Wall climbing spraying robot based on mechanical arm

A technology of spraying robots and mechanical arms, which is applied in the direction of manipulators and manufacturing tools, which can solve the problems that the spraying effect is easily disturbed by human factors, the quality of the paint surface is different, and the labor intensity is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

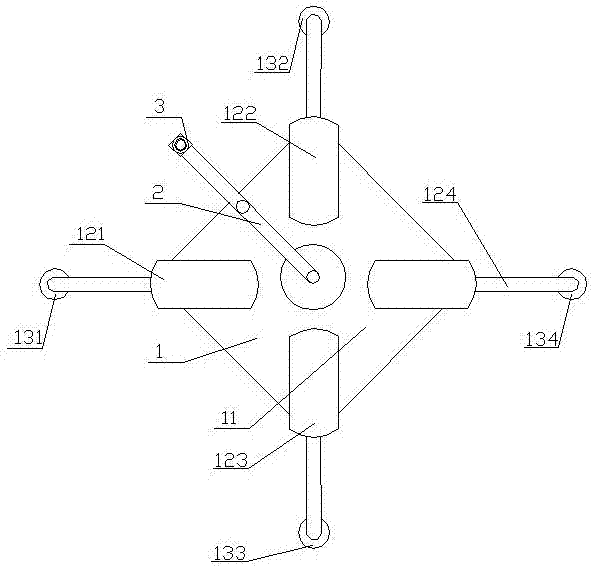

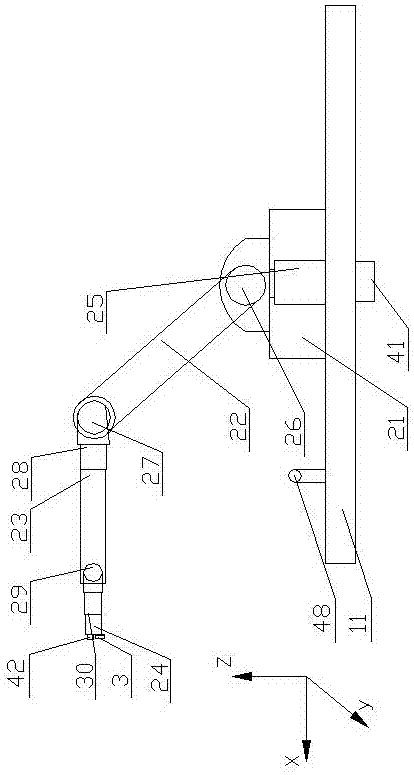

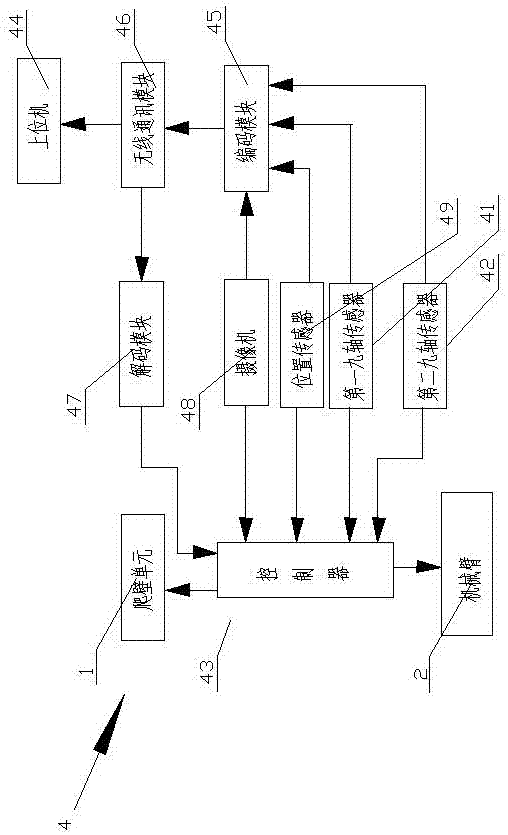

[0030] Such as figure 1 , 2 , 3, the present invention includes a climbing unit 1, a mechanical arm 2, a paint nozzle 3 and a control system 4.

[0031] The wall climbing unit 1 comprises a chassis 11, and the four corners of the chassis 11 are equipped with a first electric push rod 121, a second electric push rod 122, a third electric push rod 123 and a fourth electric push rod 124 arranged diagonally. The output end of the push rod 121 is connected with the first electromagnet 131, the output end of the second electric push rod 122 is connected with the second electromagnet 132, the output end of the third electric push rod 123 is connected with the third electromagnet 133, and the fourth electric push rod 123 is connected with the third electromagnet 133. The output end of the electric push rod 124 is connected with a fourth electromagnet 134 .

[0032] How crawling unit 1 works:

[0033] When moving up vertically, the first electromagnet 131 and the fourth electromagne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com