A laser marking machine focusing method, device and laser marking machine

A laser marking machine and marking head technology, applied in the field of laser marking, can solve problems such as poor marking effect, inability to achieve accurate focus adjustment, difficulty in making accurate judgments and adjustments, and achieve high consistency and overcome Invisibility, the effect of improving the marking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

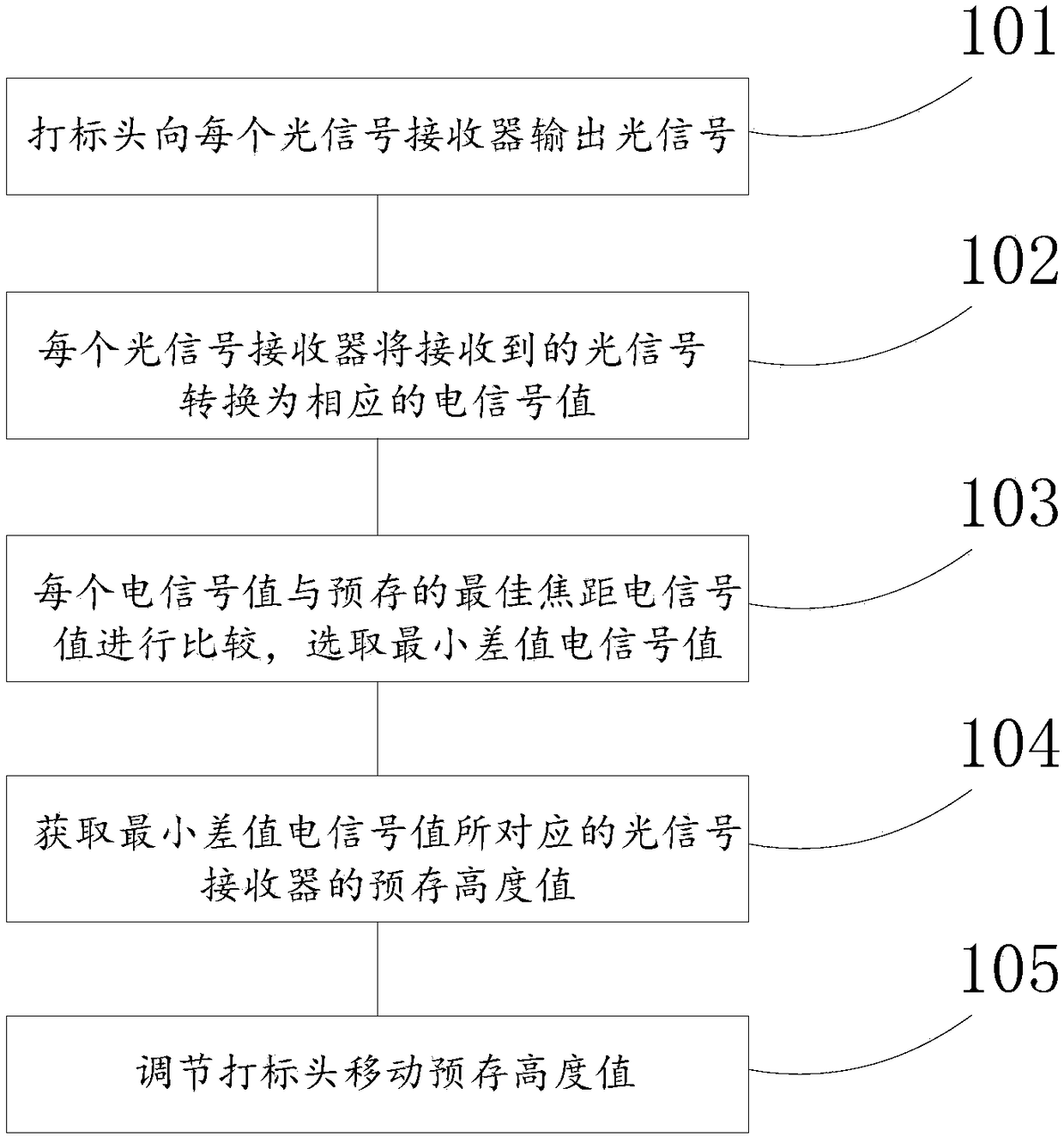

[0037] figure 1 A focusing method of a laser marking machine provided by an embodiment of the present invention. Wherein, the laser marking machine includes a marking head and a laser marking machine focusing device arranged under the marking head, and the laser marking machine focusing device includes a plurality of optical signal receivers corresponding to different pre-stored height values; the method includes :

[0038] Step S101: Adjust the marking head to the highest point, and the marking head outputs optical signals to each optical signal receiver; in practical applications, the optical signal receivers are arranged and installed step by step, that is, each optical signal The signal receivers are at different gradient heights, the marking head outputs laser light, and each optical signal receiver is marked one by one from the bottom along the slope of the ladder.

[0039] Step S102: Each optical signal receiver converts the received optical signal into a correspondin...

Embodiment 2

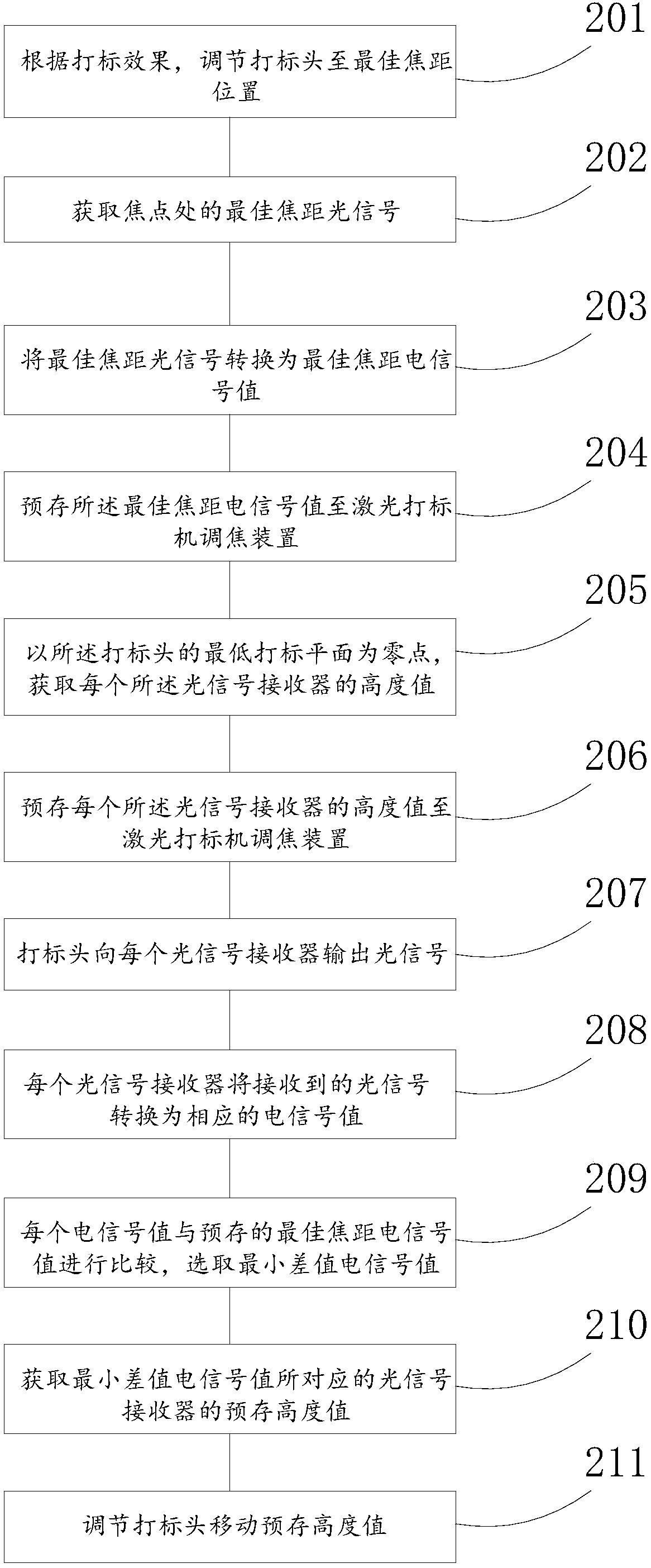

[0045] figure 2 Another laser marking machine focusing method provided by the embodiment of the present invention. The method includes:

[0046] Step S201: Put the workpiece on the workbench of the laser marking machine, perform trial marking on the workpiece, and adjust the marking head to the best focal length position according to the marking effect;

[0047] Step S202: Obtain the optical signal with the best focal length at the focal point; at this time, the height of the marking plane of the workpiece is the height of the focal point, and the intensity of the optical signal at the focal point is the optical signal with the optimal focal length.

[0048] Step S203: convert the best focal length optical signal into the best focal length electrical signal value; convert the intensity of the laser light signal at the focal point into an electrical signal value, and this electrical signal value is the best focal length electrical signal value, the electrical signal value Ca...

Embodiment 3

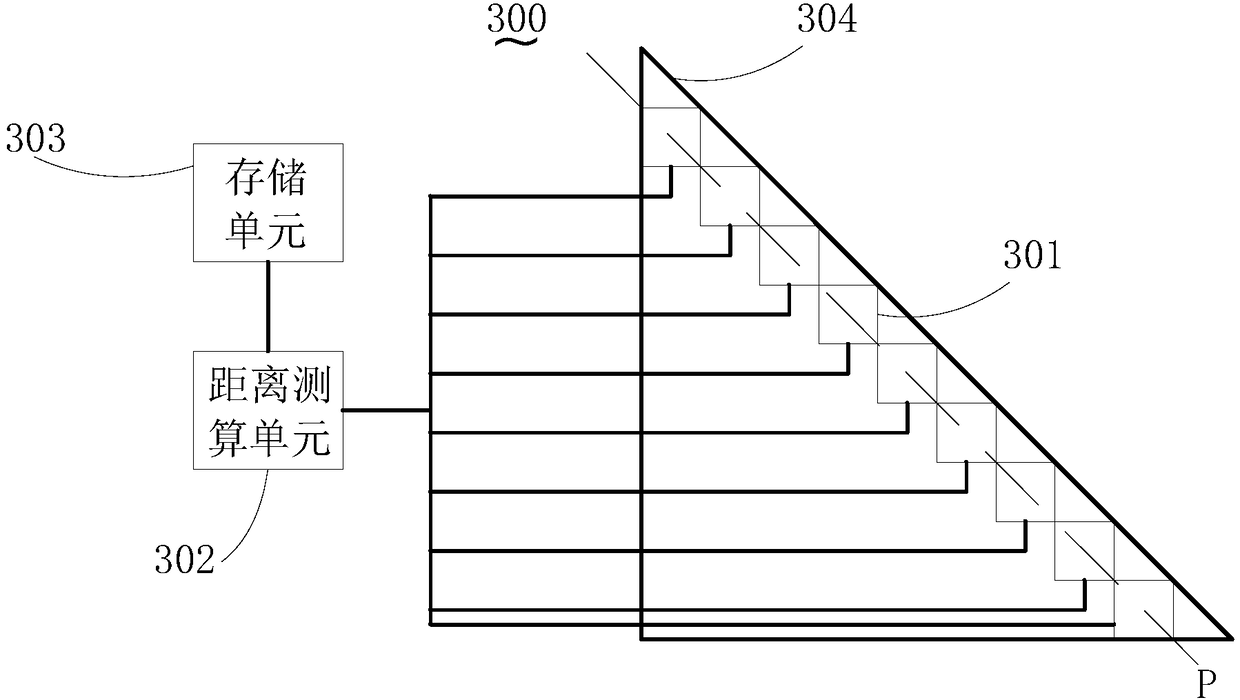

[0059] image 3 A focusing device for a laser marking machine provided by an embodiment of the present invention. The focusing device 300 of the laser marking machine includes: a base 304 , a plurality of optical signal receivers 301 , a distance measuring unit 302 and a storage unit 303 .

[0060] The base 304 is used for installing the optical signal receiver 301 . In this embodiment, the base 304 is a hollow triangular prism, and a plurality of optical signal receivers 301 can be installed on the base 304 by means of adhesion, welding or screw connection.

[0061] The optical signal receiver 301 is used to receive the optical signal from the laser marking machine. In practical applications, the optical signal receiver 301 may be a photoelectric sensor with a photoelectric signal conversion function, such as a photoresistor, a phototransistor, and the like. A plurality of optical signal receivers 301 are arranged and installed on the base 304 in a stepped manner along an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com