Vertical multi-spindle drilling machine with adjustable spacing

A multi-axis drilling machine and spacing adjustment technology, which is used in boring/drilling, drilling/drilling equipment, metal processing equipment, etc. , high labor intensity of workers, etc., to achieve the effect of simple structure, long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

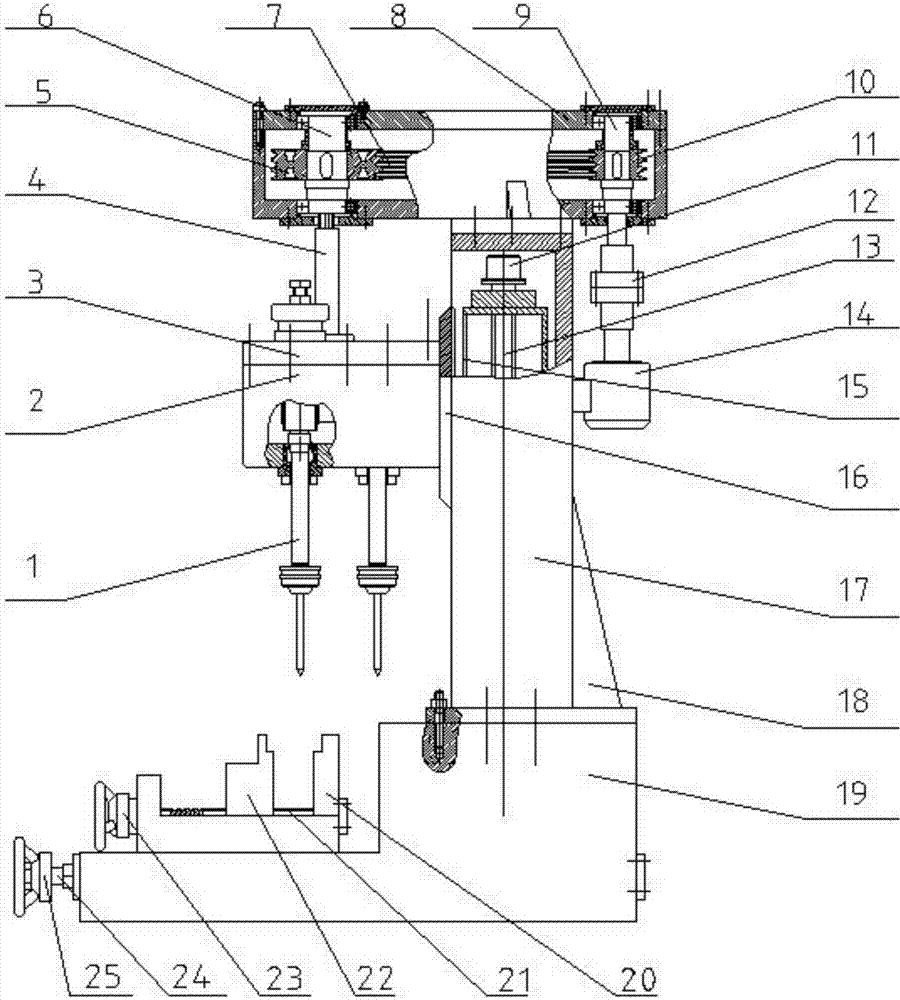

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

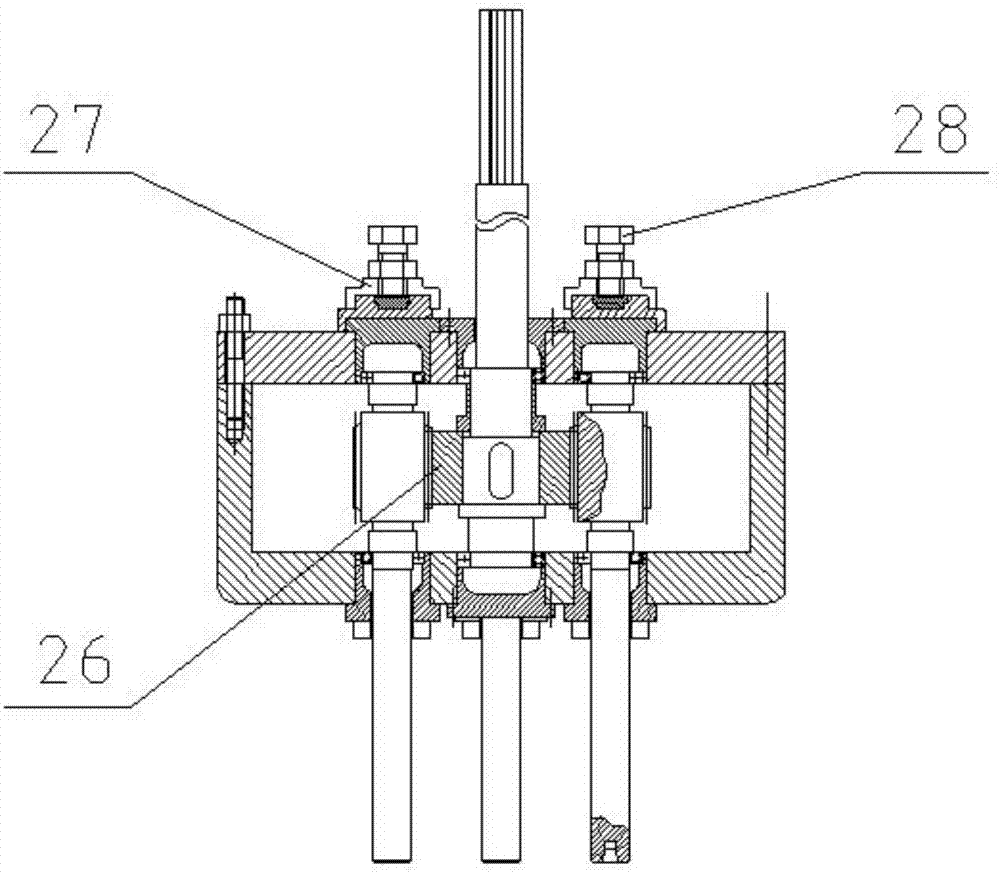

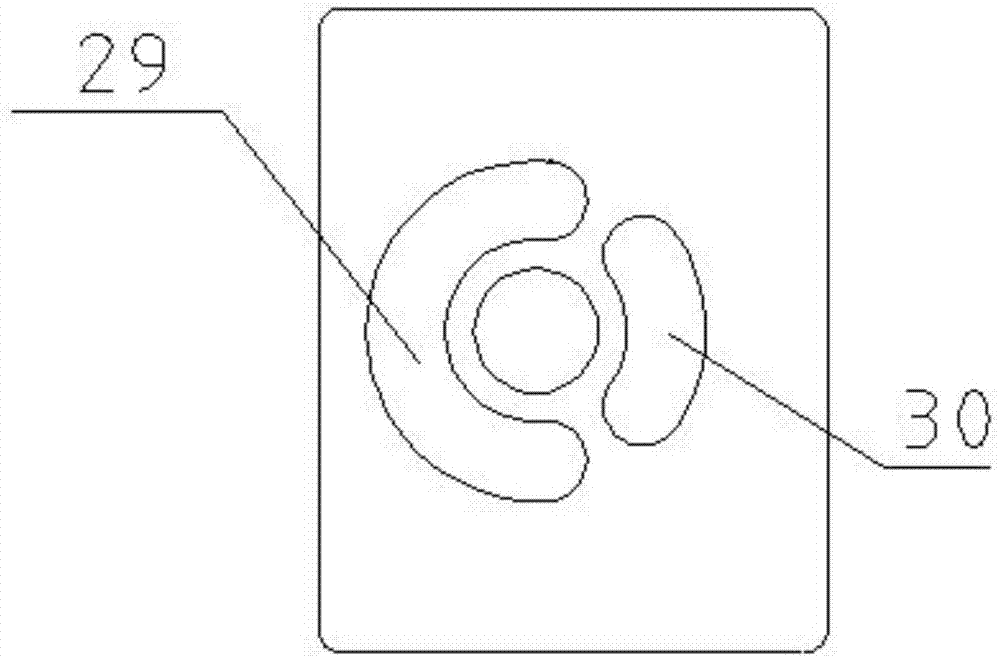

[0023] The vertical multi-spindle drilling machine with adjustable spacing as shown in the figure includes drill shaft 1, gear box 2, gear box cover 3, main shaft 4, driven pulley 5, driven pulley shaft 6, belt 7, and pulley box 8. Driving pulley shaft 9, driving pulley 10, servo motor 11, elastic coupling 12, screw 13, main motor 14, linear guide rail 15, sliding platform 16, frame 17, support rib 18, base 19, Fixed block 20, workpiece clamping screw 21, moving block 22, clamping hand wheel 23, workpiece position adjustment screw 24, position adjustment hand wheel 25, driving gear 26, distance adjustment slider 27, distance adjustment nut 28, long Arc hole track 29, short arc hole track 30.

[0024] The output shaft of the main motor 14 and the driving pulley shaft 9 are connected by an elastic coupling 12, the driven pulley shaft 6 and the main shaft 4 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com