Deep soft soil roadbed composite structure and construction method

A soft soil roadbed and composite structure technology, which is applied in basic structure engineering, roads, roads, etc., can solve the problem of poor treatment effect of deep soft soil layer, single treatment method, and can not guarantee the overall stability of deep soft soil roadbed. and other problems to achieve the effect of reducing structural deformation, improving durability and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

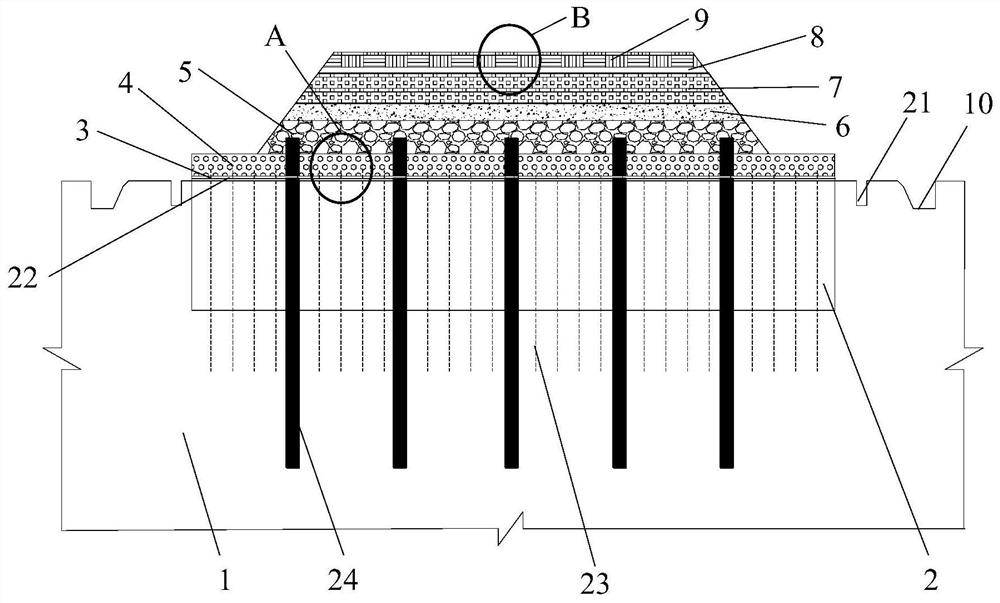

[0065] A composite structure of deep soft soil subgrade, which comprehensively adopts the principle and technology of dynamic consolidation drainage, rigid support and flexible composite material panel, and effectively improves the bearing capacity and stability of the soft soil subgrade structure. The specific form of a deep soft soil subgrade composite structure will be described in detail below in conjunction with the accompanying drawings.

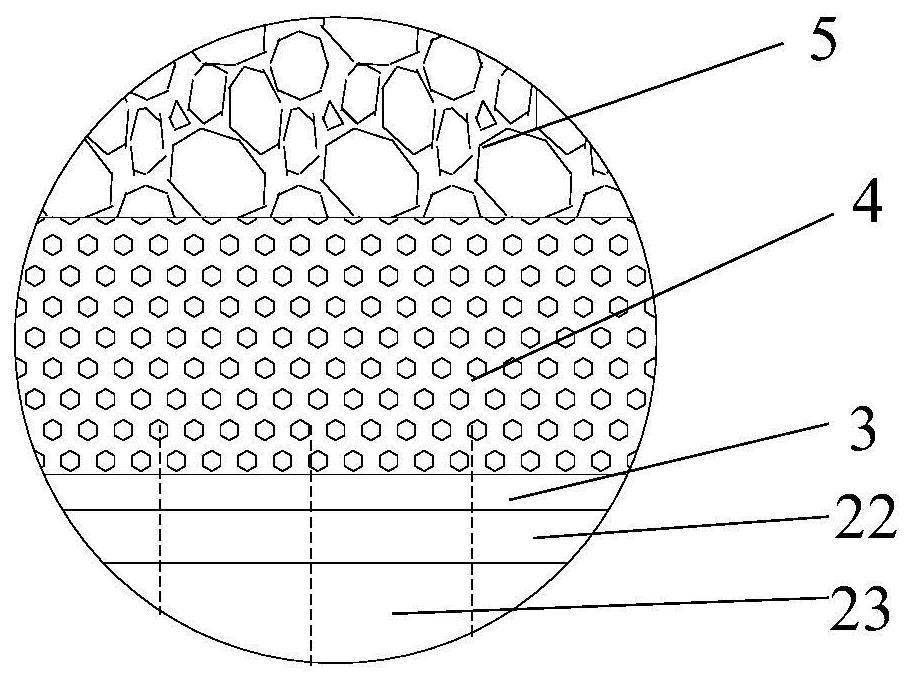

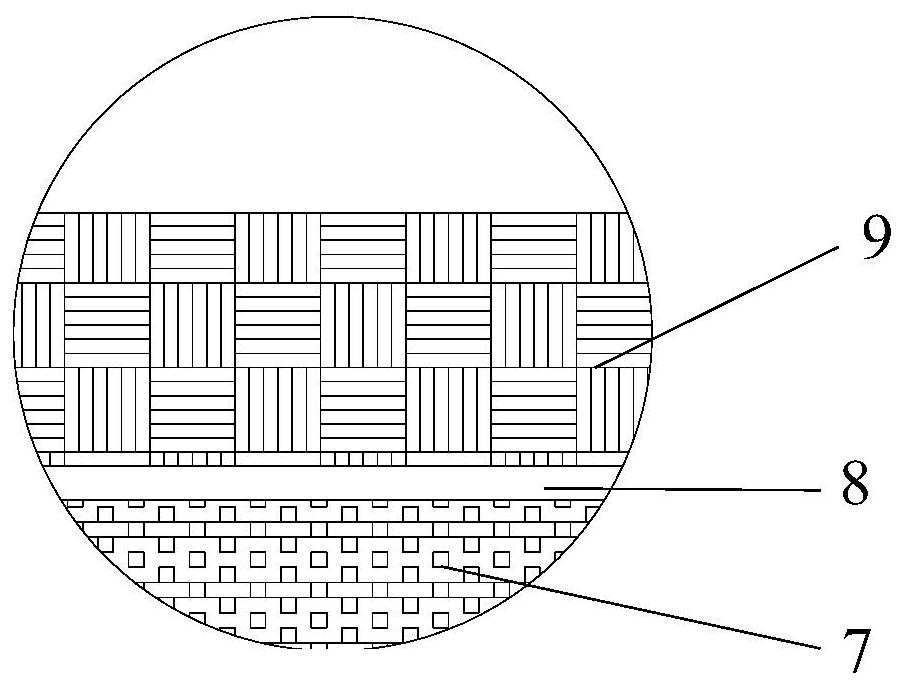

[0066] Such as figure 1 As shown, a composite structure of a deep soft soil subgrade consists of the first soft soil layer 1, the second soft soil layer 2, the geotextile 3, the crushed stone cushion 4, the block stone layer 5, and the sandstone cushion from bottom to top. 6. Cement stabilized crushed stone layer 7. Cement mortar bonding layer 8. Surface layer composite material board 9. Drainage blind ditches 21 and water collection wells 22 are arranged on the second soft soil layer 2 , and drainage boards 23 and micro piles 24 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com