Method for operating a washing machine having an electrochemical sensor and washing machine

An electrochemical and sensor technology, used in the control device of washing machines, other washing machines, household appliances, etc., can solve the problems of signal distortion of the sensor, poor signal of the sensor, and the lack of analyzable processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

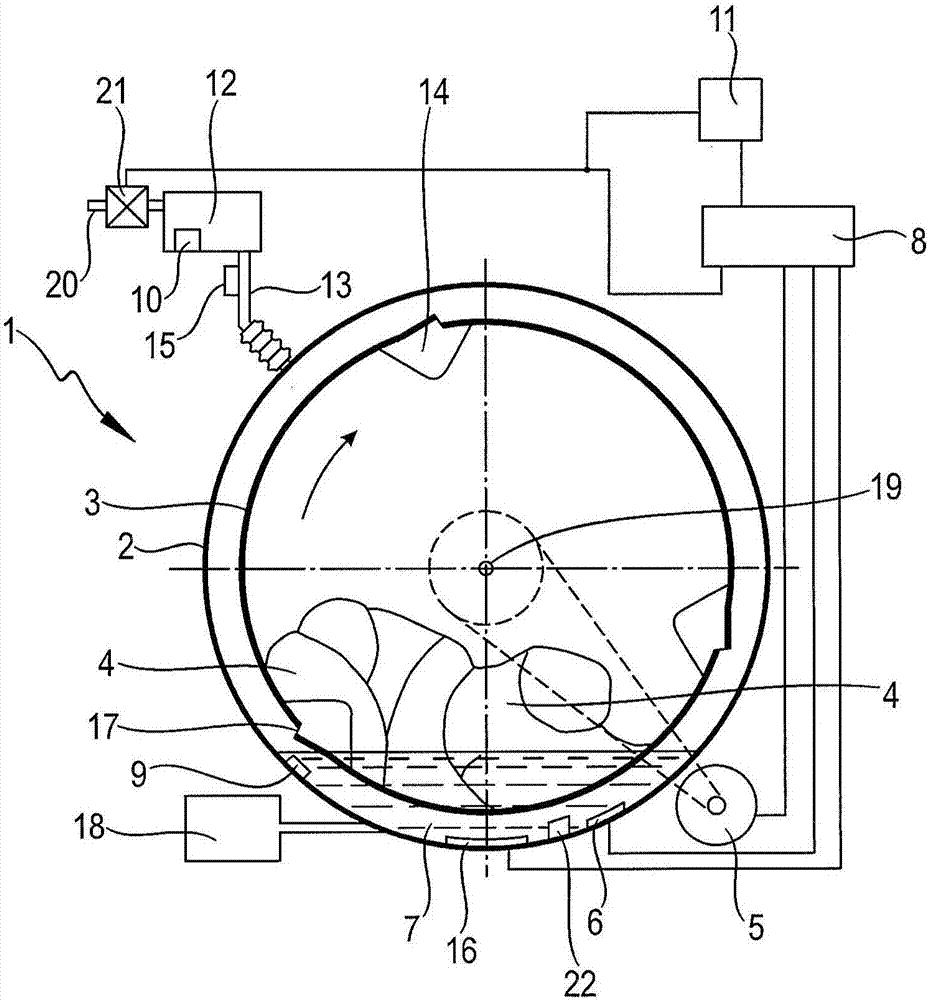

[0078]The washing machine 1 of the drawing has a lye container 2 in which a drum 3 is rotatably mounted and can be driven by a drive motor 5 . In order to achieve improved ergonomics, the axis of rotation 19 of the drum 3 is oriented upwardly and frontally at a small angle (eg 13°) from the horizontal, so that the user of the washing machine 1 can reach and see inside the drum 3 more easily. In addition, this arrangement also achieves a counter-use of the washing lye in cooperation with the laundry carrier 14 on the inner surface of the drum shell and the suction device 17 for the aqueous liquid containing detergent, for example the washing lye 7 . 7 Intensification of soaked laundry 4. In the embodiment shown here, the laundry carrier 14 is asymmetrical, so that for the two possible directions of rotation of the drum 3 the lye container 2 is The aqueous liquid 7 in moves with different ranges of action (Ausmaβ). This influence is taken into account in the control unit 8 so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com