Cavity-type ventral wing connecting balanced suspension bracket

A balanced suspension and cavity-type technology, applied in the suspension, interconnection system, transportation and packaging, etc., can solve the problems of unreasonable connection structure and form, low generalization rate, low reliability, etc., and improve the utilization of materials The effect of high efficiency, low production cost and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further explained and illustrated below in the manner of specific embodiments.

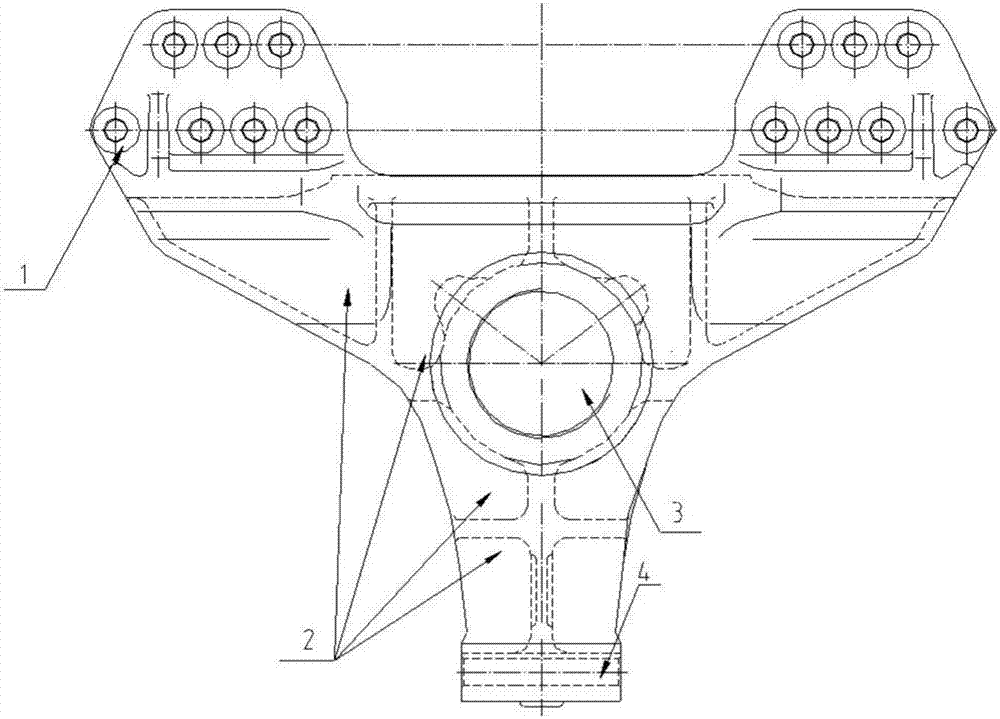

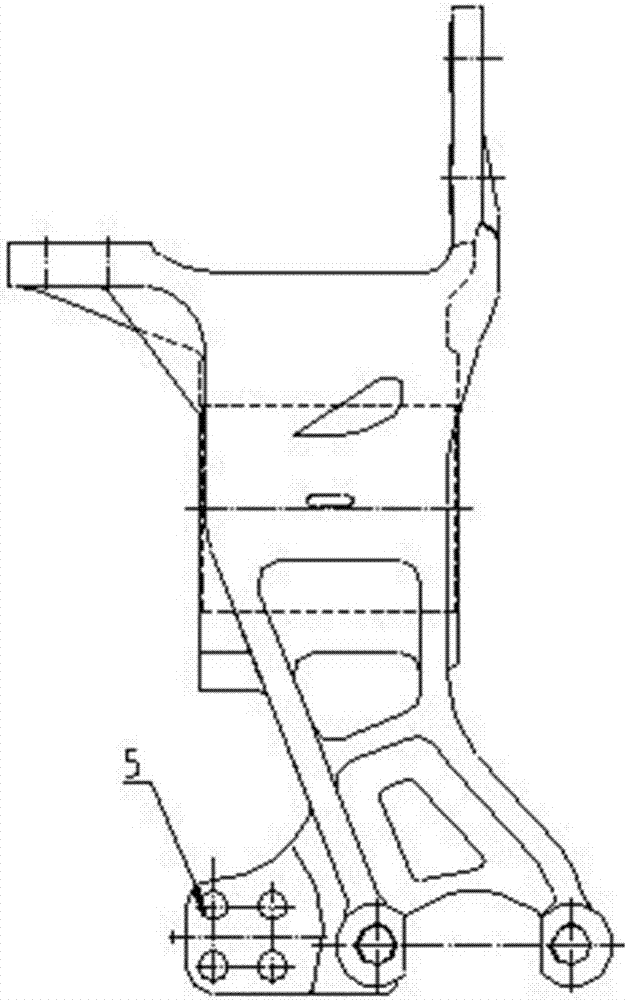

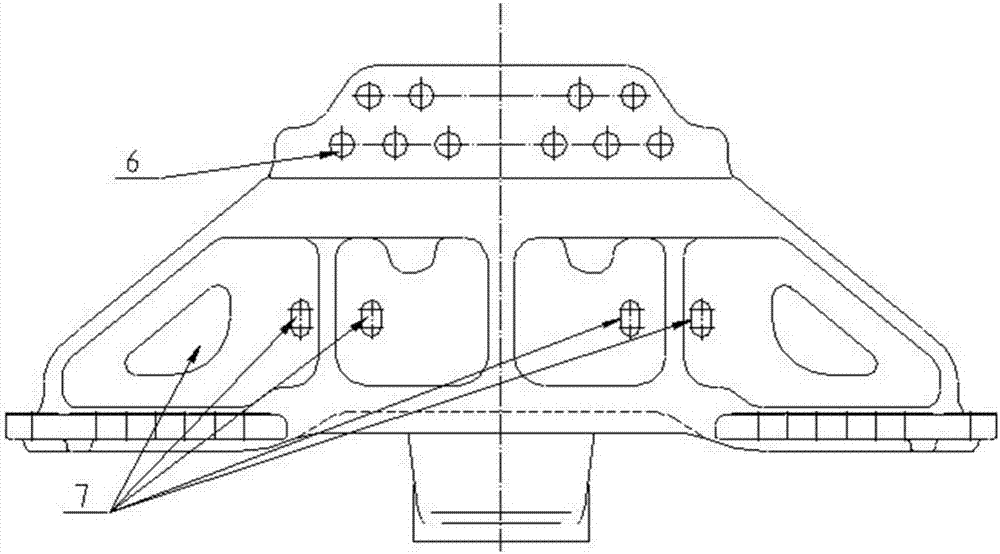

[0019] The bracket main body of the cavity-type belly wing connection balance suspension bracket in this embodiment is a box-shaped structure, and its outline is a triangle with a narrow top and a wide bottom. Two belly wings are arranged symmetrically on the upper part of the bracket main body. The main body of the bracket is connected, and a plurality of longitudinal beam connecting holes 1 are arranged on it; the connecting part of the frame beam extending outward is provided between the two abdominal wings on the upper part of the bracket main body, and the connecting part of the frame beam is provided with connecting holes for the frame beam 6. The middle part of the main body of the bracket is provided with a balance shaft matching hole 3, and the lower part of the main body of the bracket is provided with a connection end 4 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com