Sealing detection device and method for battery pack and battery pack

A sealing detection and battery pack technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of the fluid, etc., can solve the problem of battery system damage, poor sealing, and poor battery pack sealing Detection and other problems to achieve the effect of maintaining performance and delaying service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

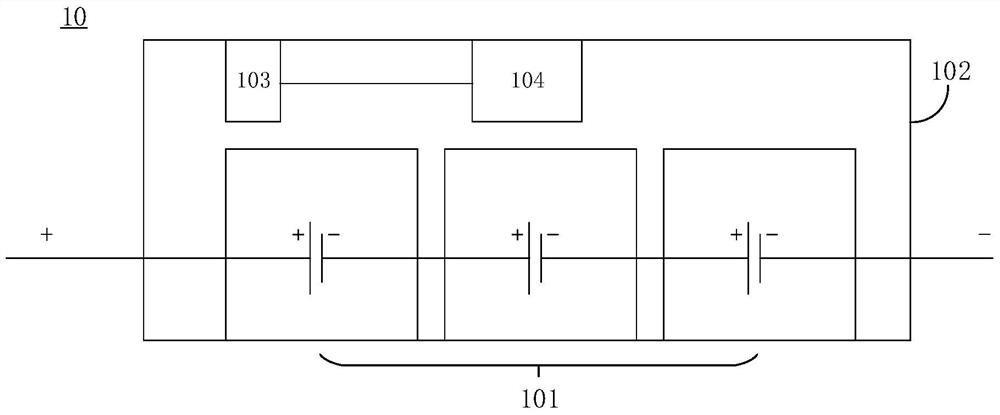

[0040] figure 1 A schematic structural diagram of a battery pack according to an embodiment of the present invention is shown. Such as figure 1As shown, the battery pack 10 may include: a battery pack 101 , a pack body 102 and a battery management system (BMS) 103 , wherein the BMS 103 and the battery pack 101 are arranged in the pack body 102 . The BMS 103 can be used to perform battery management on the battery pack 101 , including but not limited to: battery voltage, temperature and current sampling, battery balancing, charging and discharging management, and the like. In addition, if figure 1 As shown, an air pressure detection device 104 is also provide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap