Automatic welding machine for lithium battery electrode lug

An automatic welding machine, lithium battery technology, applied in energy storage discharge welding, welding power source, welding equipment and other directions, can solve the problems of poor quality, low efficiency, unable to meet the high quality requirements of consumers' huge demand for lithium batteries, etc. Achieve the effect of improving welding efficiency and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

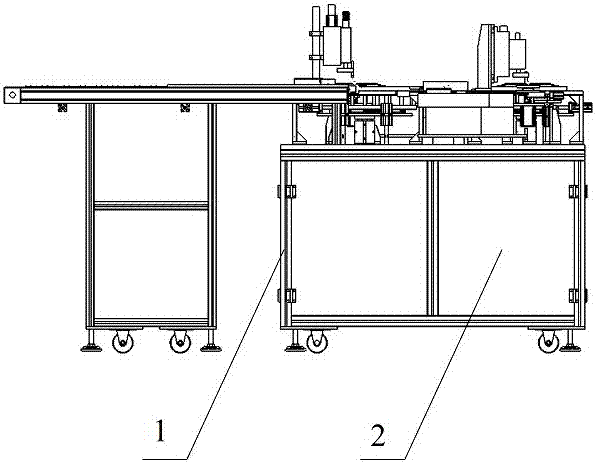

[0058] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

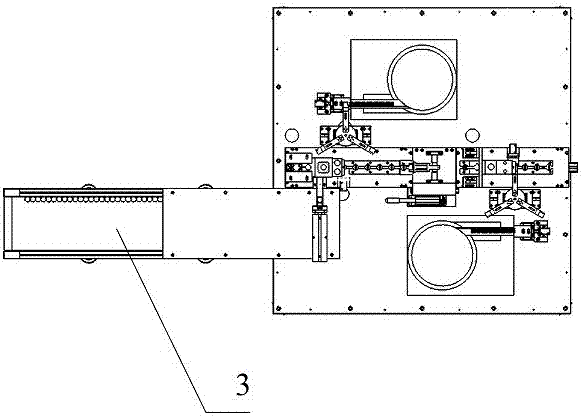

[0059] Place 12. Lithium battery cell on 11. Belt transmission mechanism of 3. Lithium battery cell input part. 11. Belt transmission mechanism drives 12. Lithium battery cell to be input along the guide groove of 10. Guide cover plate .

[0060] Further, at 3, 10 of the lithium battery cell input part, the outlet of the guide cover plate, 8, 13, the cylinder A of the lithium battery cell propelling part start, with 14, the propulsion assembly, the input 12, lithium The battery cell is pushed into 7, 16 of the lithium battery cell positioning part, and the semicircular positioning groove of the positioning mold 2.

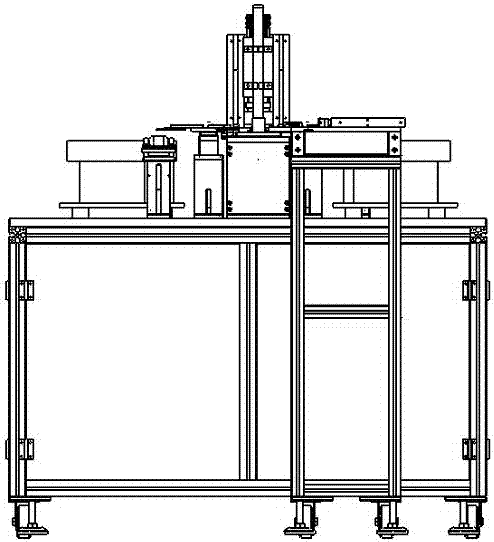

[0061] Further, 9, 21, the cylinder B of the lithium battery cell transfer part start, drive 19, the transfer ejector rod upward with 22, the vertical moving assembly, and 12, the lithium battery cell are jacked up.

[0062] Further, 9, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com