Flexible printed circuit (FPC) winding method, bearing device and cloud platform

A winding method and the technology of the cloud platform, which are applied to the arrangement of reels/photosensitive drums, TVs, cameras, etc., can solve the problems of motor torque demand fluctuations, instability, resistance, etc., and achieve enhanced accuracy , strong stability, and regular overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

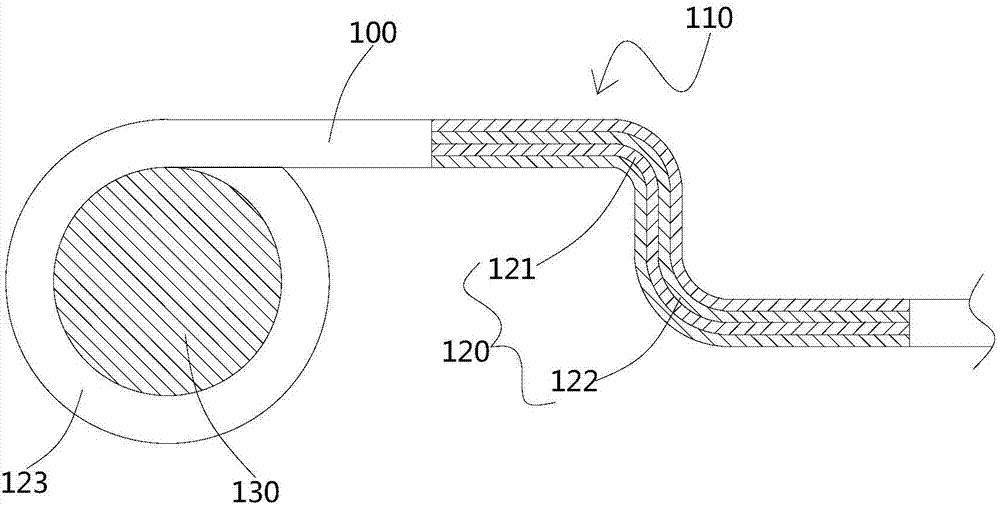

[0044] see image 3 , this embodiment provides an FPC winding method for the electrical connection of the carrier device 130 . The carrier device 130 can carry FPC wires, and the FPC wires are connected to the carrier device 130 . When the carrier device 130 moves, it will drive the FPC wire to follow the movement. The carrier device 130 may be a driving device such as a single motor or a motor group formed by multiple motors.

[0045] The FPC winding method provided by this embodiment will be specifically described below by taking the carrier device 130 as a single motor as an example:

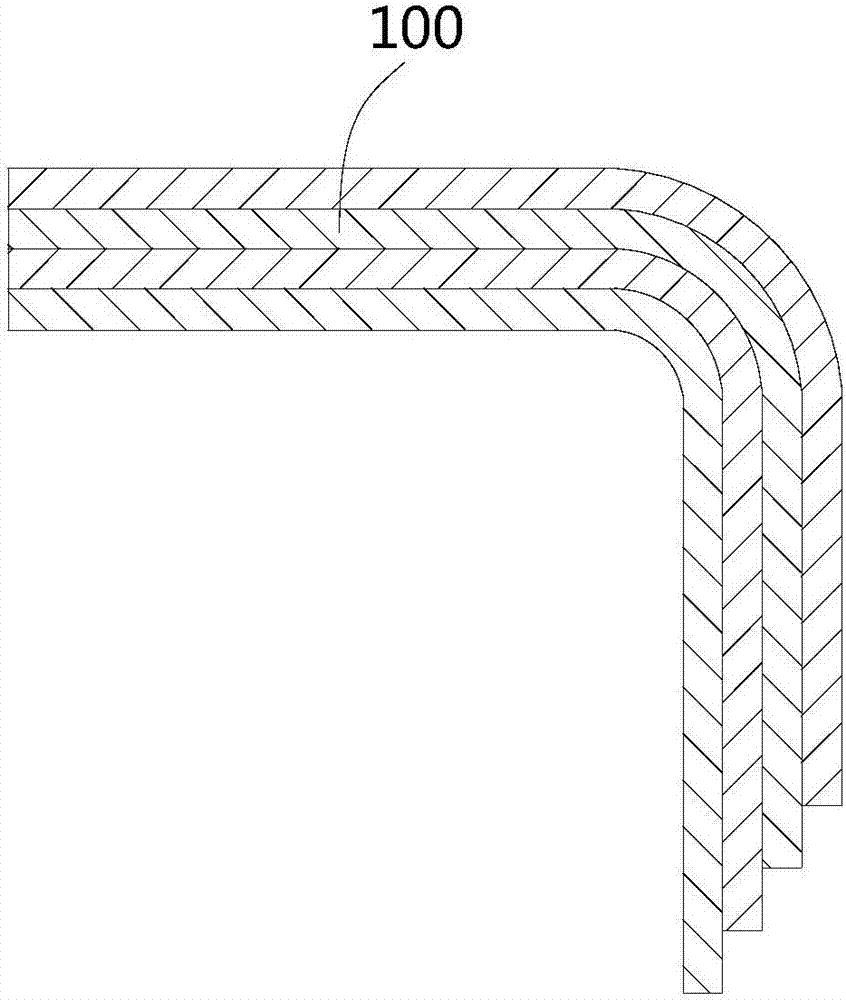

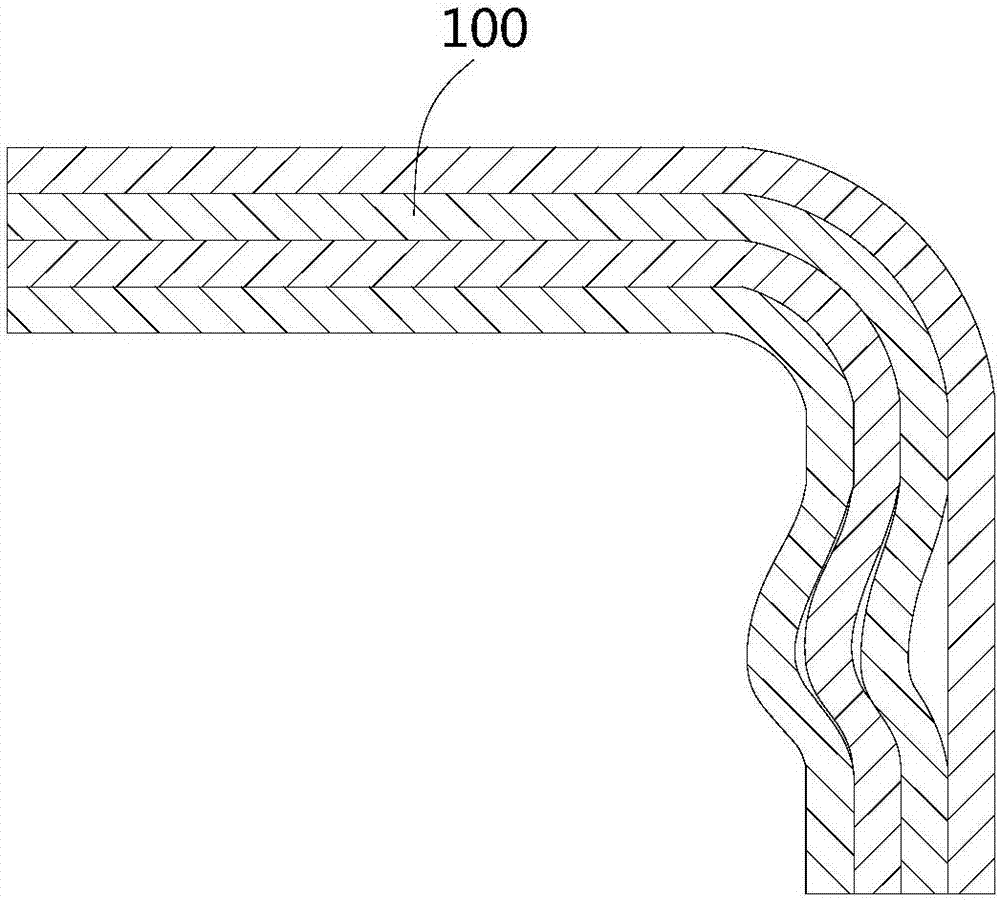

[0046] This FPC winding method includes stacked multilayer FPC100, and the multilayer FPC100 is wound around the motor to form a winding structure 110. The winding structure 110 has at least one pair of internal force offset units 120, and the internal force offset unit 120 includes a first bending The first bent portion 121 and the second bent portion 122 have opposite bending directions....

no. 2 example

[0060] This embodiment provides an FPC winding method, which is specifically applied to the carrier device 130 driven by three axes on the basis of the FPC winding method provided in the first embodiment. In this embodiment, the structure of the carrier device 130 refers to the structure of the pan / tilt provided in the fourth embodiment. see Figure 9 to Figure 15 The carrier device 130 includes a first drive member (refer to the pitch motor 610 in the figure), a second drive member (refer to the yaw motor 620 in the figure), and a third drive member (refer to the roll motor 630 in the figure) , components (refer to the camera module 640 in the figure), a first wire passing structure 650 and a second wire passing structure 660 .

[0061] It should be understood that the first driving member, the second driving member and the third driving member may be motors or other driving devices. The axes of the first driving member, the second driving member and the third driving membe...

no. 3 example

[0071] see Figure 8, the present embodiment provides a carrying device 500, this carrying device 500 includes a carrier device 130 and a multi-layer FPC100 stacked, the multi-layer FPC100 is wound on the carrier device 130 to form a winding structure 110, the winding structure 110 has at least A pair of internal force canceling units 120 , the internal force canceling unit 120 includes a first bending portion 121 and a second bending portion 122 , and the bending directions of the first bending portion 121 and the second bending portion 122 are opposite.

[0072] It should be understood that the carrying device 500 is a device carrying the carrier device 130 , and the electrical connection between other components is realized through the multi-layer FPC 100 wound on the carrier device 130 . The carrying device 500 can be applied to the fields of aircraft, boats, motor vehicles, aircrafts, etc., and can be an image stabilization device, for example, it can be a pan-tilt applie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com