Yaw brake mechanism of wind driven generator

A wind turbine, yaw braking technology, applied in wind turbines, wind turbine control, wind turbine monitoring and other directions, can solve problems such as not being able to be discovered in time, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

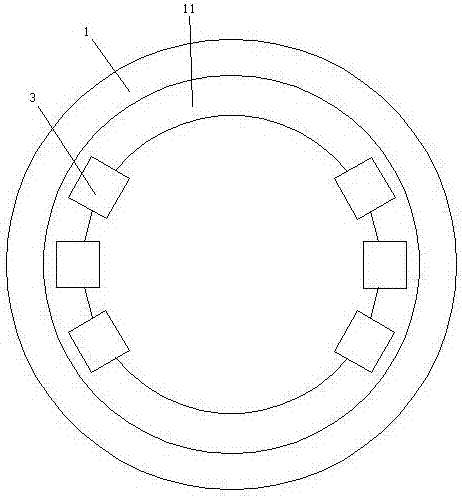

[0020] see figure 1 , a wind turbine yaw brake mechanism, including a yaw bearing 1, a brake ring 11 arranged on the yaw bearing and several brake units 3.

[0021] There are 6 brake units 3. Three of the six brake units 3 are arranged on the front side of the brake ring 11 , and the other three brake units 3 are arranged on the rear side of the brake ring 11 .

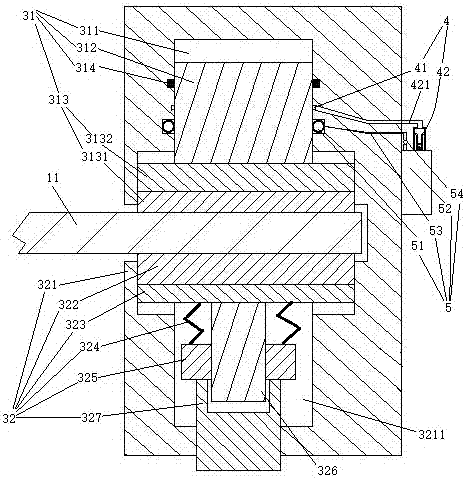

[0022] see figure 2 , The brake unit 3 includes a hydraulic brake 31 and a spring brake 32 . The hydraulic brake 31 is provided with a leakage detection mechanism 4 and a dynamic sealing ring 5 .

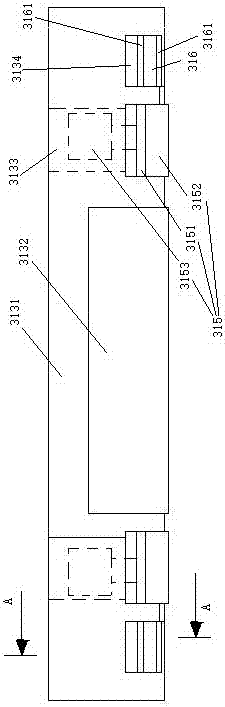

[0023] The hydraulic brake 31 includes a brake cylinder 311 , a piston 312 and a friction plate 313 of a hydraulic brake part. The hydraulic braking part friction plate 313 includes a mounting part 3131 and a friction part 3132 . The friction part 3132 is connected to one side of the mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com