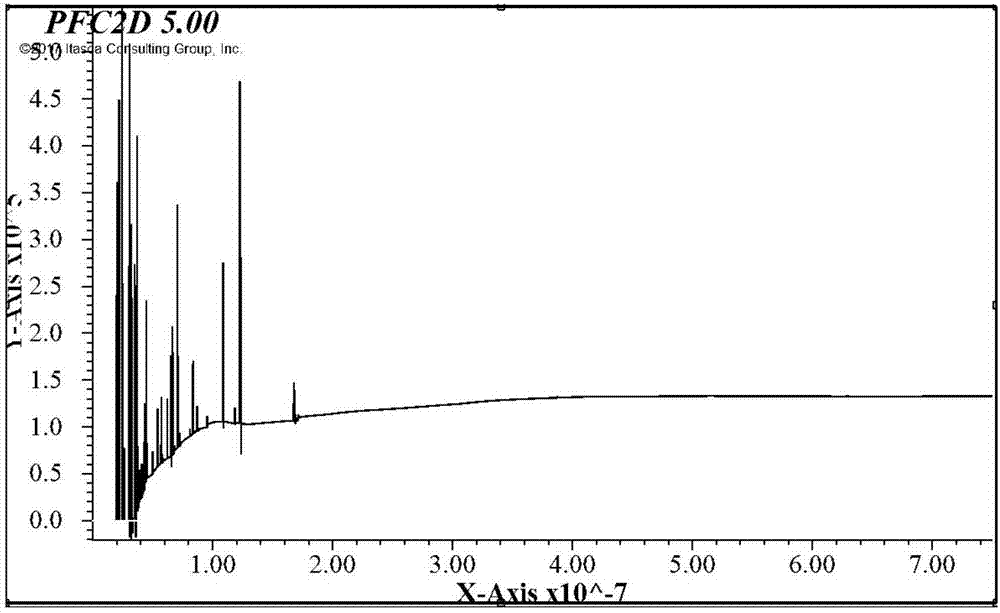

[0039] (2) Command the area domain where th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com