An electric field-driven device and method for transferring a small amount of high-viscosity glue solution

A high-viscosity, glue-liquid technology, which can be applied to devices and coatings that apply liquid to the surface. It can solve the problems of easy bubbles, residual deterioration of glue, and complicated operation in the syringe, and achieve low consumption of glue and easy operation. Simple, cost-effective production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

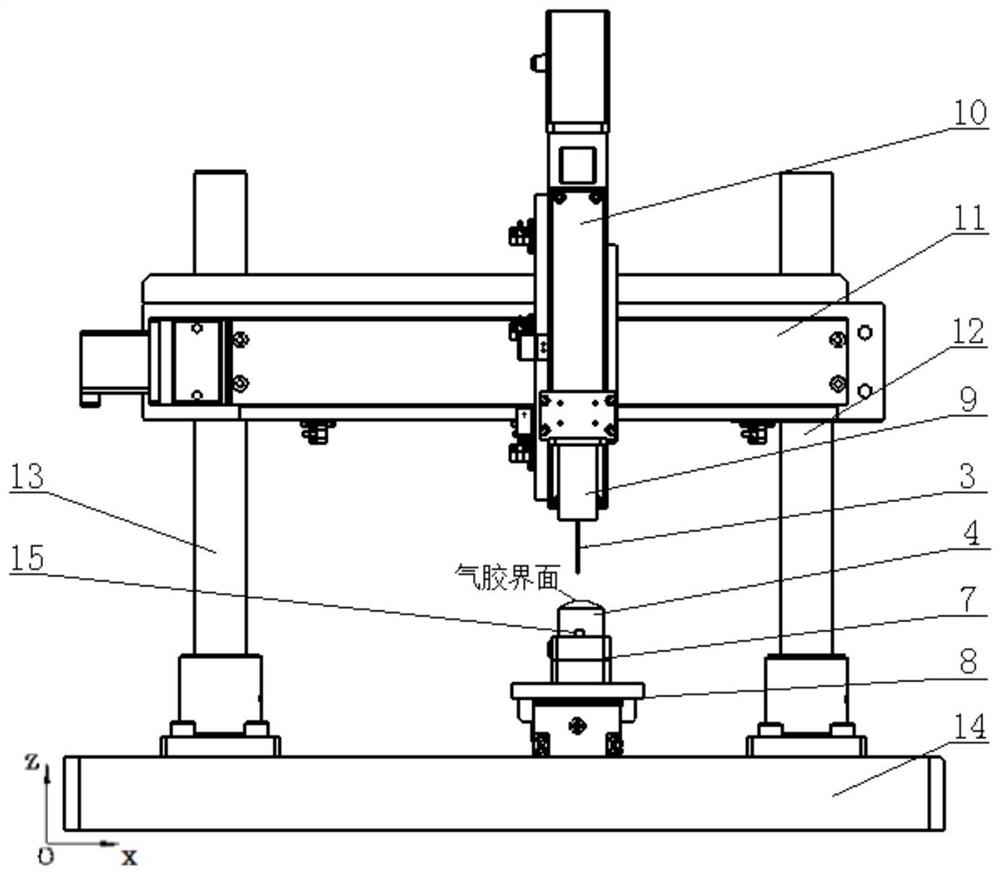

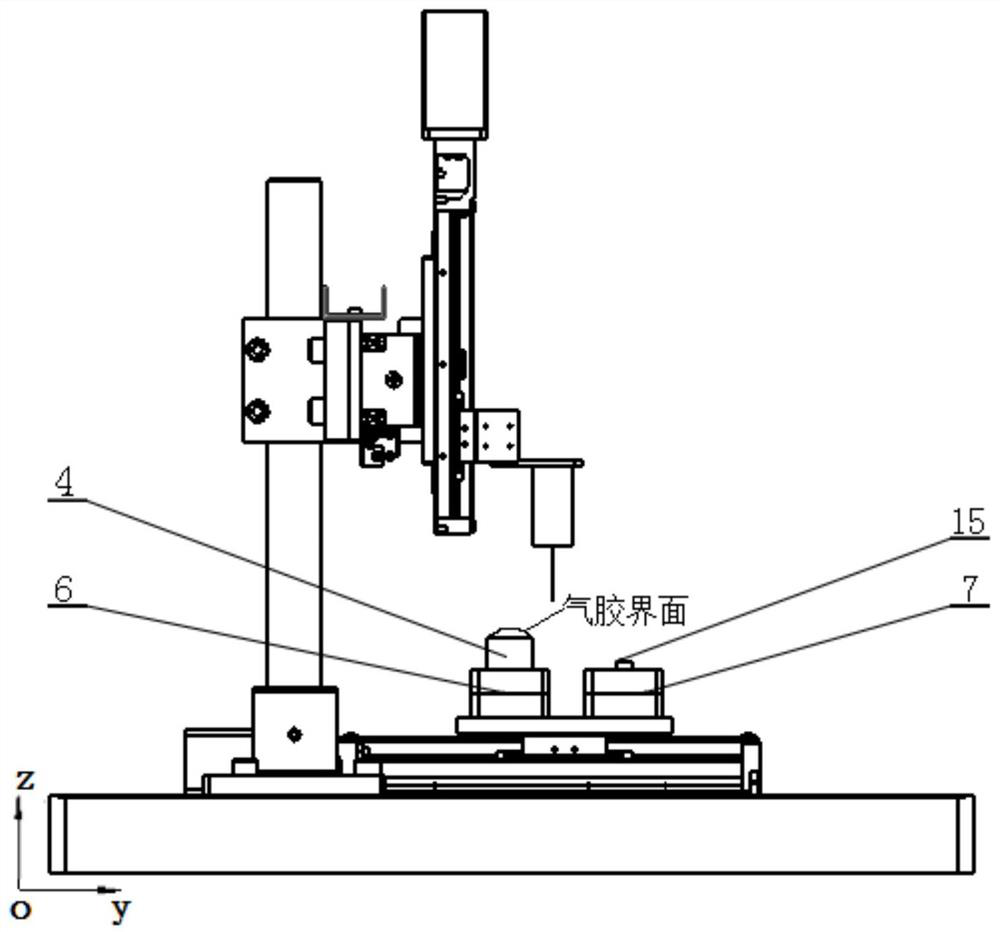

[0022] The technical solutions of the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0023] Taking the nanoliter transfer of epoxy resin glue with a viscosity as high as 70 Pa.s as an example, the specific implementation of the present invention is described in detail as follows in conjunction with the accompanying drawings.

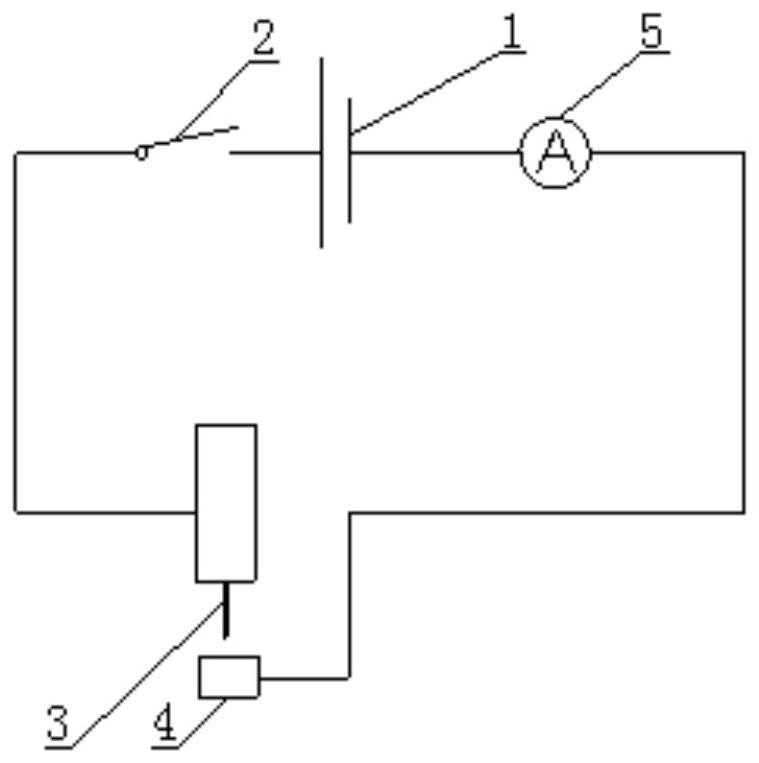

[0024] figure 1 It shows the control schematic diagram of the micro-volume high-viscosity glue solution transfer device. The electric field control part includes a high-voltage power supply 1, a power switch 2, a dispensing needle 3, a glue storage pool 4, and an ammeter 5. The positive pole of the high-voltage power supply 1 is connected to the power switch 2, the power switch 2 is connected to the dispensing needle 3, and the dispensing needle 3 is perpendicular to the glue surface of the glue storage pool 4, forming a needle-plate electrode structure. The bottom surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com