Split-type telescopic roller

A telescopic roller and split-type technology, which is applied in the field of textile rollers, can solve the problem that the length cannot be changed, and achieve the effect of structural optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

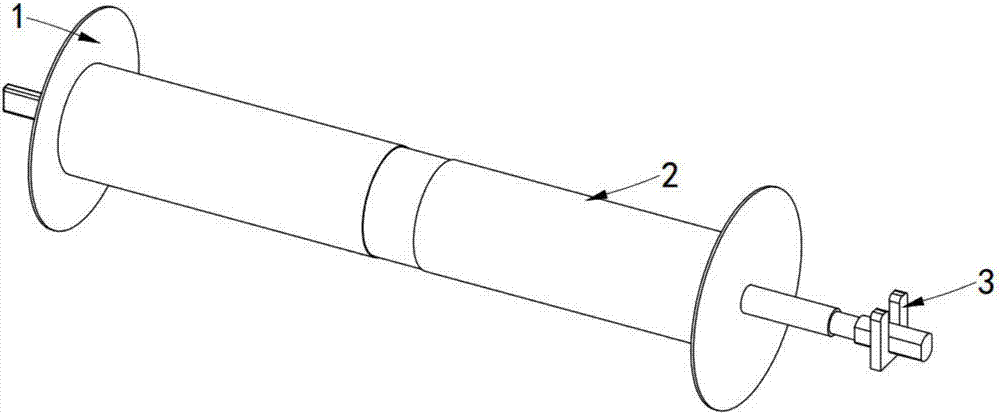

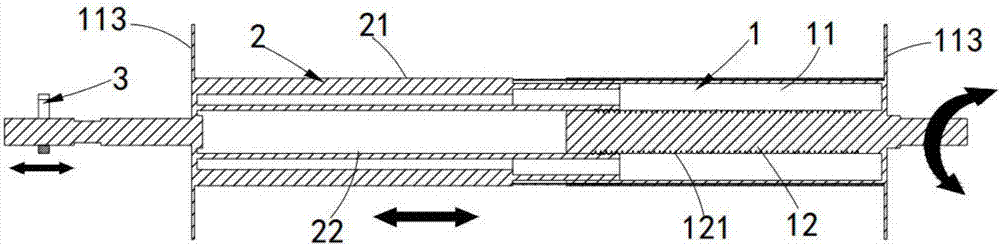

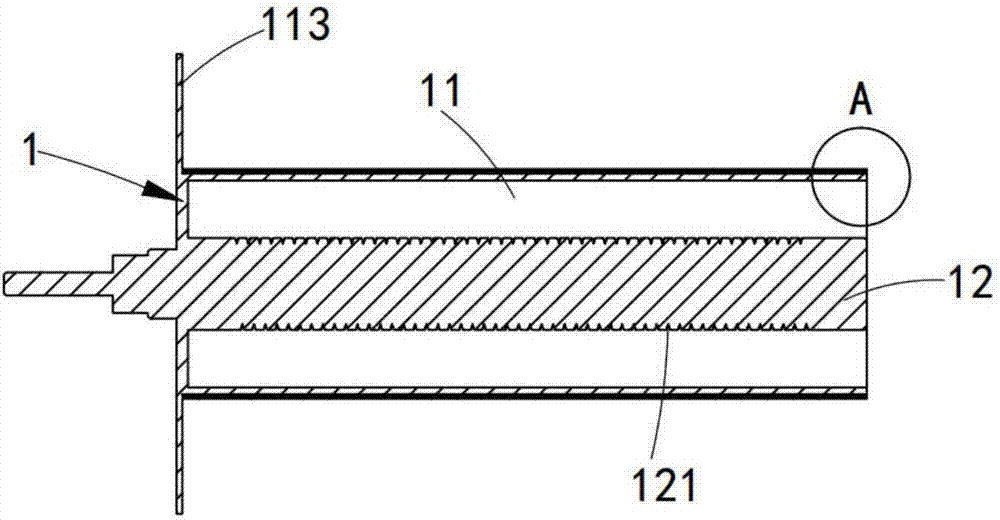

[0032] like figure 1 and figure 2 As shown, a split telescopic roller, including:

[0033] The first roller 1, the first roller 1 is cylindrical, which includes a first cylinder portion 11 and a first shaft portion 12, the first cylinder portion 11 is open at one end and hollow in the middle, and the first cylinder portion 11 is hollow. A shaft portion 12 is disposed at the center of the circle through the first cylindrical portion 11, and the first shaft portion 12 is solid;

[0034] The second roller 2, the second roller 2 is cylindrical, and it includes a second cylinder portion 21 and a second shaft portion 22, the second cylinder portion 21 is open at one end and hollow in the middle, and the second cylinder portion 21 is hollow. The second shaft part 22 is arranged at the center of the circle through the second cylinder part 21, and the second shaft part 22 is hollow;

[0035] The second cylinder portion 21 is concentrically slidably sleeved with the first cylinder p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com