Steel-wood composite beam component and production method

A manufacturing method and technology of composite beams, applied in the field of wood engineering, can solve the problems of few documents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

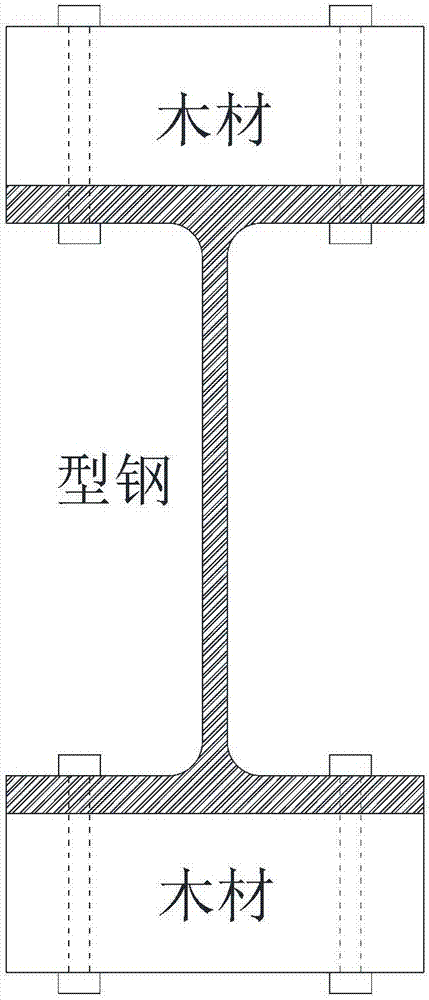

[0028] Combine below figure 1 , take a steel-wood composite beam as an example to further illustrate the present invention.

[0029] The structure of steel-wood composite beam members is as follows.

[0030] 1. The moisture content of the wood material is 12%.

[0031] 2. The wood material is fir sawn timber, the cross-sectional size of the sawn timber is 38*139mm, and the length is 6m.

[0032] 3. The section steel used is hot-rolled H-section steel, the cross-sectional size of H-section steel is 200mm*150mm, and the length is 6m.

[0033] 4. figure 1 The steel-wood composite beam shown is a steel-wood composite beam with wooden materials connected on both sides.

[0034] The technological steps of the steel-wood composite beam are as follows.

[0035] 1. Preparation of wooden materials:

[0036] Wood material is SPF lumber, dried to 12% moisture content.

[0037] 2. Preparation of section steel:

[0038] The section steel used is hot-rolled H-section steel, the cross...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com