Limited slip differential assembly

A technology of limited-slip differentials and differentials, which is applied to differential transmissions, belts/chains/gears, mechanical equipment, etc., and can solve problems such as unstable structures, poor performance in adjusting torque, and poor adhesion. Achieve good safety and stability performance, simple structure, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments. It should be understood that the examples are only for explaining the present invention and not for limiting it.

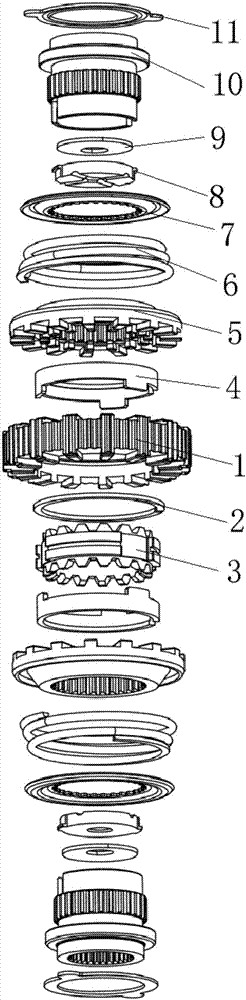

[0013] A limited-slip differential assembly, including a double-sided gear 1 and two sets of semi-differential devices symmetrically arranged on both sides of the double-sided gear 1, the semi-differential device includes a center collar 2, a center tooth 3, a card Ring 4, tooth surface device 5, spring 6, shrapnel ring 7, friction plate 8, washer 9, side shaft gear 10 and wing spacer 11, two collars 4 are connected through the center collar 2 and the center tooth 3, The two collars 4 are connected by the central collar 2, the side of the central tooth 3 is provided with a bar-shaped groove, and the side wall of the collar 4 is provided with a protrusion matching the bar-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com