Triaxial modularized dry type vacuum pump

A technology of dry vacuum pump and shaft module, applied in the direction of rotary piston pumps, pumps, rotary piston/swing piston pump components, etc., can solve problems such as dead angle, corrosion, equipment failure, etc., and achieve short distance and high energy consumption , the effect of air flow straight through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the technical solution of this embodiment will be described in detail below in conjunction with the accompanying drawings. The following embodiments are only used to illustrate the technical solution of this embodiment more clearly, so they are only examples, and should not be used to limit the protection scope of this embodiment.

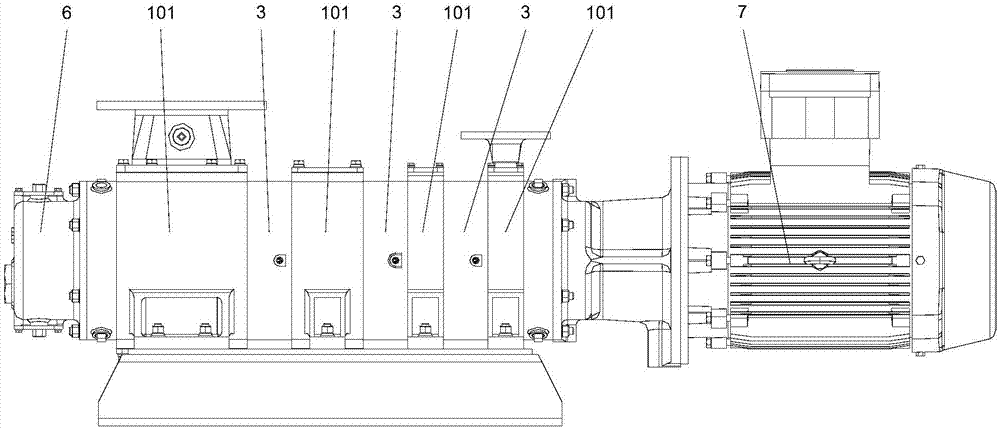

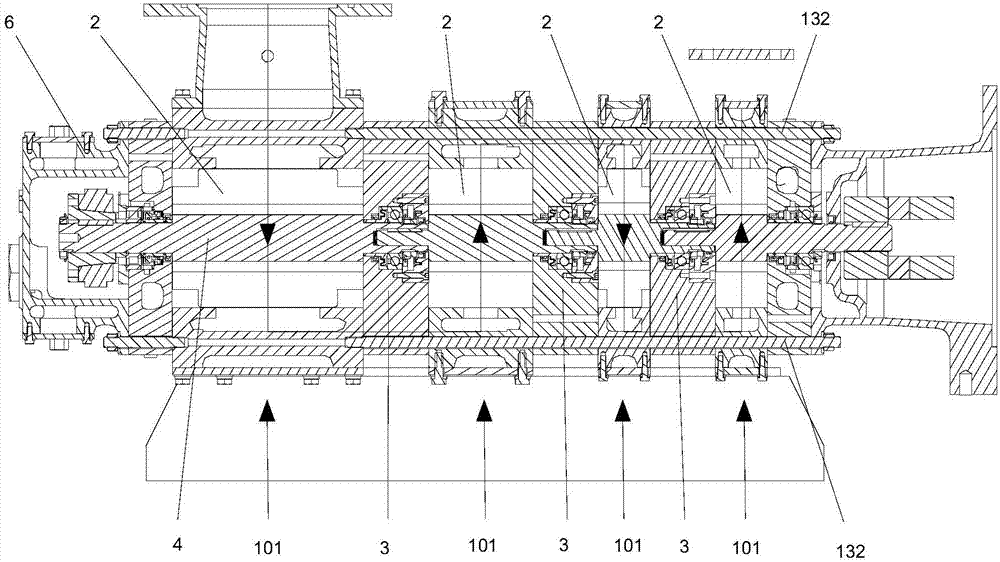

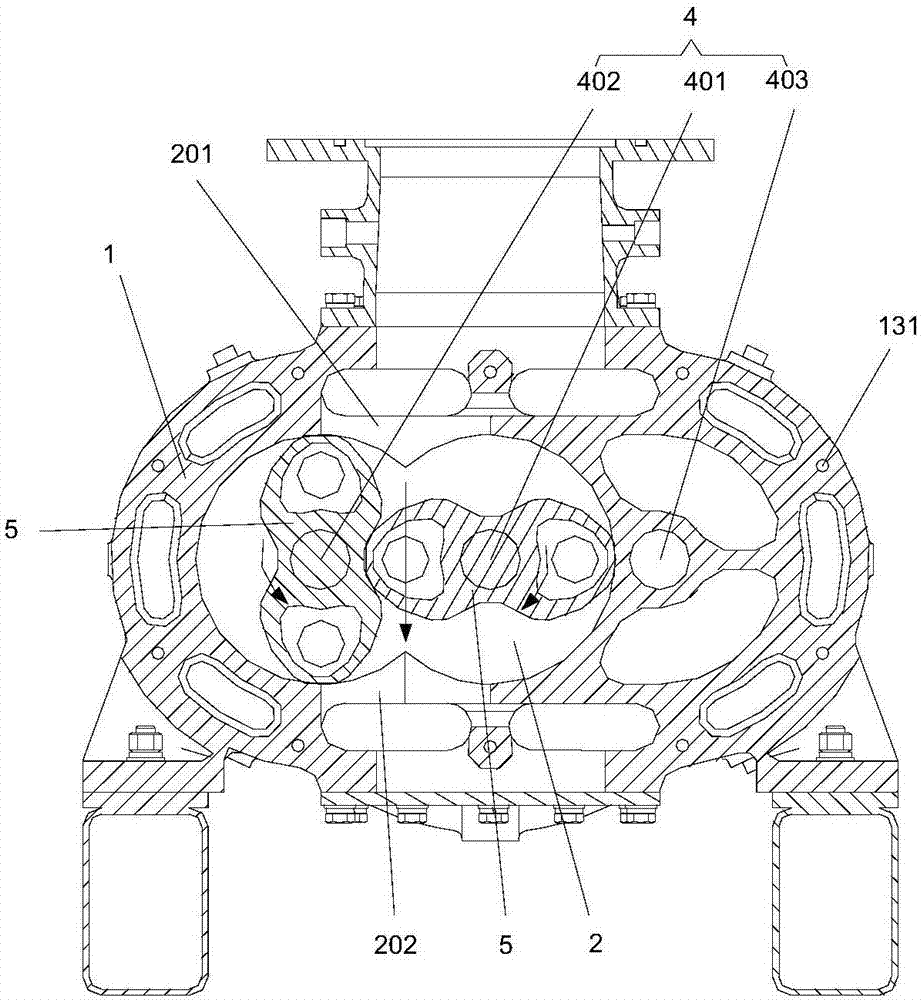

[0032] Such as Figure 1-Figure 7 As shown, the present invention provides a three-axis modular dry vacuum pump, which includes a pump body 1, and the pump body 1 is composed of multi-stage pump body units 101 in series, and each stage of the pump body unit 101 is correspondingly provided with a first-stage pump chamber 2 , Adjacent pump body units 101 are connected by partitions 3 , and the pump chambers 2 are separated by partitions 3 .

[0033] refer to Figure 2-Figure 4 One side of each pump chamber 2 is provided with a suction port 201, and the other side of each pump chamber 2 is provided with a discharge port 202. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com