Circle cutter for glass product machining

A glass product and glass technology, which is applied in the field of circular cutters for glass product processing, can solve the problems of low cutting efficiency, inability to cut circular glass of different sizes, and inability to move the cutting mechanism, and achieves the effect of high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

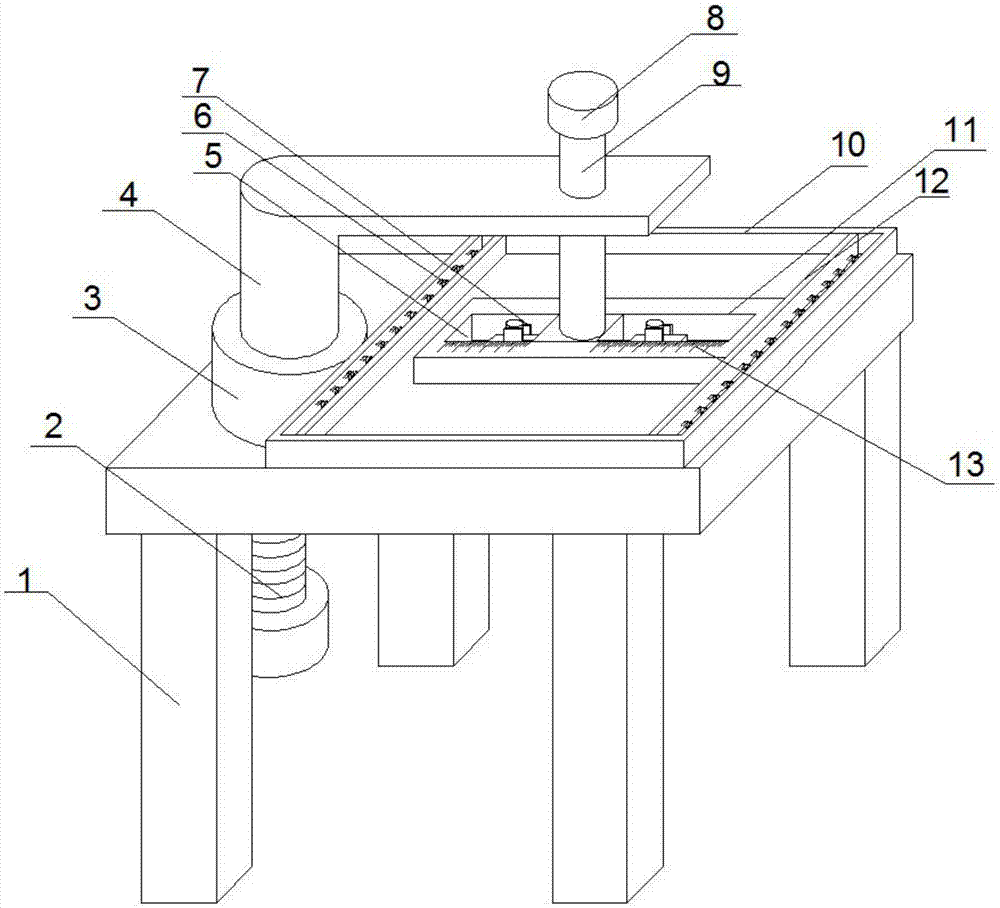

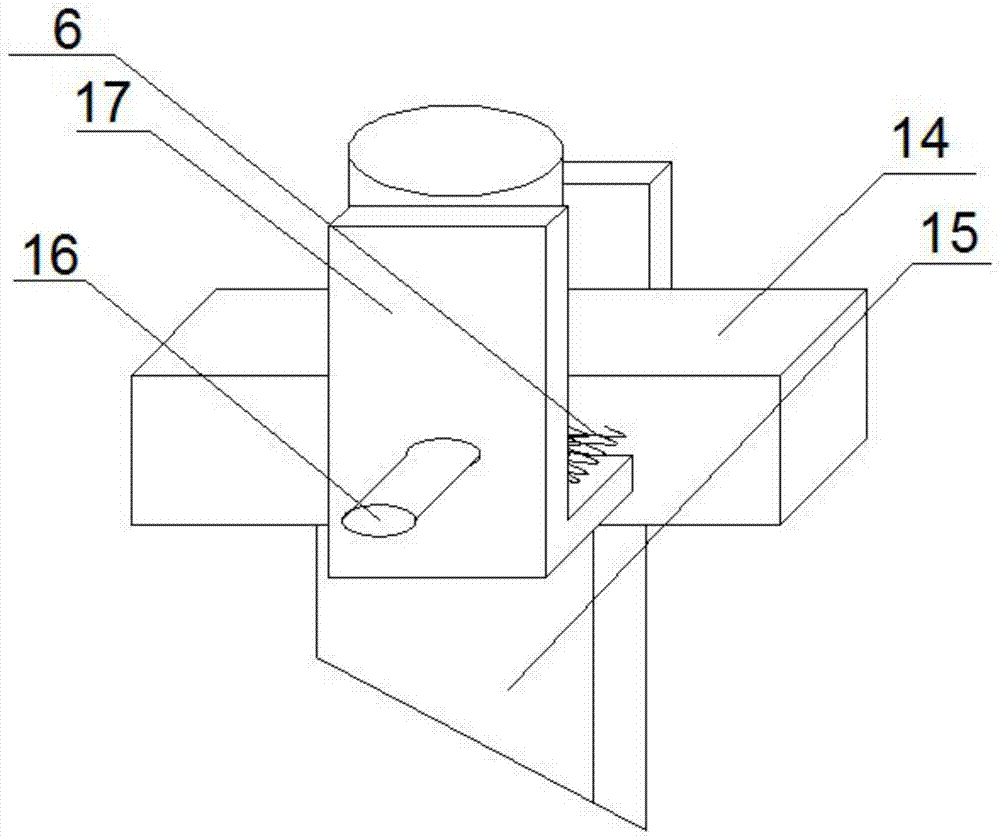

[0016] Such as figure 1 with 2 As shown, this embodiment provides a circle cutter for processing glass products, including a frame, the frame is provided with a base, the base is provided with a liftable support, and the support is provided with a motor-driven The rotating shaft, the end of the rotating shaft is fixed with a mounting plate, and two mounting grooves are symmetrically opened on the mounting plate, and a slidable cutting mechanism is installed in the mounting groove, the two cutting mechanisms work at the same time, and the cutting efficiency is high , and round glass of different sizes can be cut according to needs.

[0017] Further, the bracket is driven by a screw screwed in the base and in contact with the bottom of the bracket...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap