Method for on-line compensation of positioning error of a robot assisted by external measurement

A compensation method and robot technology, applied in the field of robots, can solve problems such as time-consuming installation and debugging, sensor position and signal interference, and achieve the effect of being convenient for industrial field application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

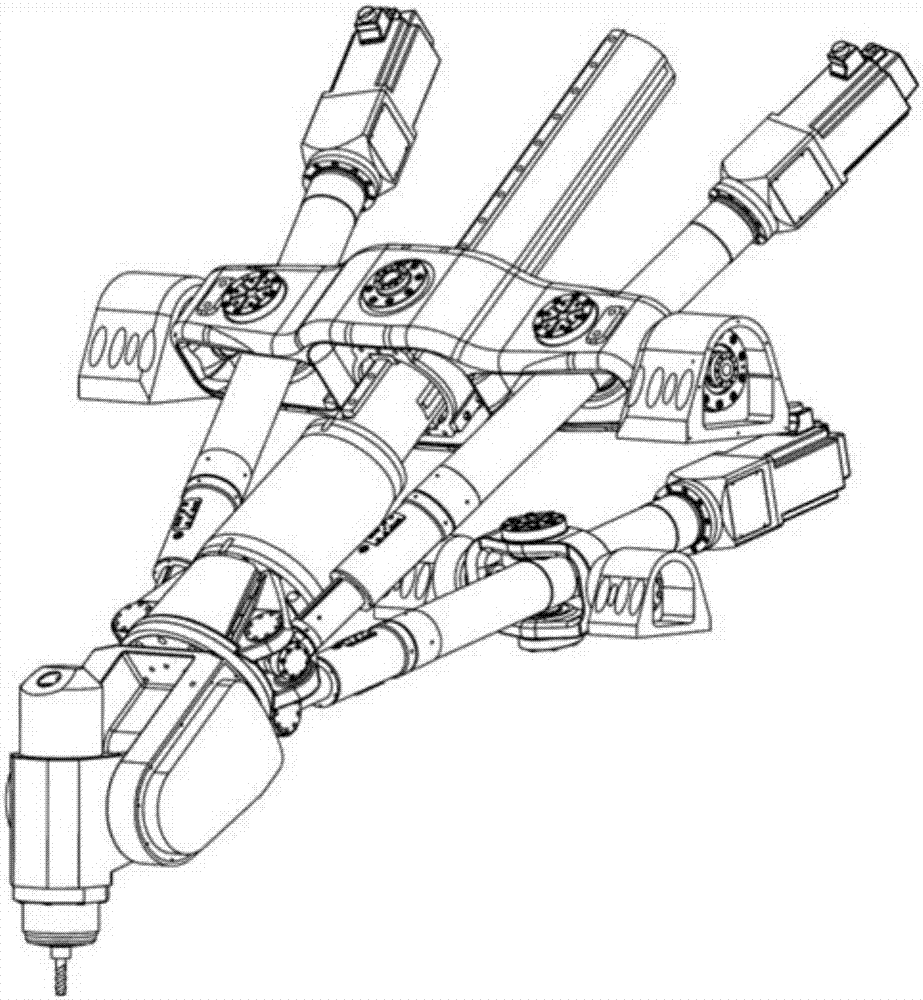

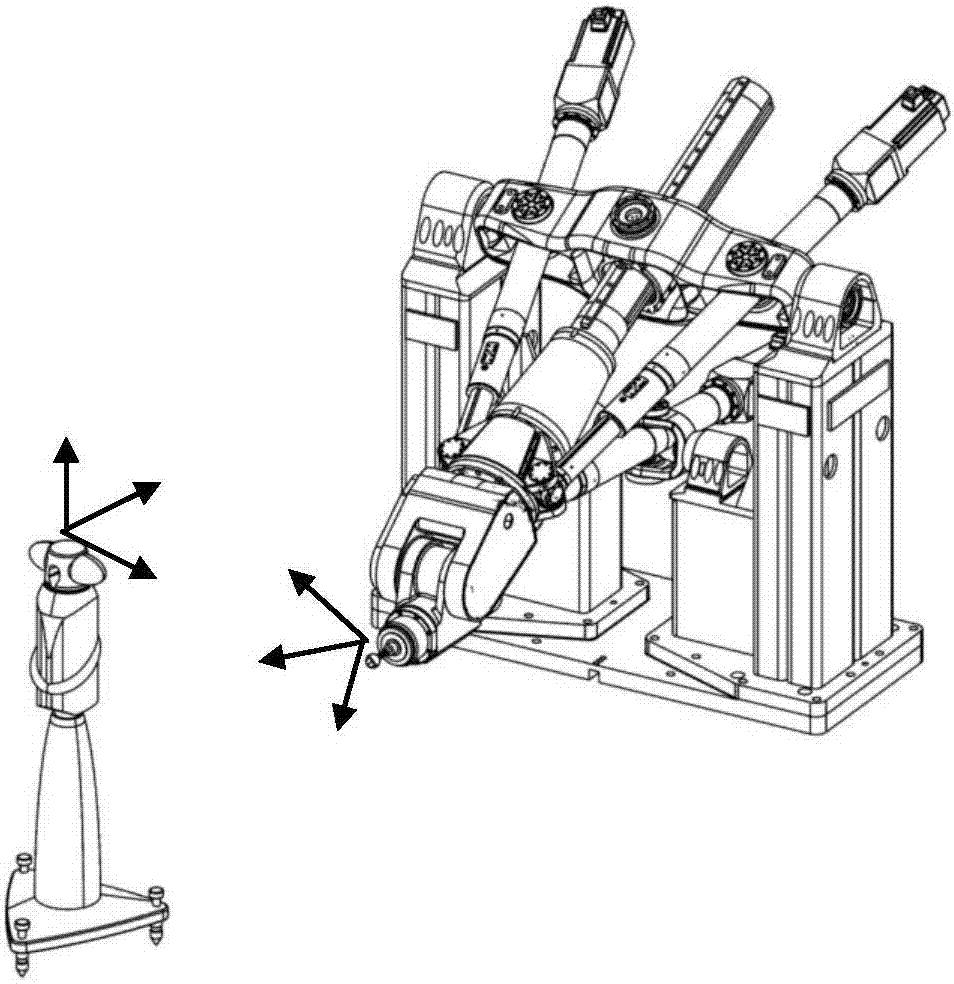

[0026] The online positioning error compensation method of the present invention will be described in detail below in conjunction with a five-degree-of-freedom hybrid robot with a rotating bracket disclosed in Chinese Patent Publication No. CN104985596A.

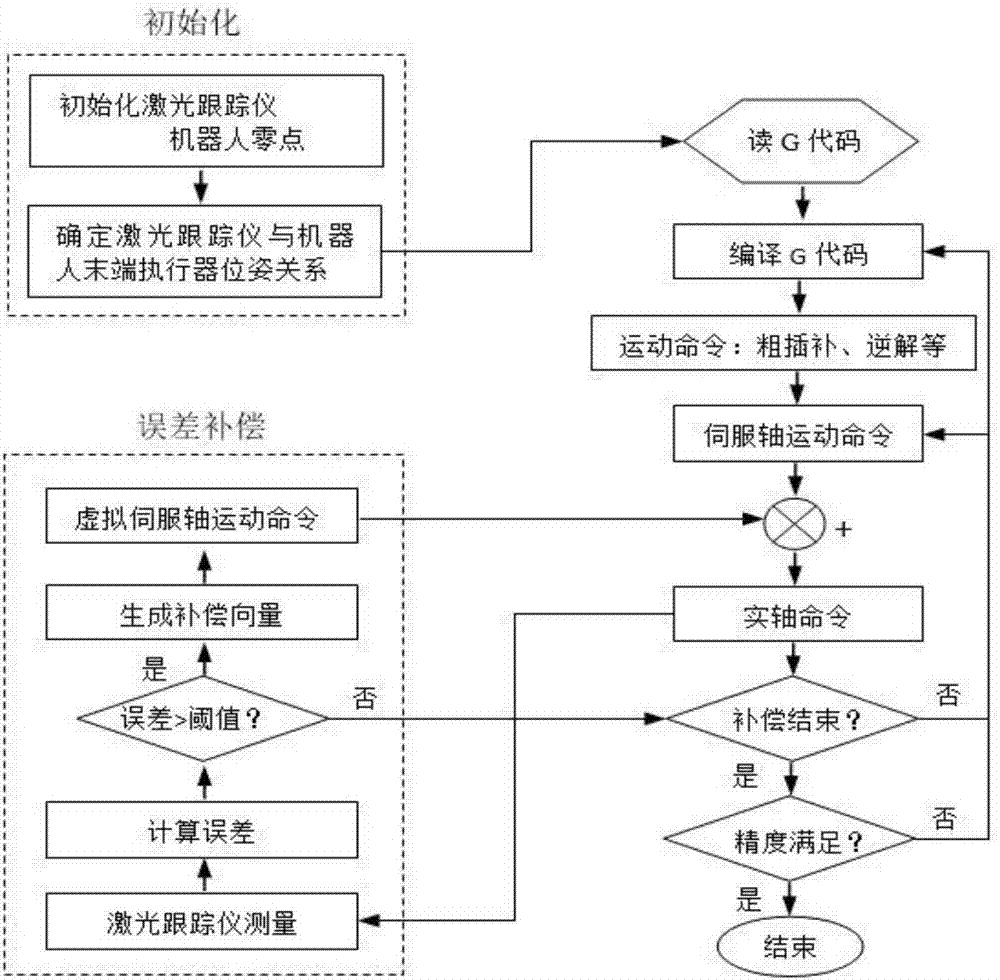

[0027] A method for on-line compensation of robot positioning errors assisted by external measurement of the present invention comprises the following steps:

[0028] (1) The laser tracker is used as the measuring instrument, and the reflective ball of the laser tracker is fixed at the end of the tool of the robot end effector;

[0029] (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com