Oil seal assembly and second-order seam allowance sealing structure for supporting wheel bearing of paddy field tractor

A track roller shaft and tractor technology, which is applied in the field of tractors, can solve the problems of reducing the service life of track rollers, affecting the normal operation of wheel trains, and failure of sealing performance, so as to reduce the incidence of failure, prevent muddy water from infiltrating, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

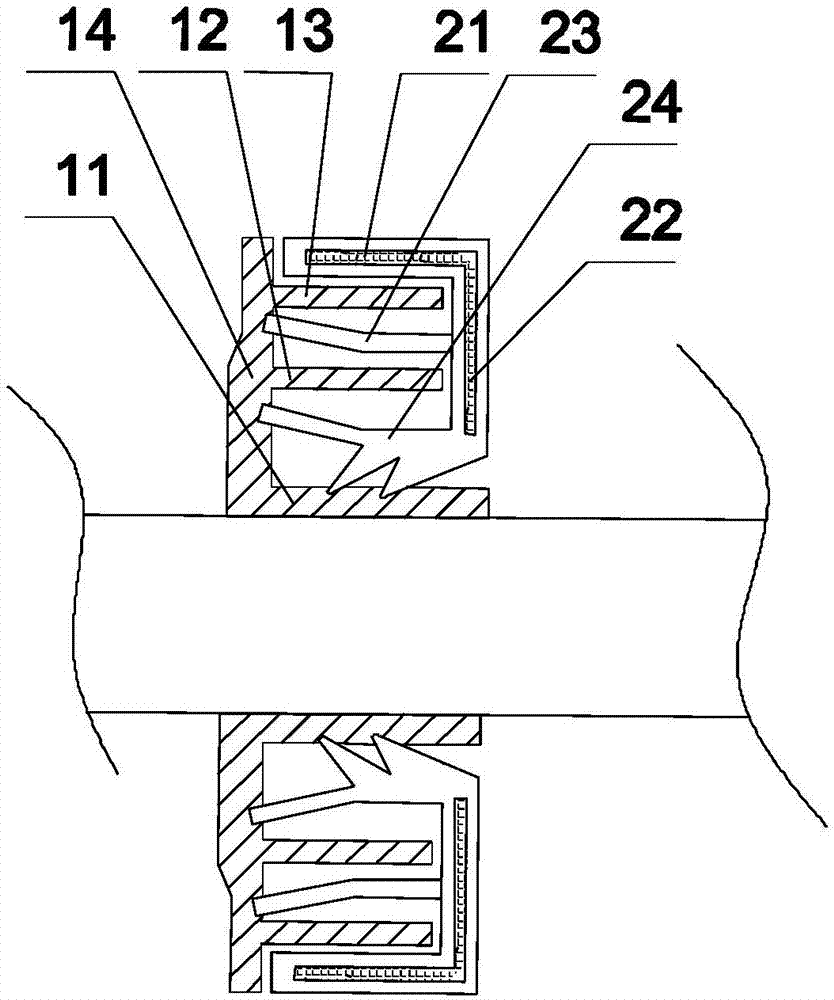

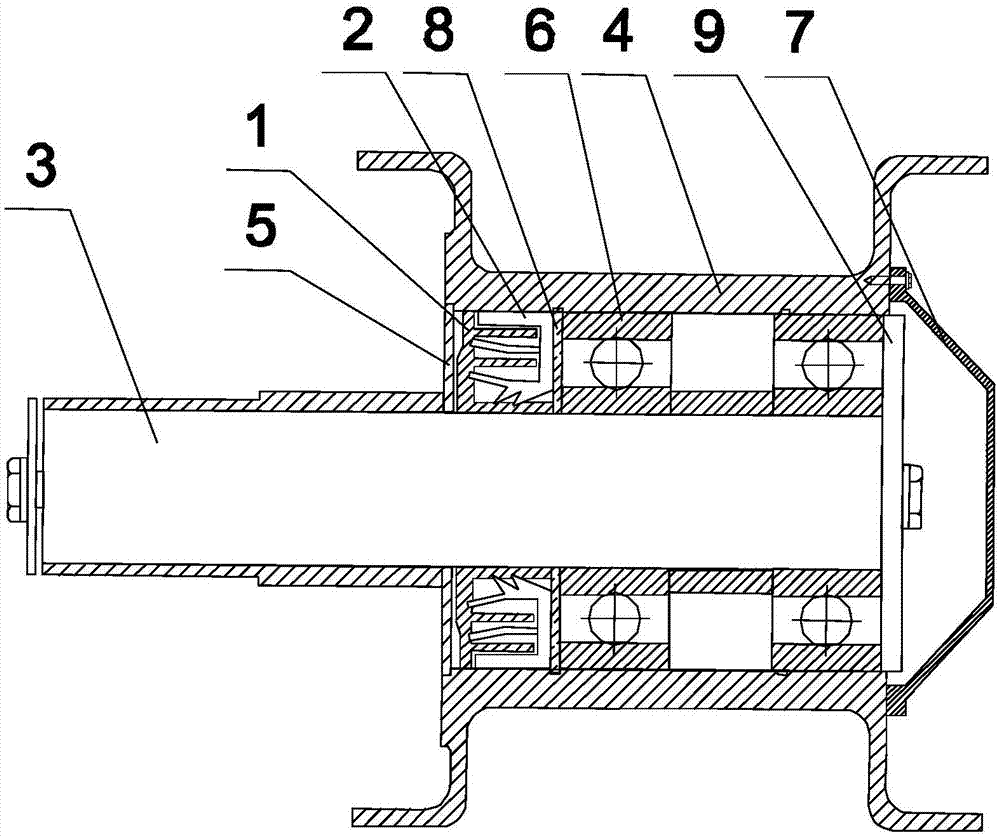

[0025] Such as figure 1 and 2 as shown, figure 1 It is a structural schematic diagram of the oil seal assembly for the roller bearing of the paddy field tractor proposed by the present invention, figure 2 It is a structural schematic diagram of the second-order seam sealing structure for paddy field tractor roller bearings proposed by the present invention.

[0026] refer to figure 1 , the oil seal assembly for roller bearings of paddy field tractors proposed by the present invention and its second-order seam seal structure include: a first oil seal 1 and a second oil seal 2;

[0027] The first oil seal 1 includes a first skeleton and a first rubber vulcanized on the outside of the first skeleton. The first skeleton includes an inner fixing sleeve 11, a first ring body 12, and a second ring body 13. One end of the inner fixing sleeve 11 is provided with a The protruding first support plate 14, the first ring body 12 and the second ring body 13 are sequentially sleeved out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com