Bone ash pulverizer

A pulverizer and cremated ashes technology, which is applied in the funeral and interment field, can solve the problems of high labor intensity, manpower consumption, inconvenient use, etc., and achieve the effects of good environmental protection, saving physical strength and manpower, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

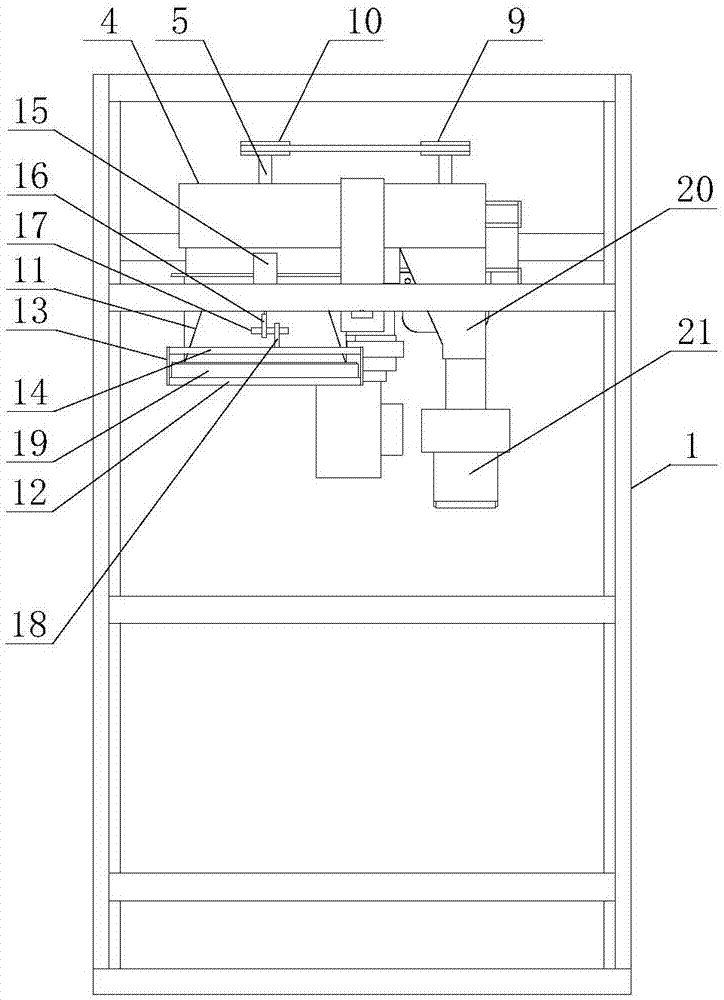

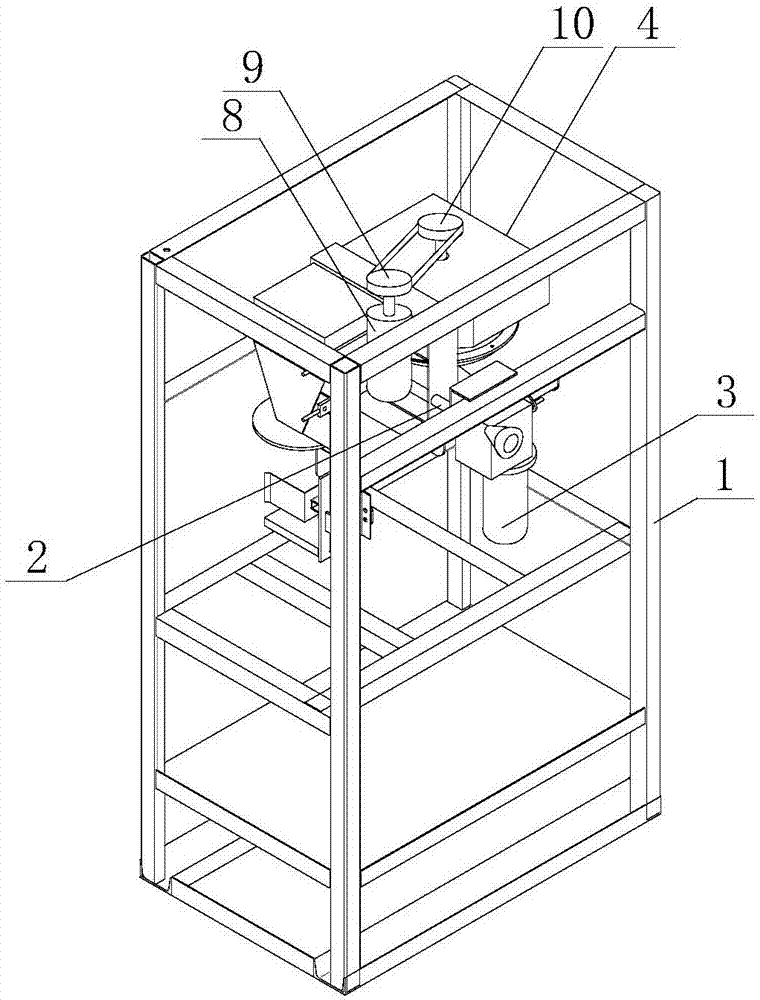

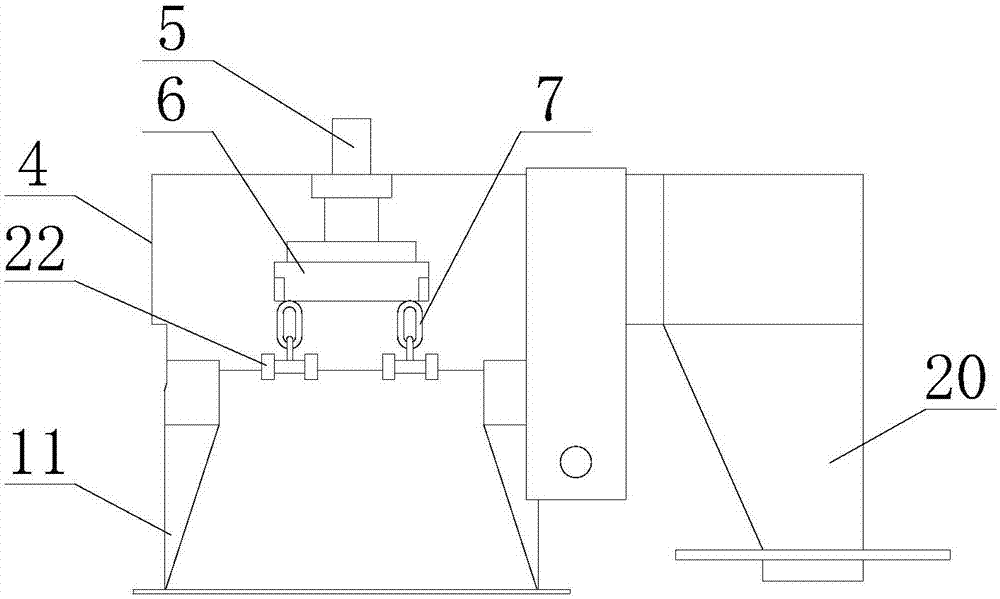

[0014] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0015] Such as Figure 1-3 As shown, the present invention discloses a columbarium pulverizer, comprising a frame 1, a main shaft 2 is horizontally installed on the frame 1 through bearings, a main motor 3 is fixed on the frame 1, and the The output shaft of the main motor 3 is fixedly connected with the rear end of the main shaft 2, and a box body 4 is fixed horizontally at the front end of the main shaft 2, and a cutter shaft 5 is vertically installed on the left end of the box body 4 through a bearing. A cutterhead 6 is fixed at the lower end of the cutter shaft 5, and the cutterhead 6 is at the left end inside the casing 4. A plurality of chains 7 are fixed on the cutterhead 6, and a chain 7 is fixed on each chain 7. Pendulum 22,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap