Wastewater treatment precipitation device and operating method thereof

A wastewater treatment and sedimentation device technology, which is applied in water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc., can solve the problems of inconvenience, delay in construction period, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

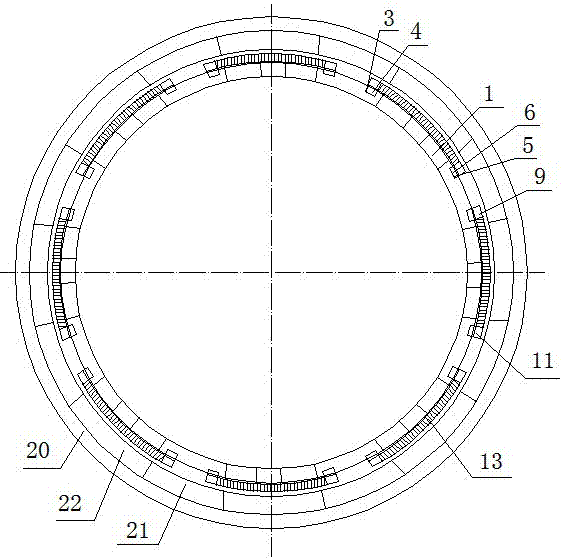

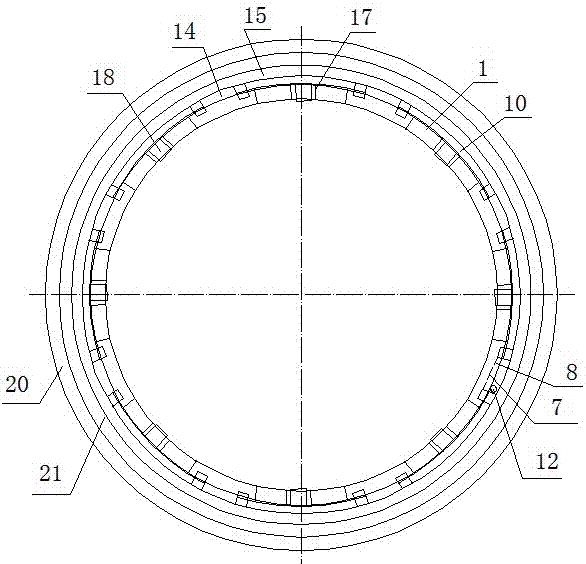

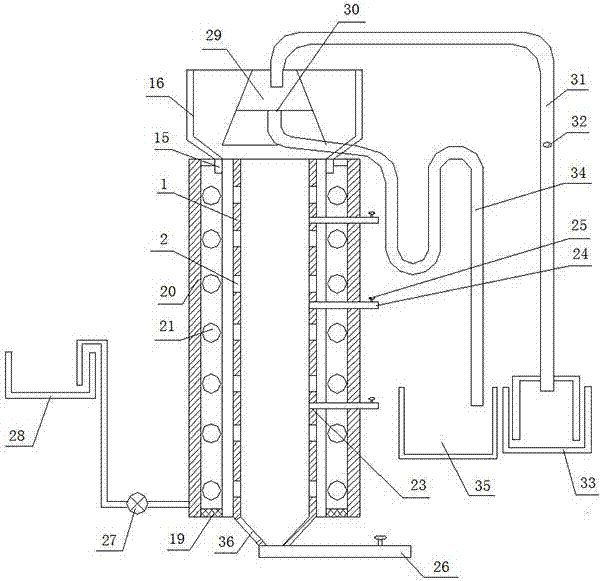

[0020] A kind of waste water treatment sedimentation device, its composition comprises: Waste water treatment tank 1, in described waste water treatment tank is sludge sedimentation area, described waste water treatment tank has a group of circulating water inlet holes 2, described circulating water inlet The holes are distributed around the circumference of the wastewater treatment tank, the circulating water inlet holes are vertically arranged on a straight line, and one side of the vertically arranged circulating water inlet holes is provided with a left vertical mosaic groove 3, so The left vertical mosaic groove is connected to the left vertical magnetic plate 4, and the other side of the vertically arranged circulating water inlet hole is provided with a right vertical mosaic groove 5, and the right vertical mosaic groove is connected to the right vertical magnetic plate 6, The bottom of the left vertical mosaic groove and the right vertical mosaic groove is connected thr...

Embodiment 2

[0025] An operation method of a wastewater treatment and sedimentation device. The filter screen frame is inserted into the outside of the wastewater treatment tank, and then attached to the outside of the wastewater treatment tank. Combine the left fixed magnetic plate, the right vertical magnetic plate, attract the right fixed magnetic plate, and the bottom magnetic plate to attract the bottom fixed magnetic plate to fix, and then assemble the iron ring to fix the top shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com