Electronic device

A technology of electronic equipment and terminals, which is applied in the field of electronic equipment and can solve problems such as damage to sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

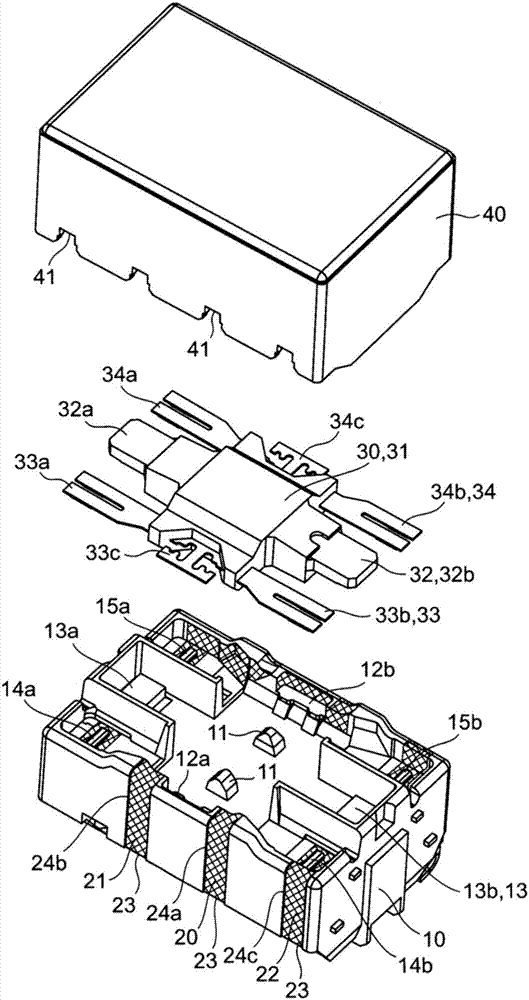

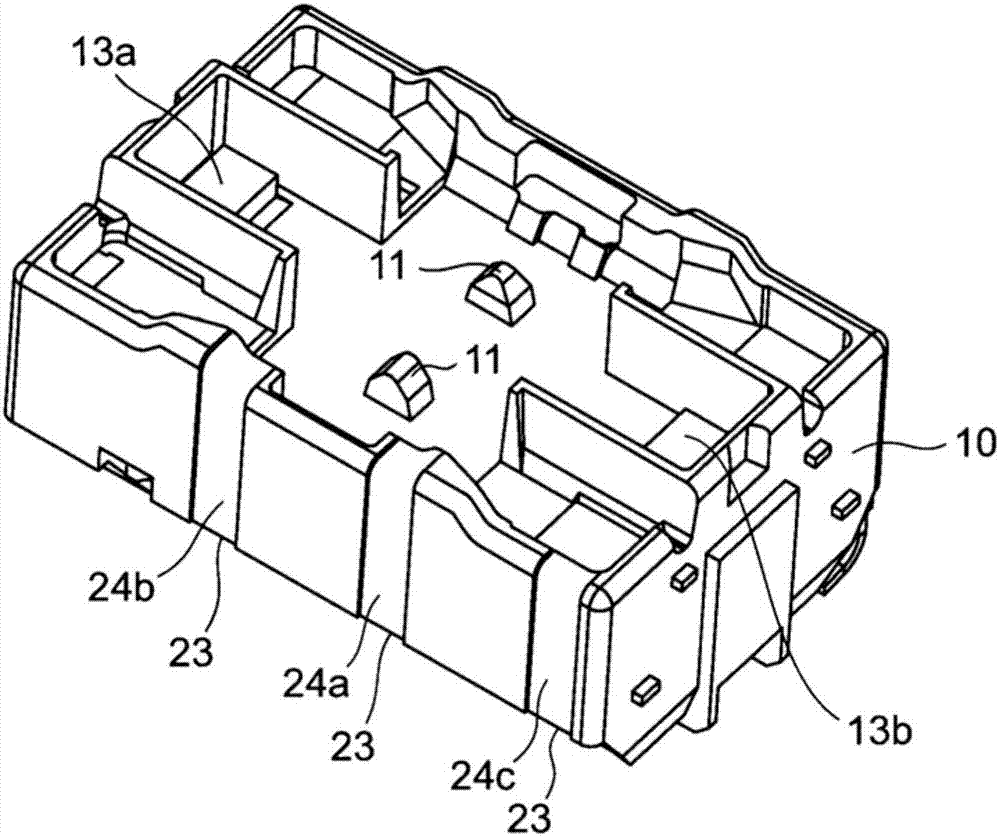

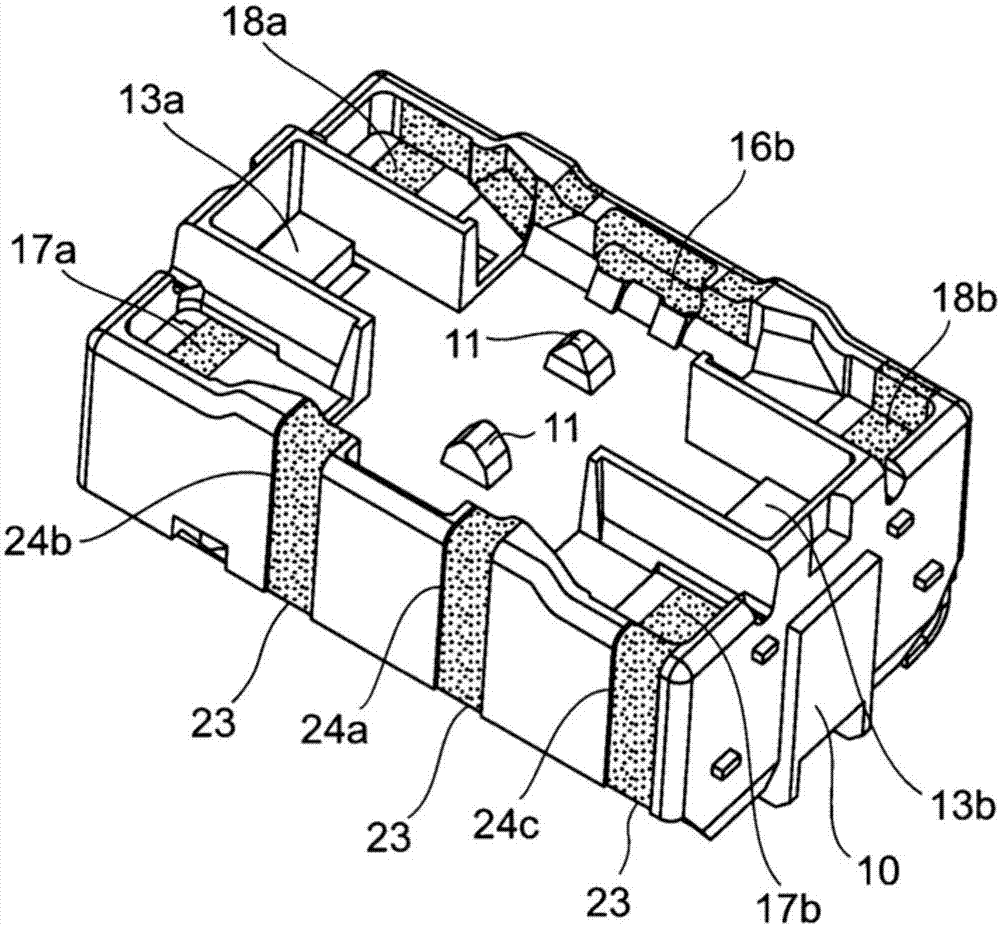

[0057] refer to Figure 1 to Figure 19 Embodiments of the electronic device of the present invention will be described.

[0058] Such as Figure 1 to Figure 7 As shown, the first embodiment is applied to an electromagnetic relay, and has an insulating base 10 , a movable contact piece 30 , and a cover 40 .

[0059] Such as figure 1As shown, the insulating base 10 is insert-molded with a gate-shaped cross-section iron core 13 wound with a coil (not shown), and its molding material contains basic polymer, filler and metal powder. Examples of the basic polymer include liquid crystal polymer (LCP) and polybutylene terephthalate (PBT). Furthermore, the insulating base 10 is provided with a pair of support protrusions 11, 11 protruding from the center of the bottom surface thereof. Common electrodes 12a, 12b are disposed on both sides of the supporting protrusions 11, 11. In addition, the magnetic pole portions 13a, 13b of the iron core 13 are exposed at positions facing each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com