Rotary reversing valve

A technology of rotating reversing valve and spool, applied in sliding valve, multi-port valve, valve device, etc., can solve the problems of not being suitable for low-cost production and rapid use, unable to realize oil circuit reversing, and high requirements for oil circuit connection , to achieve the effect of facilitating rapid production, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

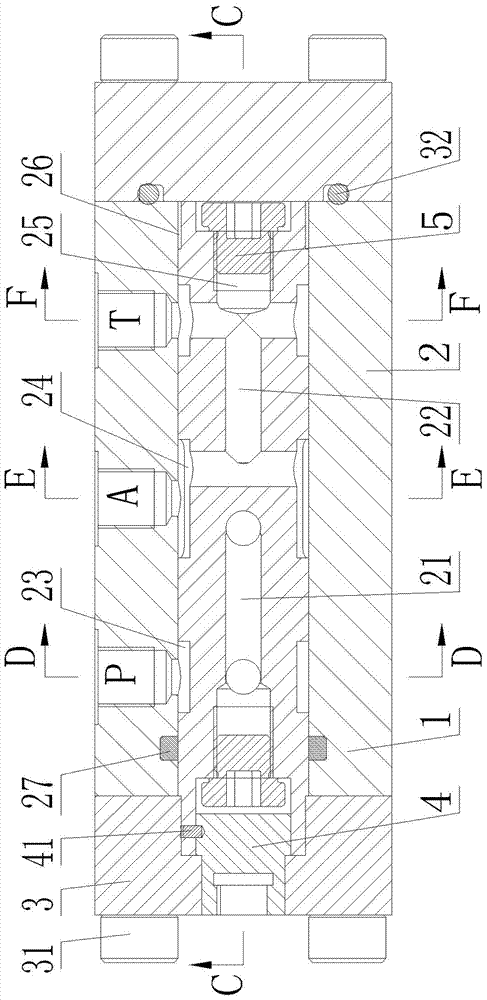

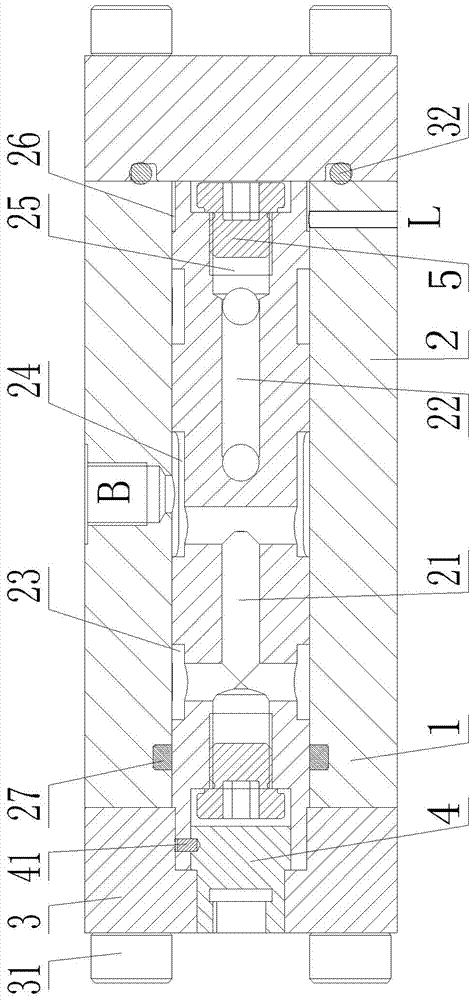

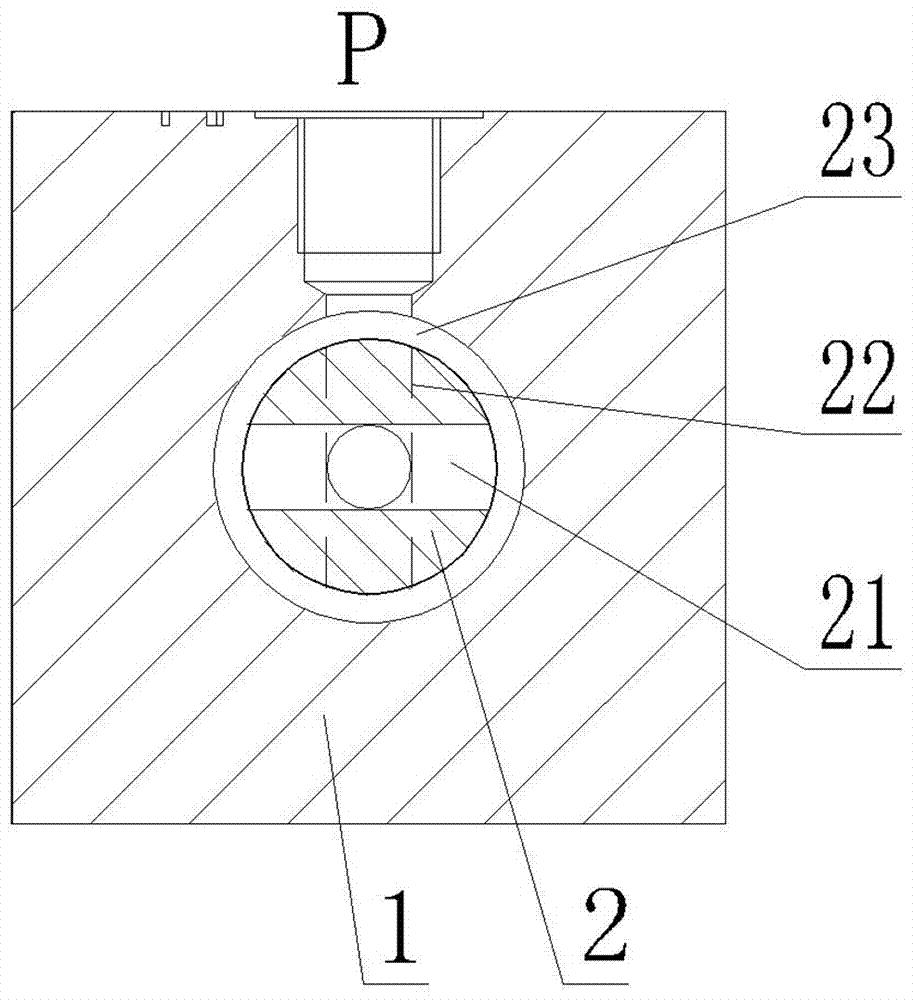

[0040] Taking the two-position four-way reversing valve as an example, from Figure 1 to Figure 5 It can be seen that the cross section of the valve body 1 of the present invention is square, and the working oil ports include oil port A and oil port B, and the oil port A and the oil port B are arranged on the center of the adjacent side walls of the valve body 1 and on the valve body 1. If the cross section is arranged at an included angle of 90°, there are two oil inlet passages 21 arranged symmetrically on the spool 2. The two oil inlet passages 21 share the blind hole 25 at the left end of the spool 2 on the longitudinal section of the spool. Two oil outlet passages 22 are symmetrically arranged on the valve core 2. The blind hole 25 at the right end of the common valve core 2 of the two oil outlet passages 22 is H-shaped on the longitudinal section of the valve core. The oil inlet passage 21 and the oil outlet passage 22 on the cross-section of the spool 2 are alternately ...

Embodiment 2

[0050] Take the three-position five-way reversing valve as an example, from Figure 6 to Figure 9 It can be seen that the cross section of the valve body 1 of the present invention is circular, and the working oil ports include the oil port A1, the oil port B1 and the oil port A2 arranged at an angle of 60° on the cross section of the valve body, and the oil inlet channel 21 There are two and symmetrically arranged on the spool 2, and the blind hole 25 at the left end of the common spool 2 of the two oil inlet passages 21 is H-shaped on the longitudinal section of the spool, and there are two oil outlet passages 22, which are symmetrically arranged on the spool 2 Above, the blind hole 25 at the right end of the common spool 2 of the two oil outlet passages 22 is H-shaped on the longitudinal section of the spool, and the oil inlet passage 21 and the oil outlet passage 22 are arranged at an angle of 60° on the cross section of the spool 2, There are four grooves 24 and they comm...

Embodiment 3

[0062] Take the two-position five-way reversing valve as an example, from Figure 10 to Figure 13 It can be seen that the working oil port of the present invention includes the oil port A3, the oil port B3 and the oil port A4 which are successively arranged at an angle of 60° on the cross section of the valve body, and there are three oil inlet passages 21 arranged in an annular array on the On the spool 2, three oil inlet passages 21 share the blind hole 25 at the left end of the spool 2, three oil outlet passages 22 are arranged on the spool 2 in an annular array, and the three oil outlet passages 22 share the blind hole 25 at the right end of the spool 2. The holes 25, the oil inlet passages 21 and the oil outlet passages 22 are arranged alternately at an angle of 60° on the cross section of the valve core 2, and there are six grooves 24 which communicate with the oil inlet passages 21 and the oil outlet passages 22 respectively. .

[0063] The rotation commutation process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com