Integrated composite oil-water separator

An oil-water separator and composite material technology, which is applied in the field of integrated composite oil-water separator, can solve the problems of large site area, complicated installation, and it is difficult to solve the separation and collection of oil and debris on the ground in the gas station area. The effect of promoting the use and reducing the use area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

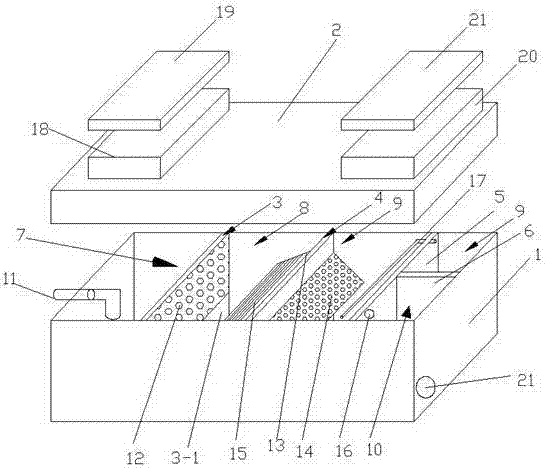

[0035] like figure 1 The one-piece composite material oil-water separator shown includes a box body 1 and a cover plate 2 arranged on the box body 1, and the box body 1 passes through a partition A3, a partition B4, a partition C5 and a partition D6, the box body 1 is divided into a sediment separation area 7, an oil-water separation area 8, an oil pollution recovery area 9 and a water discharge area 10, and an observation port A18 is provided on the cover plate 2 above the sediment separation area 7. A18 is provided with a sealing cover plate A19, and the tank 1 located in the sediment separation area 7 is provided with a water inlet pipe 11, and the lower half of the partition A3 is a flat plate 3-1, which occupies part of the partition One-third of the whole of A3, the upper part of the partition A3 is provided with a plurality of filter holes 12, one side of the partition B4 is provided with a mounting plate 13, and the other side of the partition B4 is provided with a fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com