Manufacturing method for cabinet door of disinfection cabinet

A manufacturing method and disinfection cabinet technology, applied in disinfection, sanitary equipment for toilets, coatings, etc., can solve the problems of cumbersome operation, single disinfection method, and long disinfection time, so as to simplify disinfection operations, improve disinfection efficiency, and improve The effect of disinfection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

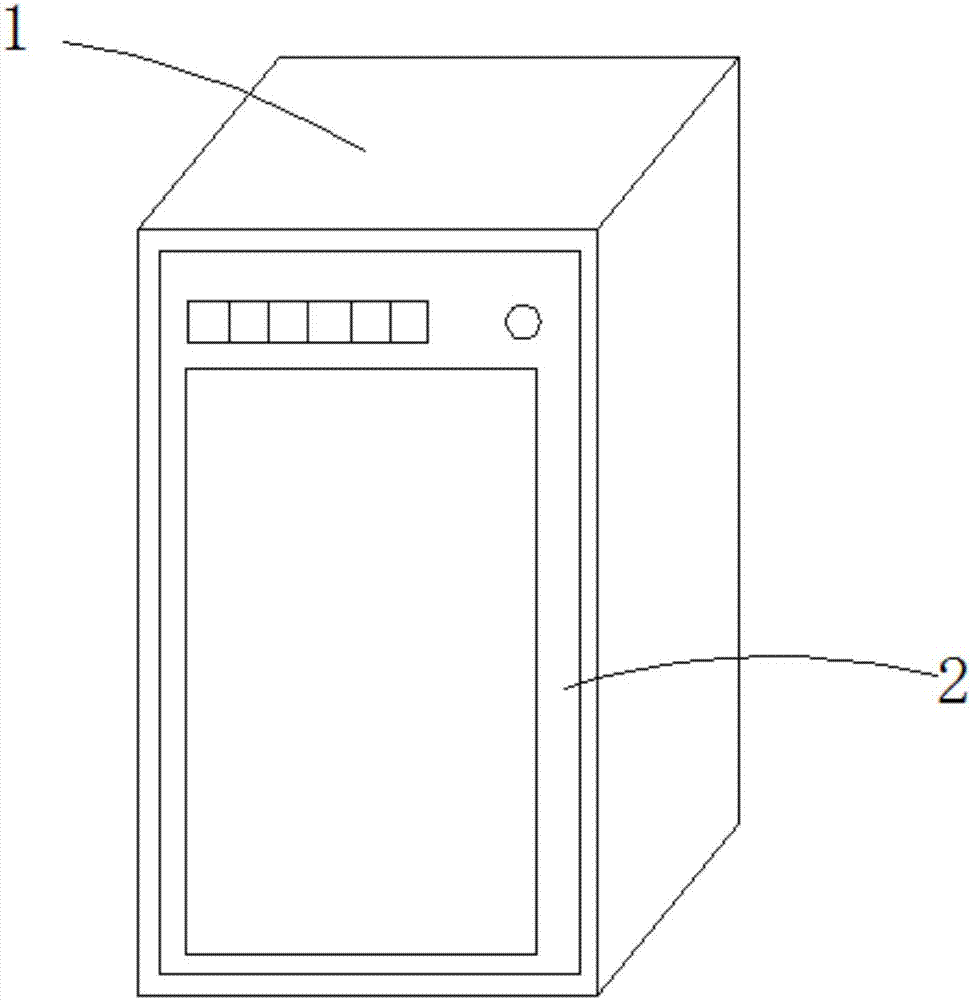

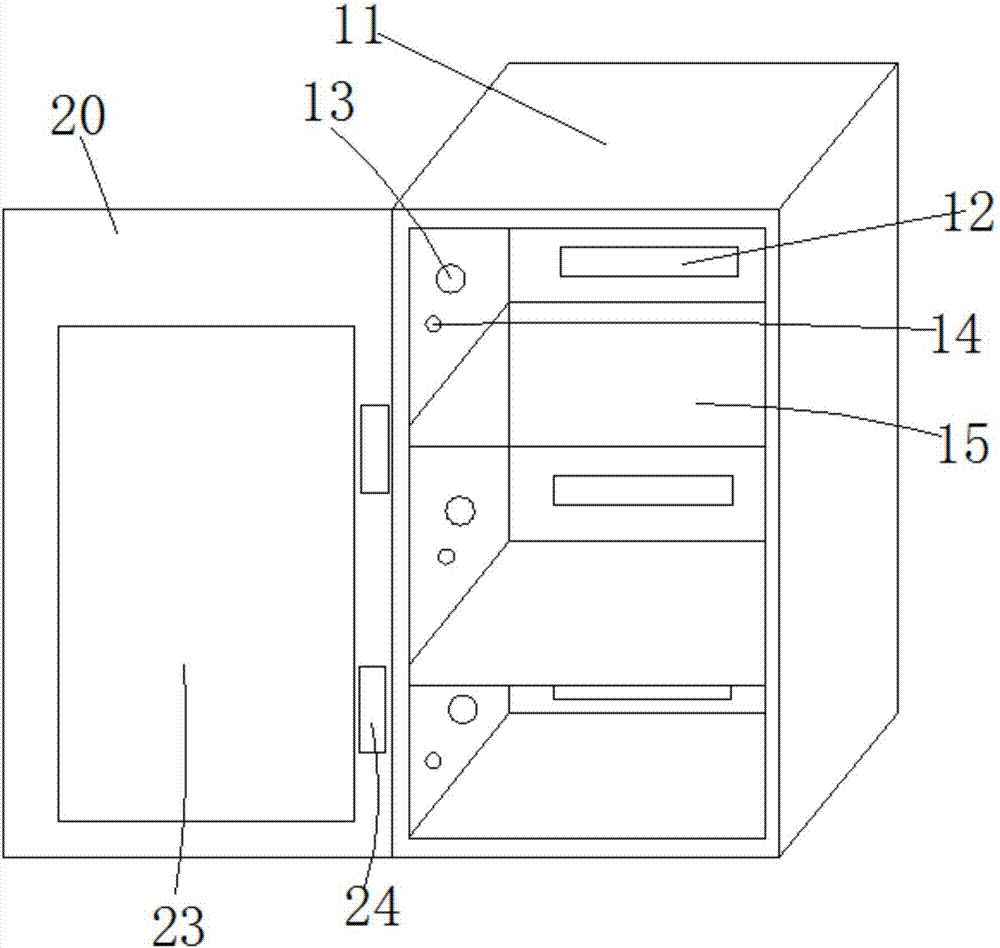

[0031] Such as Figure 1 to Figure 4 As shown, the present invention provides a disinfection cabinet, comprising: a cabinet body 1, and a cabinet door 2 connected to the cabinet body 1;

[0032] The cabinet 1 includes: a cabinet body 11, a plurality of sequentially arranged disinfection chambers arranged in the cabinet body 1, an infrared heating tube 12 arranged in each disinfection chamber, an ultraviolet disinfection lamp 13, a sensor Grating 14, partition 15 located between each adjacent disinfection chamber;

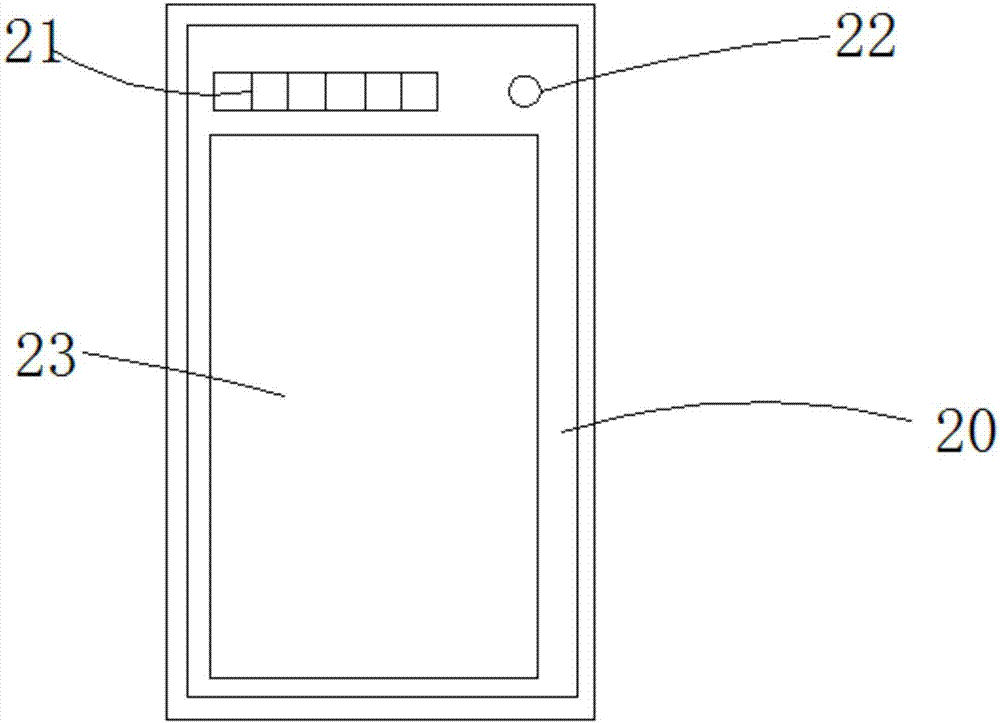

[0033] The cabinet door 2 comprises: a cabinet door body 20, a transparent observation window 23 embedded in the cabinet door body 20, a travel switch 24 arranged between the cabinet door body 20 and the cabinet body 11, and a set For the disinfection chamber switch 21 and the power switch 22 on the front of the cabinet door body 20, each disinfection chamber corresponds to a disinfection chamber switch 21;

[0034] The infrared heating tube 12, ultraviolet disinf...

Embodiment 2

[0040] A method for manufacturing a cabinet door of a disinfection cabinet, the steps are as follows:

[0041] ①, structure and molding

[0042] The cabinet door is closed on the cabinet body, including the cabinet door body, the transparent observation window embedded in the cabinet door body, the travel switch arranged between the cabinet door body and the cabinet body, and the cabinet door body The disinfection chamber switch and power switch on the front of the cabinet, each disinfection chamber in the cabinet body corresponds to a disinfection chamber switch;

[0043] The cabinet door body is made of carbon steel, and the transparent observation window is made of acrylic;

[0044] ②, cabinet door body pretreatment

[0045] Spray the pretreatment liquid on the cabinet door body, and place it in a drying oven at 75°C to dry after spraying;

[0046] The pretreatment solution is composed of 60 parts of water-based acrylic modified epoxy resin, 3 parts of flame retardant, 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com