Test bench and test method of chassis driving test of robot

A driving test, robot technology, applied in the test of machine/structural components, motor generator test, mechanical component test, etc., can solve the problem that the motor operating point data cannot be captured, the motor driving ability, the efficiency and the chassis endurance are unpredictable and unpredictable. Design evaluation, long development time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

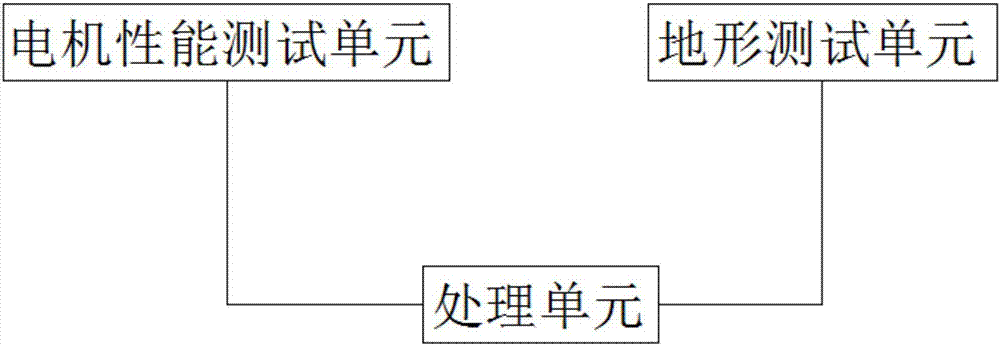

[0036] According to one aspect of the present invention there is provided a robot chassis drive test bench, comprising:

[0037] The motor performance test unit, the motor performance test unit includes: a first dynamometer and a first transmission device, the first dynamometer is connected to one end of the first transmission device, and the output shaft of the motor to be tested is connected to the other end of the transmission device during use ;

[0038] The terrain test unit, the terrain test unit includes: the second dynamometer and the second transmission device;

[0039] Wherein, the second transmission device includes a terrain transmission shaft and a terrain sleeve, one end of the terrain transmission shaft is connected to the second dynamometer, the terrain sleeve is sleeved on the terrain transmission shaft, and the motor to be tested is in contact with the terrain sleeve during use. The motor to be tested can drive the terrain sleeve to rotate;

[0040] Wherein...

Embodiment 1

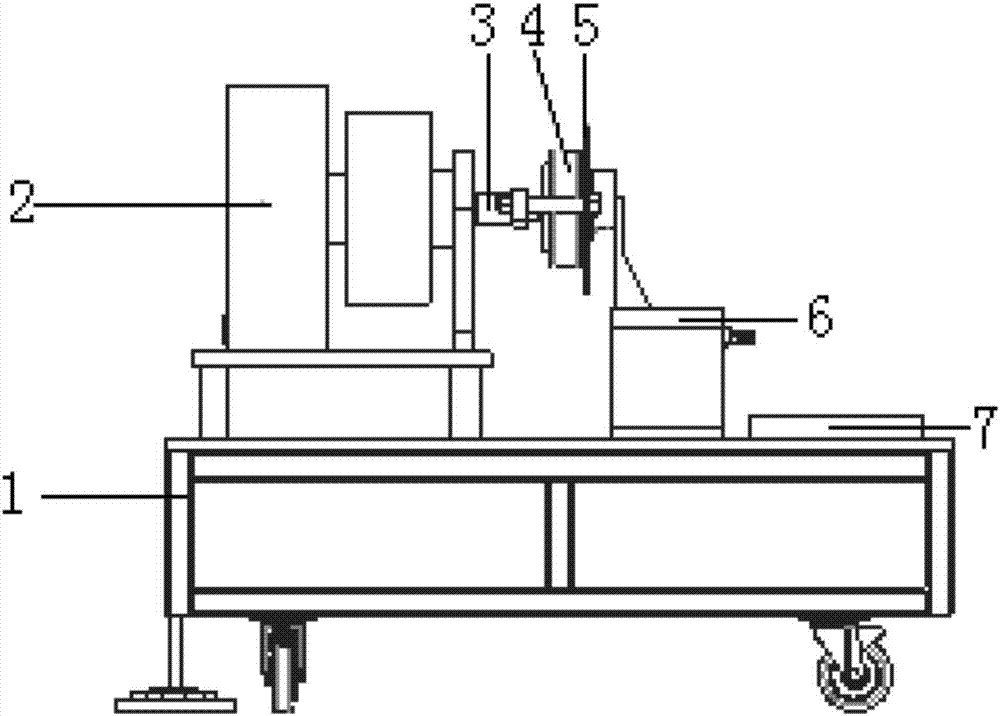

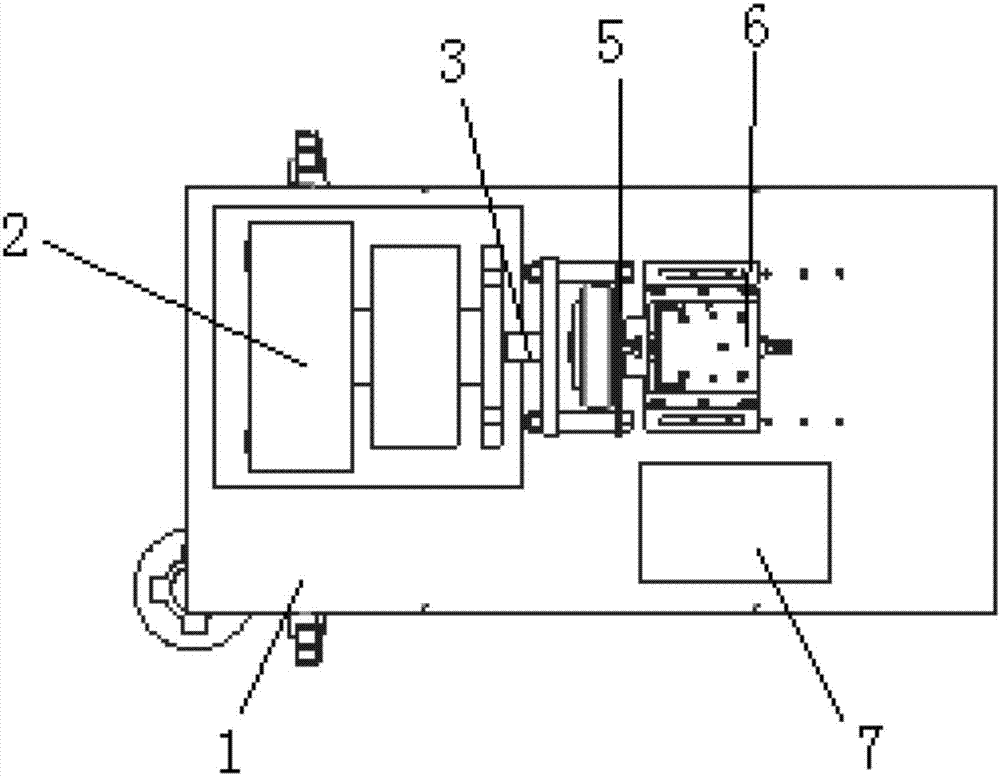

[0060] figure 1 A schematic structural diagram of a robot chassis driving test bench according to an embodiment of the present invention is shown. figure 2 A front view of a motor performance testing unit according to an embodiment of the present invention is shown. image 3 A top view of a motor performance testing unit according to an embodiment of the present invention is shown. Figure 4 A left side view of the motor performance testing unit according to an embodiment of the present invention is shown. Figure 5 A front view of a terrain testing unit according to an embodiment of the present invention is shown. Figure 6 A top view of a terrain testing unit according to an embodiment of the present invention is shown. Figure 7 A left side view of a terrain testing unit according to one embodiment of the invention is shown.

[0061] Such as Figure 1-7 As shown, the robot chassis drives the test bench, including:

[0062] The motor performance test unit, the motor p...

Embodiment approach 2

[0071] According to another aspect of the present invention there is provided a robot chassis drive test method, the robot chassis drive test method comprising:

[0072] Connect the output shaft of the motor to be tested to the first transmission device, start the motor to be tested to obtain the motion parameters of the motor to be tested through the first dynamometer, and send the motion parameters to the processing unit;

[0073] Specifically, when in use, the first dynamometer applies a load to the motor to be tested, and the load is selected according to actual needs. The first dynamometer obtains the motion parameters of the motor to be tested, and the user can obtain the motion parameters of the motor to be tested through the processing unit. The parameters are compared with the motion parameters of the actual required motor, and then it is determined that the motor to be tested can meet the requirements of normal use.

[0074] Remove the motor to be tested, and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com