Live inspection device for high-voltage power equipment

A technology for high-voltage power equipment and electrical connection, applied in the field of electric power, can solve the problem of inconvenient live inspection of high-voltage power equipment, and achieve the effects of improving inspection efficiency, ensuring stable operation, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

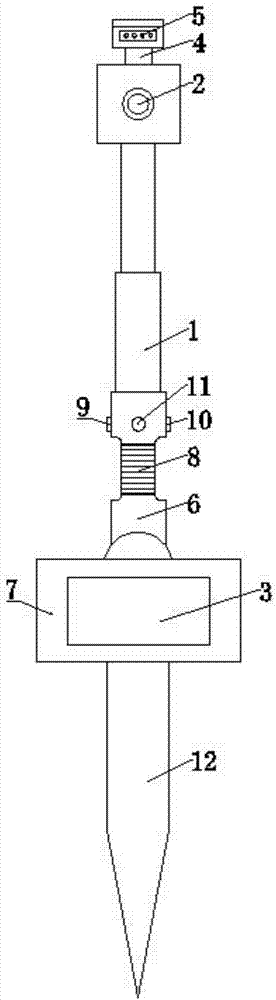

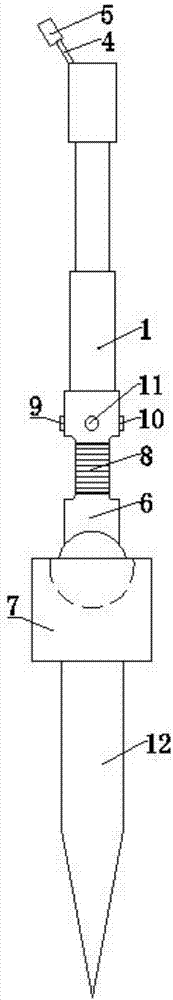

[0025] A live inspection device for high-voltage power equipment in this embodiment includes an electric telescopic rod 1, a high-definition camera 2 and a liquid crystal display 3, and a high-definition camera 2 is fixed at the telescopic end of the upper end of the electric telescopic rod 1, and the top surface of the high-definition camera 2 passes through a support plate 4. Connect the flashlight 5; the power end of the lower end of the electric telescopic rod 1 is fixed on the upper end of the support rod 6, and the lower end of the support rod 6 is fixed at the center of the top surface of the electric control box 7 through a ball joint; An extension button 9, a retraction button 10 and a camera button 11 are arranged at the same height above the holding part 8; the extension button 9 and the retraction button 10 are electrically connected to the electric telescopic rod 1, and the camera button 11 is electrically connected to the high-definition camera 2; the electric cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com