Novel passage inner panel sound absorption cotton

A sound-absorbing cotton and channel technology, applied in the field of sound-absorbing materials, can solve problems such as poor shockproof and heat insulation effects, difficulty in recycling sound-absorbing cotton corner waste, and unsatisfactory sound-absorbing effects, so as to increase the aesthetic feeling and be decorative Strong, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

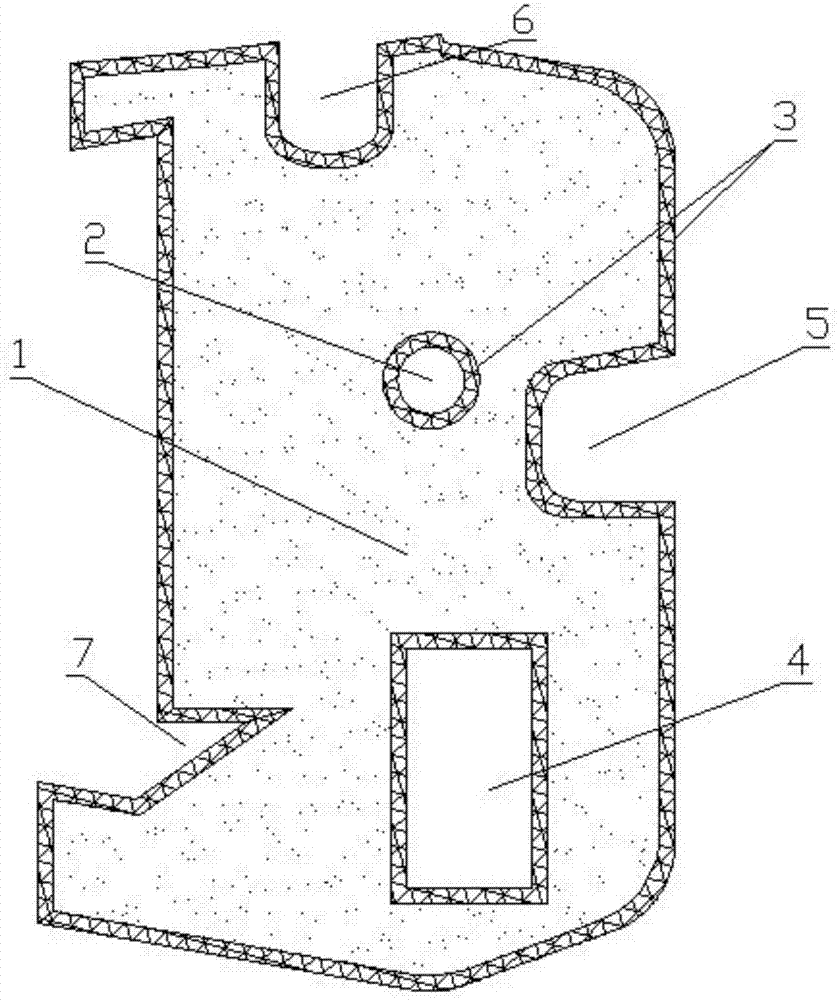

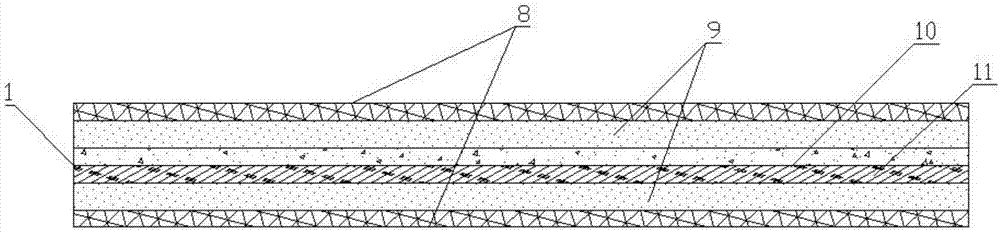

[0023] see Figure 1-2 As shown, the present invention provides a technical solution: a new type of channel inner panel sound-absorbing cotton, the channel inner panel sound-absorbing cotton includes cotton core 1, circular through hole 2, double-sided edge banding 3, square through hole 4, square Groove 5, round bottom groove 6, pointed groove 7, outer sound-absorbing layer 8, middle sound-absorbing layer 9, first sound-absorbing inner layer 10 and second sound-absorbing inner layer 11, the upper center of the cotton core 1 A circular through hole 2 is opened, and a square through hole 4 is opened in the lower part of the center of the cotton core 1. The outer edges of the cotton core 1, the circular through hole 2 and the square through hole 4 are designed as double-sided seals. Side 3, the upper right side of the cotton core 1 is provided with a square groove 5, the upper side of the cotton core 1 is provided with a round bottom groove 6, and the lower left side of the cott...

Embodiment 2

[0036] A new type of channel inner panel sound-absorbing cotton. The difference between this embodiment and Embodiment 1 is that the first sound-absorbing inner layer 10 is made by uniformly laying and pressing algae plant fibers.

[0037] The algae plants are squeezed and dried to obtain white algae plant fibers, which have the same excellent sound-absorbing function as the rubber sponge layer.

Embodiment 3

[0039] A new type of channel inner panel sound-absorbing cotton. The difference between this embodiment and Embodiment 1 is that the first sound-absorbing inner layer 10 is made of silicon rubber foam plastic material.

[0040] The silicone rubber plastic is dissolved into a liquid at high temperature and then cooled rapidly after passing through an inert gas. The interior contains a bubble structure to obtain a silicone rubber foam. The silicone rubber foam has the same excellent sound-absorbing function as the rubber sponge layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com