Automatic rotary disc type press-in machine

A rotary table type, press-in machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency of manual pressing, and achieve the effects of novel structure, tight coordination and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

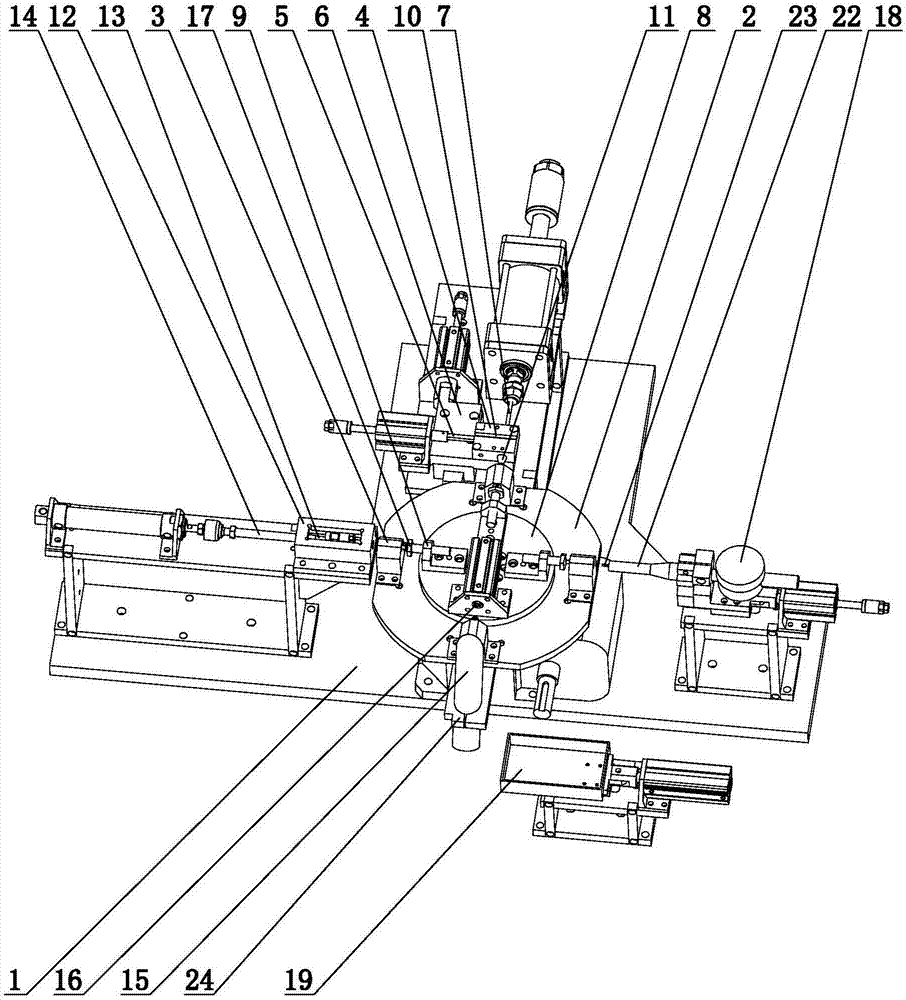

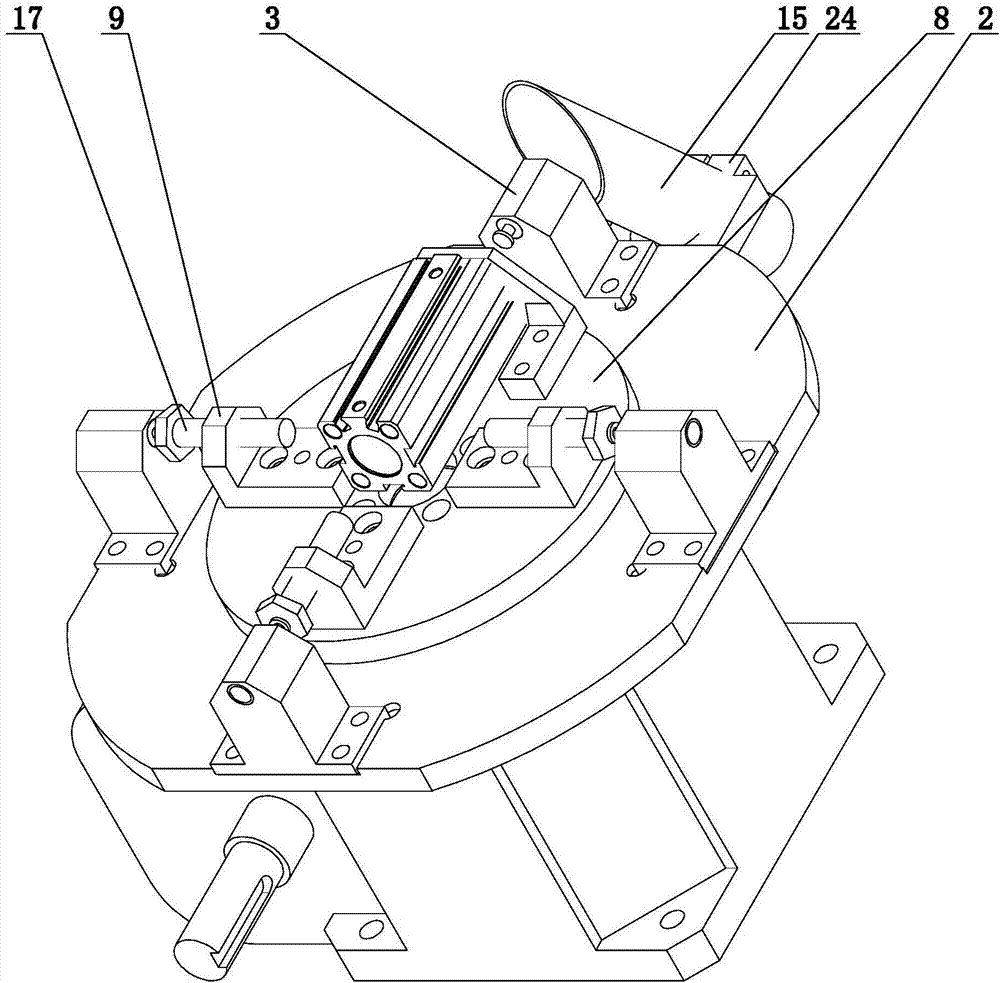

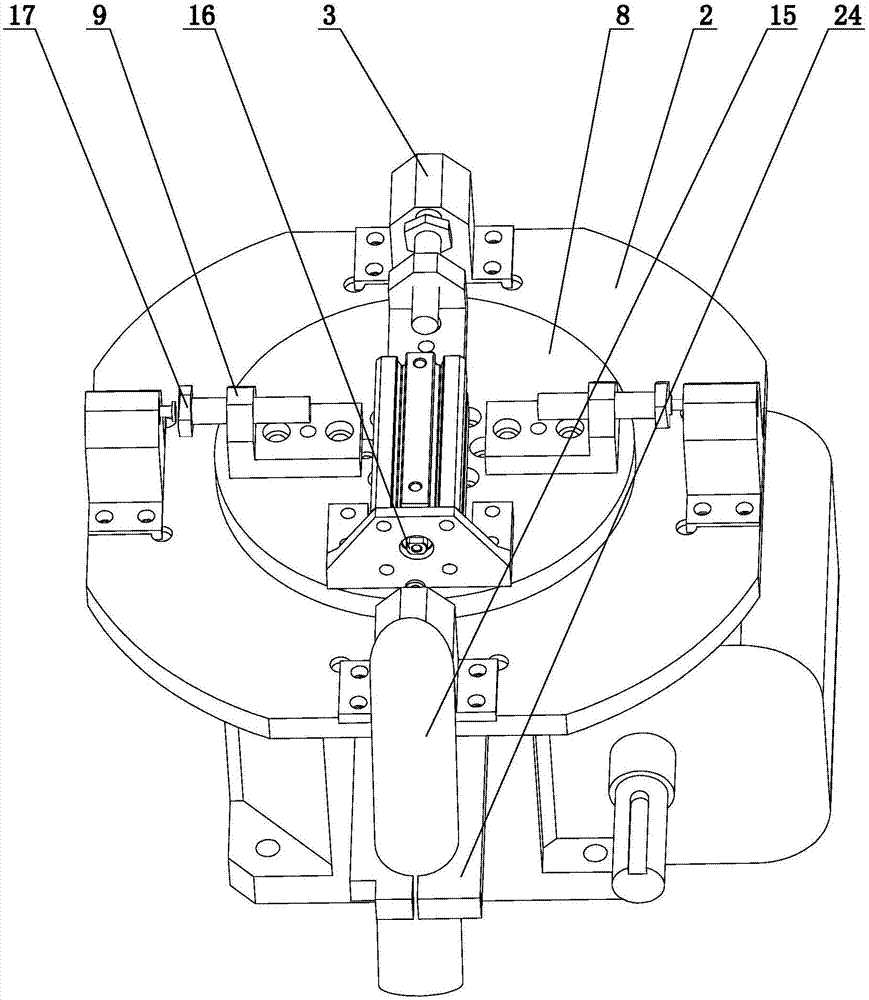

[0028] Such as Figure 1~11 The automatic turntable pressing machine shown includes a bottom plate 1, which is T-shaped, and a turntable 2 is provided at the cross position of the bottom plate 1, and the turntable 2 is round as a whole, and the inner end, outer end, left end and right end edges are It is flat and straight, corresponding to 4 positions, convenient to install the fixing seat 3, and the corresponding position on the edge surface of the turntable 2 is recessed to form an installation groove, which makes the installation and fixing of the fixing seat 3 more firm. There is a divider under the turntable 2, and the turntable 2 and the divider The output shaft of the outer ring is connected, one end of the input shaft of the divider is connected with the stepping motor of the turntable, and the other end of the input shaft of the divider is connected with a signal wheel. The signal wheel rotates once, and the outer diameter gradually changes from small to large. A sens...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that the baffle seat and the mounting plate of the pusher cylinder are evenly distributed on the three-divided position of the circle. In order to improve the efficiency, some parts only need to be processed, because the processing rate is very high, within the specified range Inside.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap