Coal mine main shaft vertical shaft hoisting bucket safety start monitoring device and monitoring method

A monitoring device and safe start technology, applied in the direction of lifting equipment, elevators, transportation and packaging in mines, can solve the problem of difficulty in judging whether there are maintenance workers around the skip, large installation costs and operational burden, identification efficiency and reliability. low problems, to achieve the effect of safe operation, low cost, reliable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

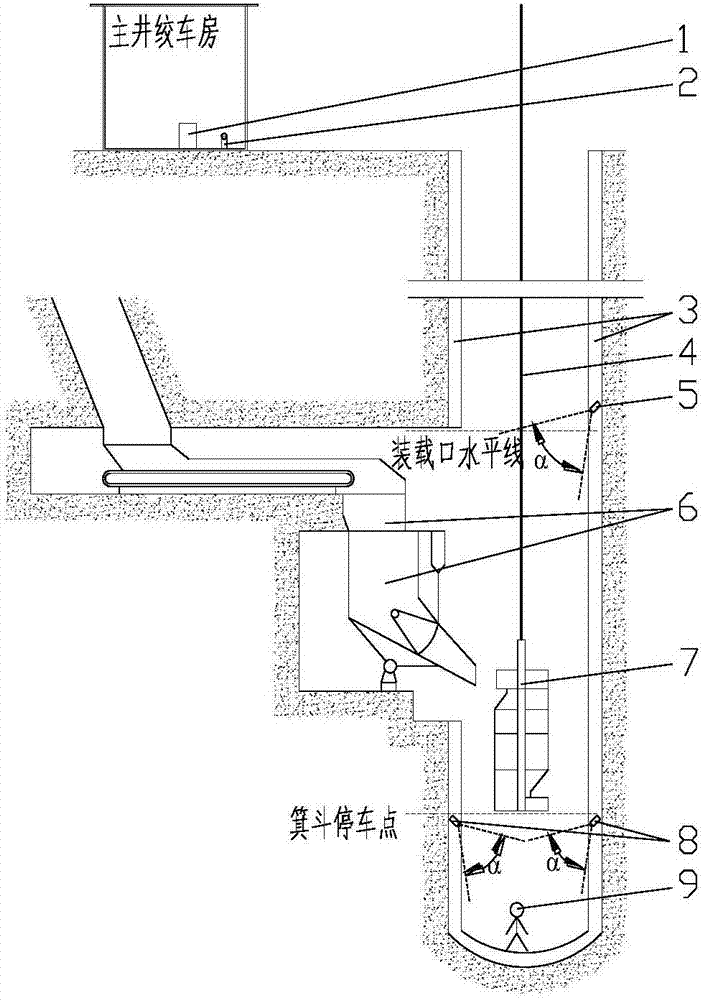

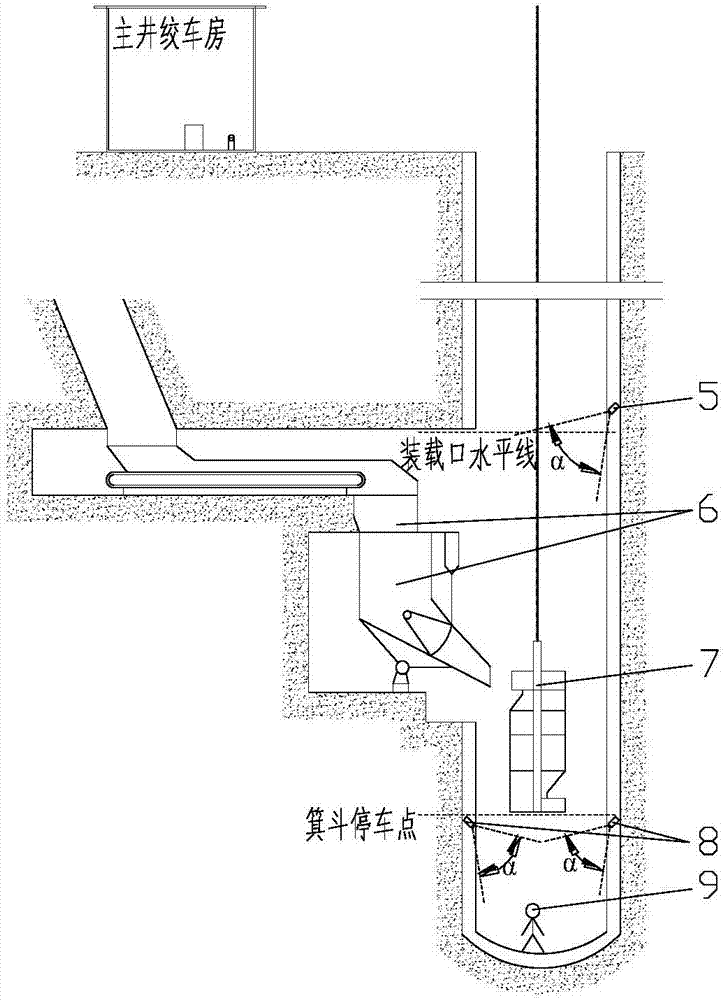

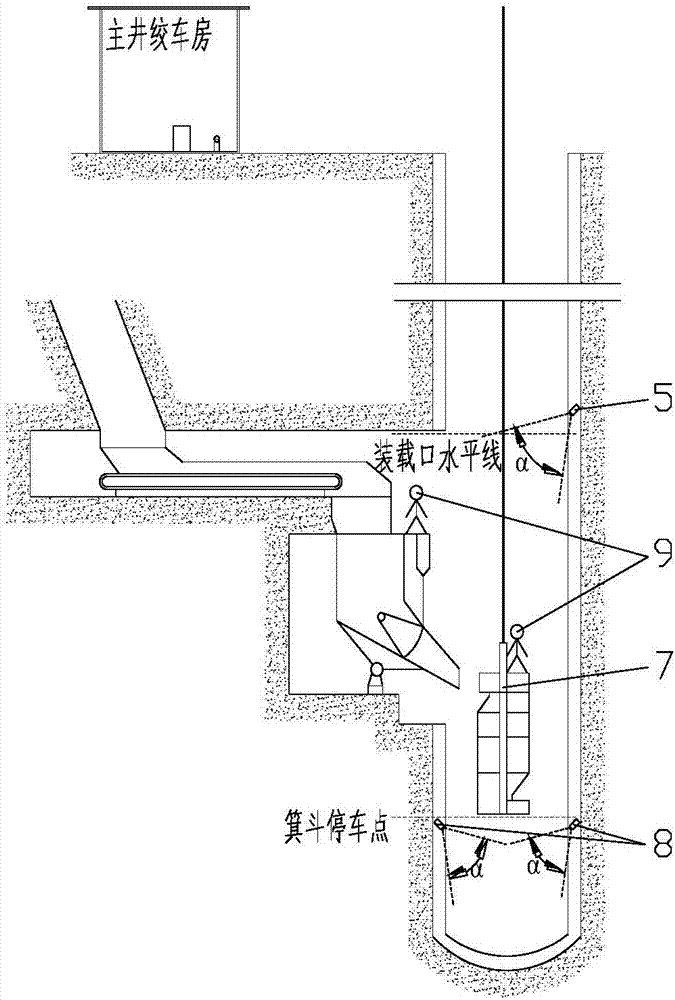

[0025] Such as figure 1 , figure 2 with image 3 Shown is a coal mine main shaft hoist skip safety start monitoring device, mainly including infrared camera group I8, infrared camera II5, signal processor 1 and sound and light alarm 2; the two cameras of infrared camera group I8 are arranged oppositely, The two cameras are set at the same height and slightly lower than the stop point of the skip, and the lenses of the two cameras face the bottom of the skip 7 to photograph the bottom of the skip 7. Bottom well image at the bottom of the bucket 7; the infrared camera II5 is set on the non-coal-feeding side of the main shaft derrick 3 and slightly higher than the loading port. The image on the top of the skip 7; the signal processor 1 is set in the winch house of the main shaft, and communicates with the infrared camera group Ⅰ 8, the infrared camera Ⅱ 5 and the soun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com