A prefabricated non-load-bearing reinforced concrete-aerated concrete composite wall panel

A reinforced concrete slab and reinforced concrete technology, applied to walls, manufacturing tools, building components, etc., can solve the problems of complex construction technology, easy cracking, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

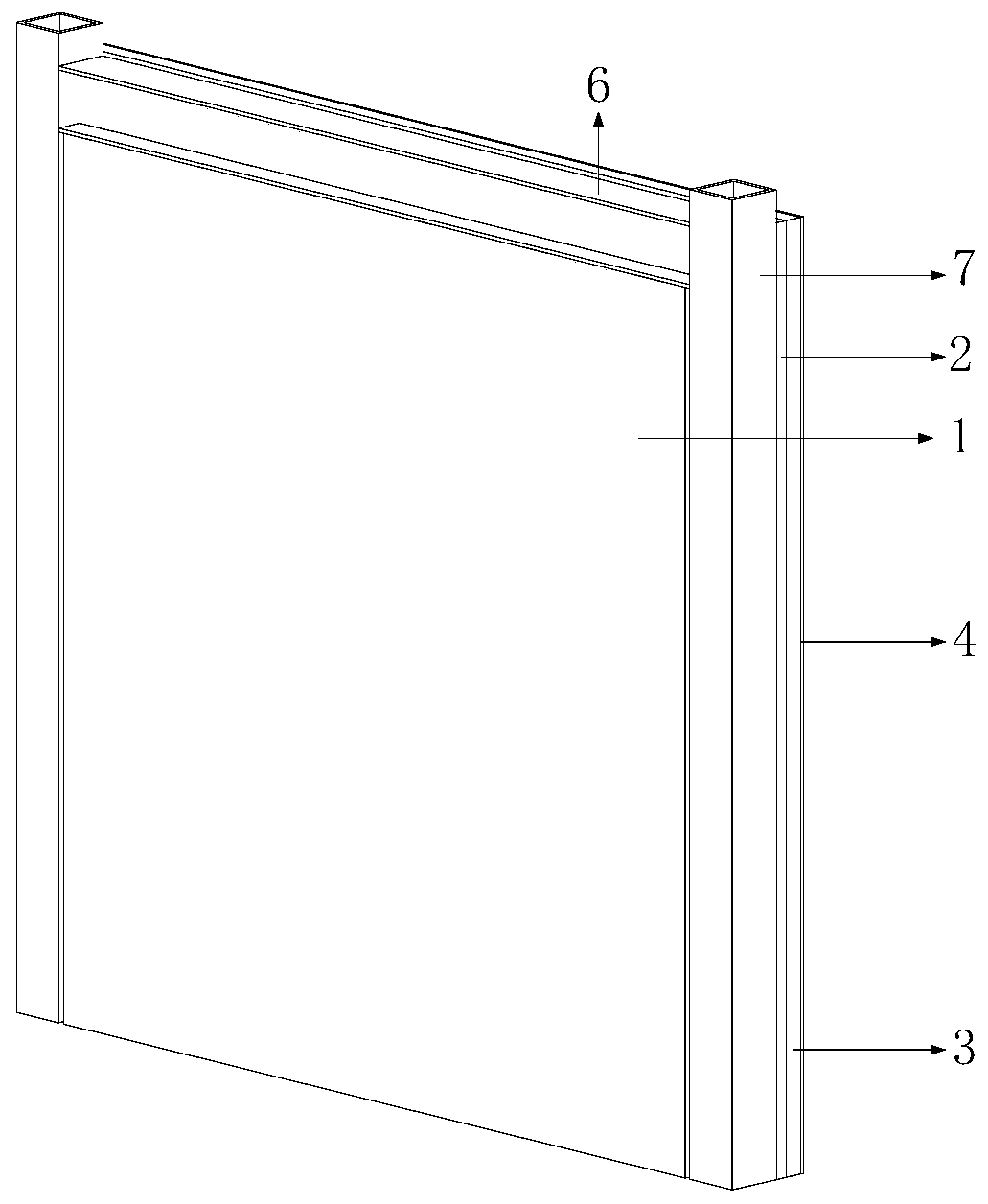

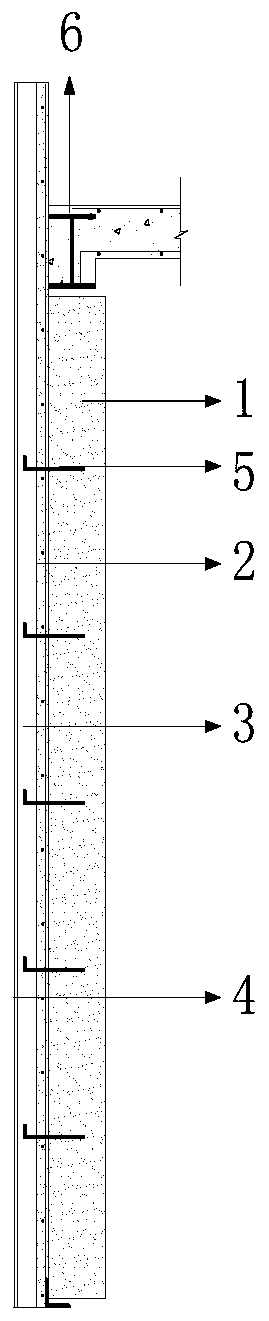

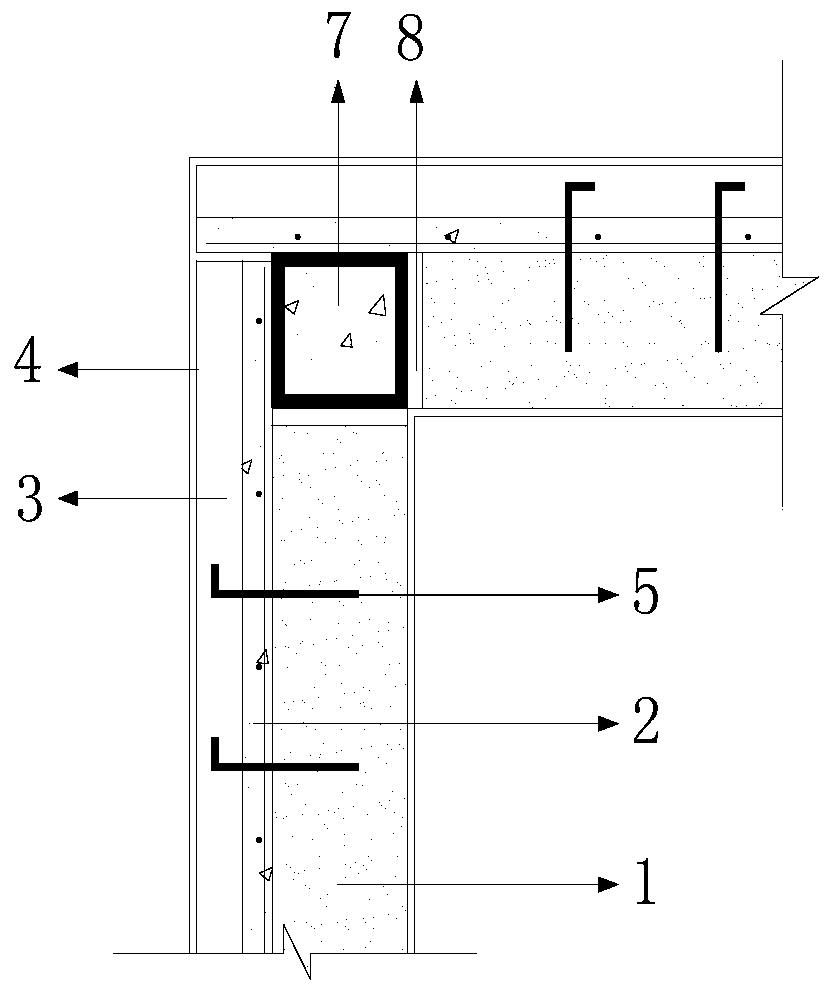

[0018] Such as figure 1 As shown, the prefabricated non-load-bearing reinforced concrete-air-entrained concrete composite wall consists of ALC board (1), reinforced concrete board (2), thermal insulation board (3), cement fiber concrete (4) and exterior wall paint in sequence from inside to outside To form, the inner side of the wall is coated with mortar and plastered, and the joints left are sealed with mortar (8).

[0019] A method for manufacturing an assembled prefabricated non-load-bearing ALC wall panel, comprising the following steps:

[0020] a. First, fly ash (or silica sand), cement, lime, etc. are used as the main raw materials in the factory, and processed into a porous ALC board (1) through high-pressure steam curing, and the preset connection bending ribs (5);

[0021] b. After the curing of the ALC (slab) is completed, the steel bars are bound together with the connecting bending bars (5) and concrete is poured, so as to process the reinforced concrete slab (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com