Determination method of ferrosite content in gold ore pressurized oxidation slag and cyanide slag

A measuring method and technology for oxidizing slag, which are applied in measuring devices, material weighing, instruments, etc., to achieve the effect of convenient industrial field application, accurate and reliable measurement results, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

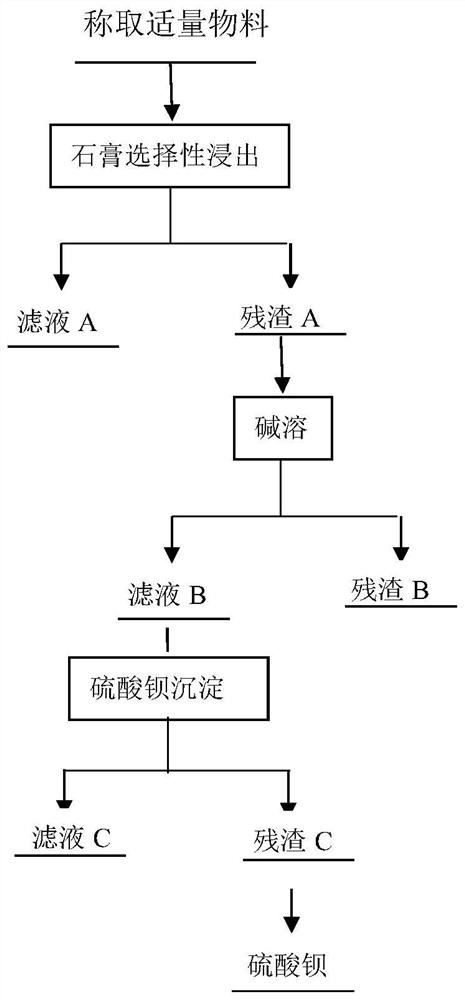

Embodiment 1

[0031] The particle size of gold ore pressurized oxidation slag and cyanide slag is not more than 0.149mm. After fully mixing, bake at 100°C for 2 hours, and then cool to room temperature in a desiccator. Selectively dissolve gypsum, weigh 1.2568g of the material in a 500mL conical flask, add 300mL of 10% sodium chloride solution, leaching for 1.5h by shaking at room temperature, filter, discard the filtrate A, and repeatedly leaching twice until the gypsum in the slag is completely dissolved , to obtain residue A; put residue A in a beaker, add 150mL of 10% sodium hydroxide solution, soak at 90°C for 1.5h, filter, wash with distilled water for 5 to 7 times, collect filtrate B in a beaker, and after acidification, wash with 10% chlorine Precipitate the barium chloride solution, let it stand for 4 hours, filter, dry the residue C, and calcinate to constant weight at 800°C to obtain barium sulfate weight: 0.2602g. The molecular formula of Jarosite in the slag phase is confirmed ...

Embodiment 2

[0033] The particle size of the gold ore pressurized oxidation slag and cyanide slag is not more than 0.149mm. After fully mixing, bake at 100°C for 2 hours, place in a desiccator and cool to room temperature for use. Selectively dissolve gypsum, weigh 2.1231g of the material in a conical flask, add 300mL of 20% sodium chloride solution, leaching for 1 hour by shaking at room temperature, filter, discard the filtrate A, and repeatedly leaching the filter residue A for 3 times until the gypsum in the residue is completely dissolved ;Put the residue A in a beaker, add 200mL 20% sodium hydroxide solution, soak at 95°C for 1 hour, filter, wash with distilled water 5-7 times, discard the residue B, collect the filtrate B in the beaker, after acidification, use 10% Precipitate the barium chloride solution, let it stand for 4 hours, filter, discard the filtrate C, dry the residue C, and calcine at 800°C to constant weight to obtain barium sulfate weight: 0.6712g, and the molecular for...

Embodiment 3

[0035]The particle size of the gold ore pressurized oxidation slag and cyanide slag is not more than 0.149mm. After fully mixing, bake at 100°C for 2 hours, place in a desiccator and cool to room temperature for use. Selectively dissolve gypsum, weigh 3.0010g of the material in a conical flask, add 300mL of 5% sodium chloride solution, shake and leach for 1 hour at room temperature, filter, discard the filtrate A, and repeatedly leach the residue A for 3 times until the gypsum in the slag is completely Dissolve, put residue A in a beaker, add 200mL of 10% sodium hydroxide solution, soak at 85°C for 5 hours, filter, wash with distilled water for 5-7 times, collect filtrate B in a beaker, after acidification, use 10% barium chloride solution for precipitation , let it stand for 4 hours, filter, discard the filtrate C, dry the residue C, and calcinate to constant weight at 800°C to obtain barium sulfate with a weight of 0.1526g. 6 Fe 3 K 0.29 Na 0.69 o 14 S 2 , the molecular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com