Pipeline corridor construction structure crossing track shield interval

A technology of shield tunneling area and pipe gallery, which is applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve the problems of inapplicability and large structural deformation in the track section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

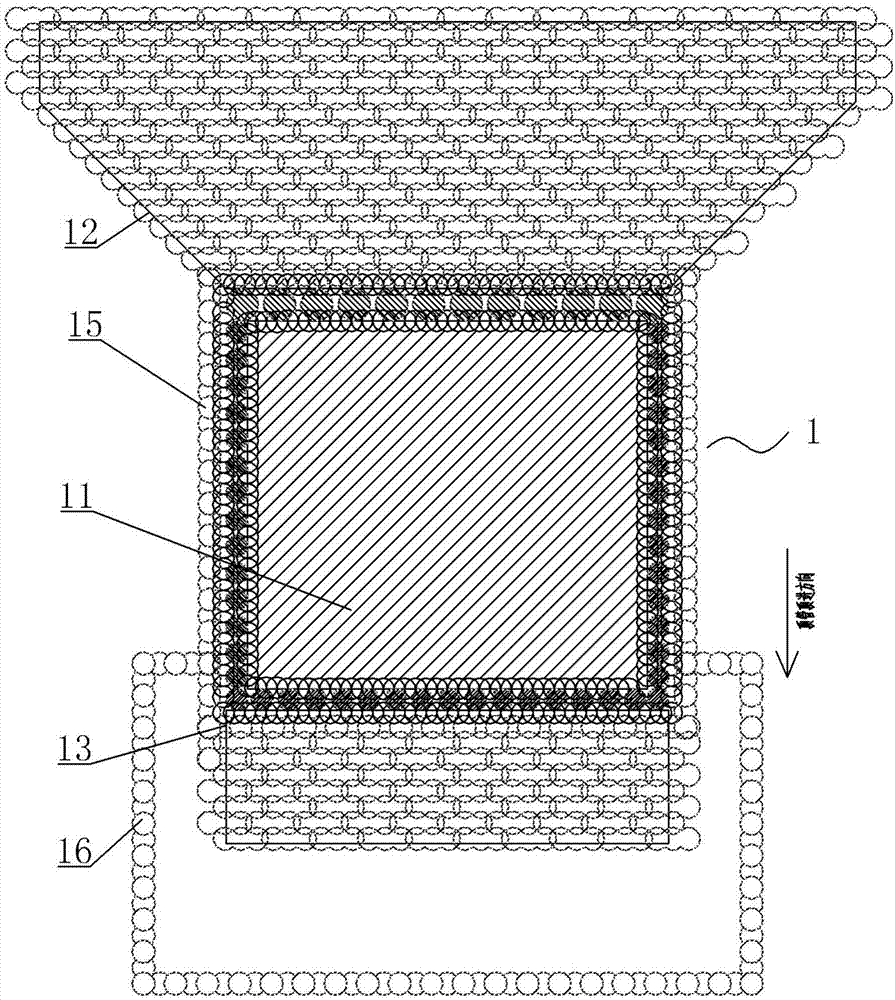

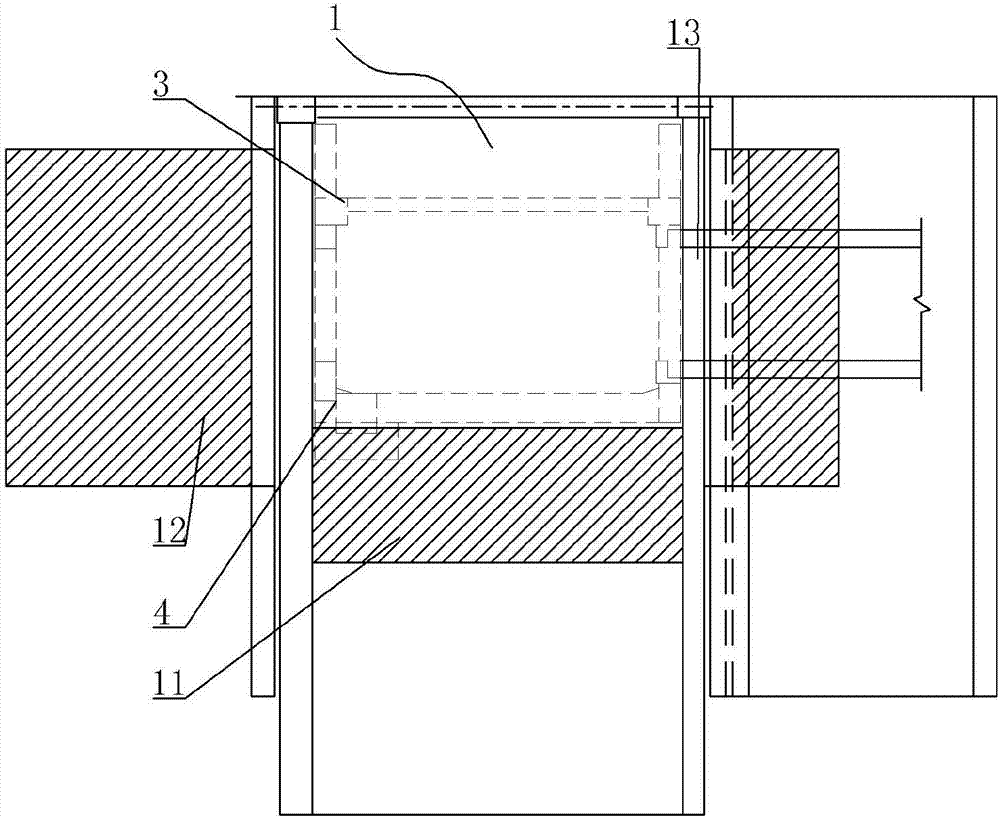

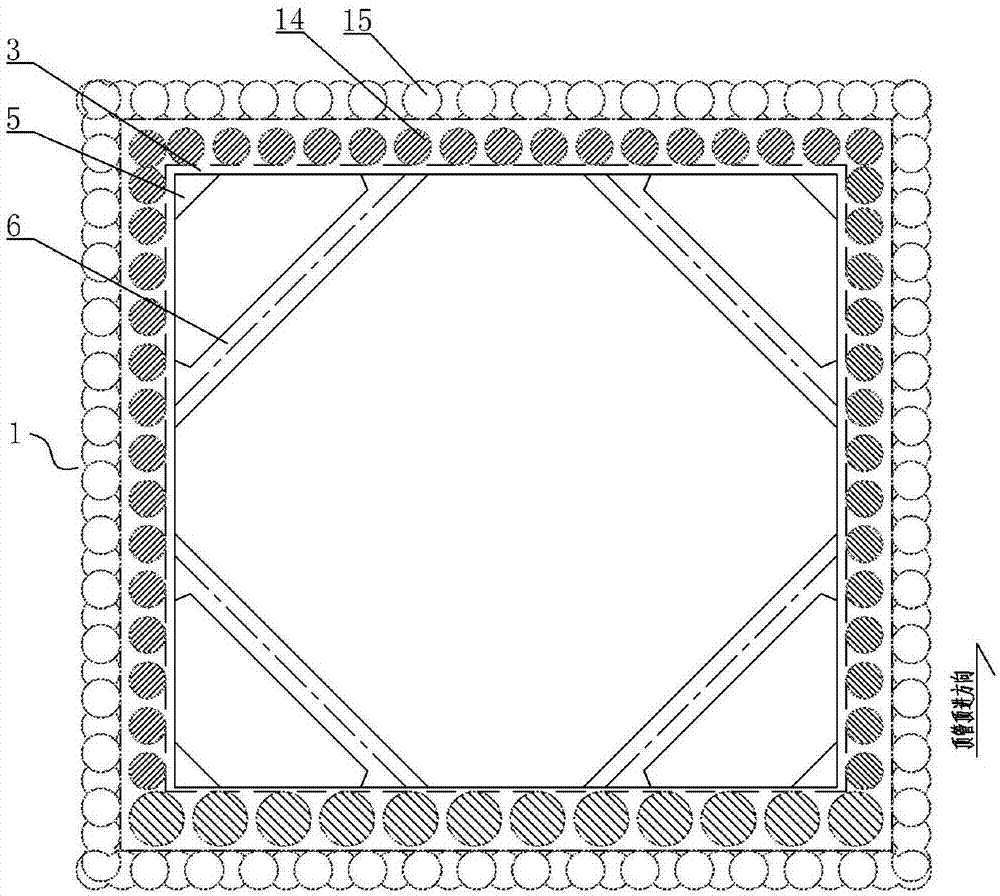

[0025] A pipe gallery construction structure spanning the shield section of the track, see Figure 1-8 : It includes the construction well and the pipe gallery channel between two adjacent construction wells. The layout distance of the construction well is far away from the track section. Well 1, several receiving wells 2, the originating shaft 1 is used to initially locate the position of the pipe gallery, the receiving well 2 is used for gradual positioning during the excavation process of the pipe gallery, the bottom pit 11 of the originating shaft 1 is reinforced, and the originating shaft The backrest 12 foundation of the well 1 is reinforced, the outlet 13 foundation of the originating shaft 1 is reinforced, the side wall of the originating shaft 1 is provided with a first bored pile enclosure 14, and the outer side of the first bored pile enclosure 14 is arranged with The first three-axis mixing pile water-stop curtain 15, the bottom pit 21 of the receiving well 2 is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com