Drawer type dish-washing machine distributor

A dishwasher and dispenser technology, which is applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, cleaning equipment, etc., can solve the problem of damage to the dispenser, affecting the washing efficiency of the dishwasher, Problems such as poor sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

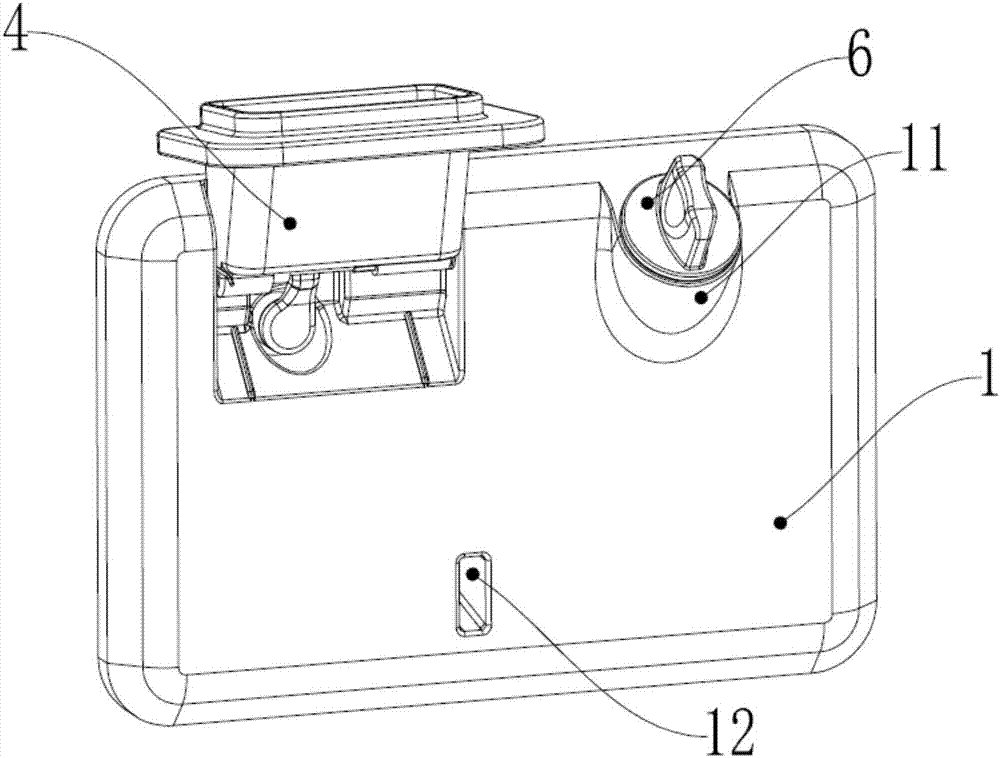

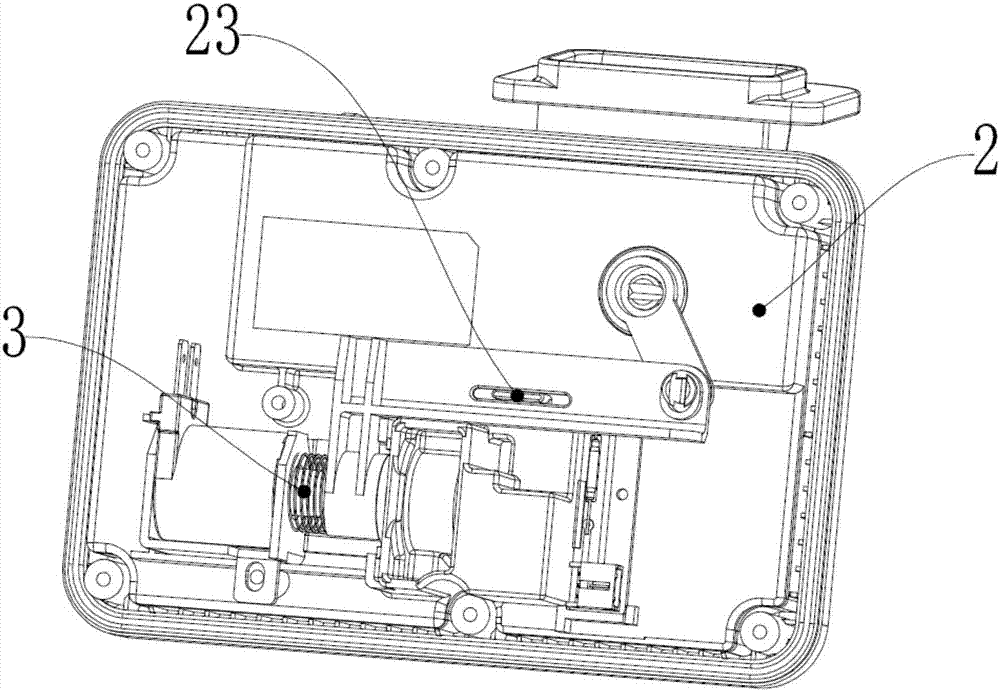

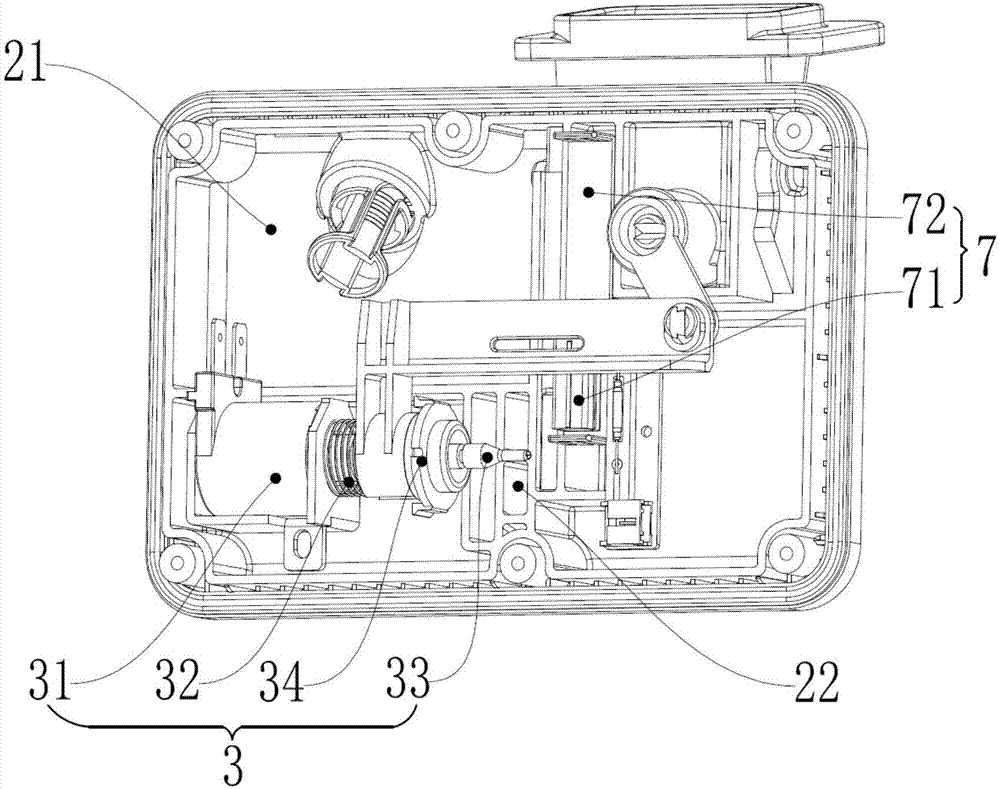

[0026] A drawer-type dishwasher dispenser, comprising a face cover 1, a bottom cover 2, a drive mechanism 3, a dishwashing powder chamber mechanism 4 and a connecting rod transmission mechanism 5; the face cover 1 and the bottom cover 2 are formed by welding A chamber 21 and a temporary chamber 22 for accommodating dishwashing liquid, the face cover 1 is provided with a liquid inlet 11 and a liquid outlet 12, the liquid outlet 12 communicates with the temporary chamber 22, and the drive mechanism 3 is provided On the bottom cover 2, the dishwashing powder chamber 4 is arranged on one side of the liquid inlet 11; the dishwashing powder chamber mechanism 4 includes a powder box 41, a rotating shaft 42 and a stop block 43, The powder box 41 is rotatably arranged on the face cover 1 through the rotating shaft 42, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com