Parallel type imitated handmade noodle twisting and thinning machine and use method

A hand-imitating, parallel-connected technology, which is applied in the direction of dough forming machinery or equipment, application, baking, etc., can solve the problems of high output, slow operation, etc., and achieve simplification of manual kneading, easy parts, and time saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

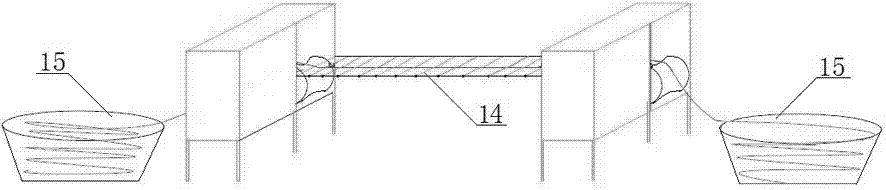

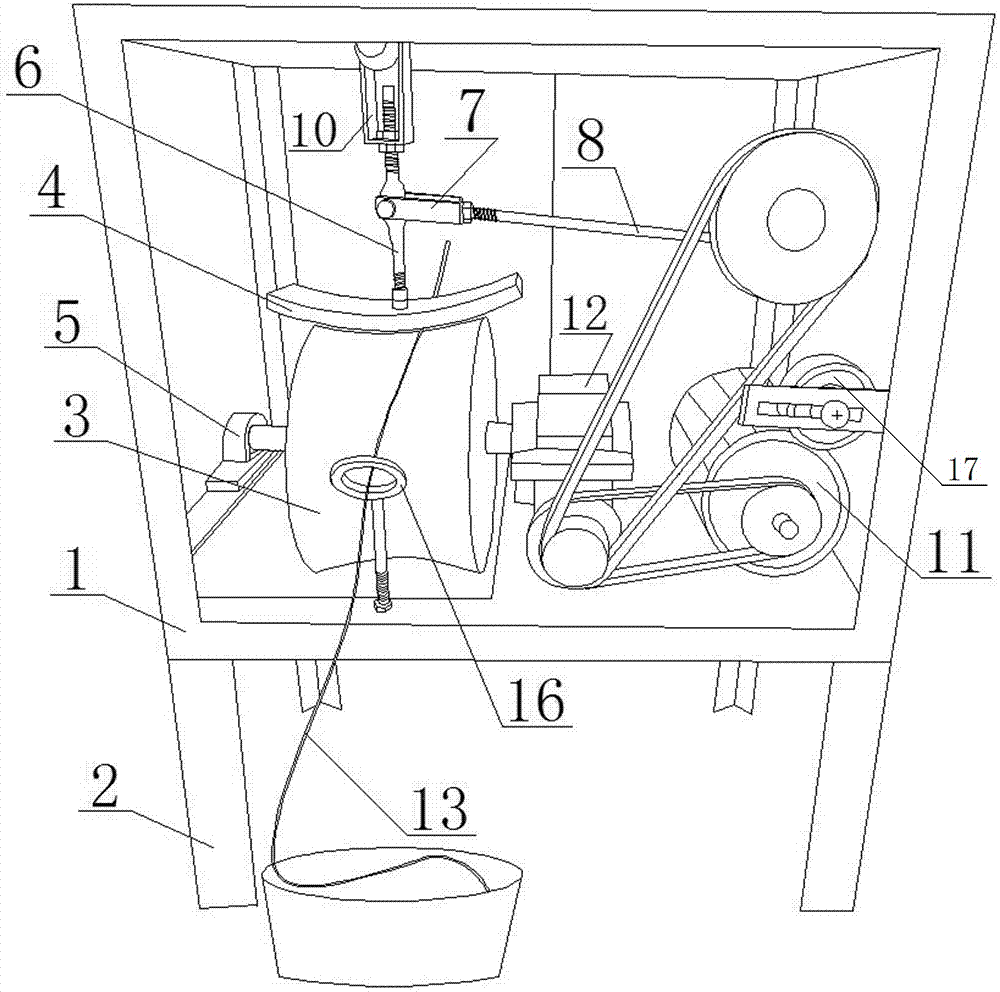

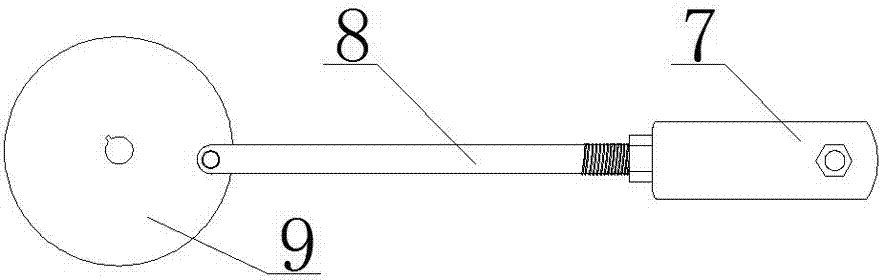

[0021] As shown in the figure, a parallel imitation manual noodle rolling machine includes a frame body 1, which is supported by outriggers 2. The frame body has a noodle entry and exit channel. mechanism, the power mechanism provides power for the transmission mechanism, and the noodle twisting mechanism includes a concave roller 3 in the circumference and an arc-shaped washboard 4. Bearing 5, the shaft at the other end is connected to the bearing and then connected to the transmission mechanism, and the transmission mechanism drives the inner concave roller 3 to rotate; the arc-shaped washboard 4 is above the inner concave roller 3 and has a distance from the inner concave surface. The radian of the washboard 4 is the same as that of the concave surface of the concave roller 3 in the circumference, and the outer arc of the washboard 4 is opposite to the concave surface of the concave roller 3 in the circumference; 6 is connected to the top of the frame body 1, the connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com