Method for measuring content of ferrous sulfate in pressurized oxidizing slag and cyanide slag of gold mine

A technology of oxide slag and ferrite, which is applied in measuring devices, instruments, scientific instruments, etc., to achieve the effects of convenient industrial application, easy-to-purchase and environmental protection of pharmaceuticals, and short method and process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

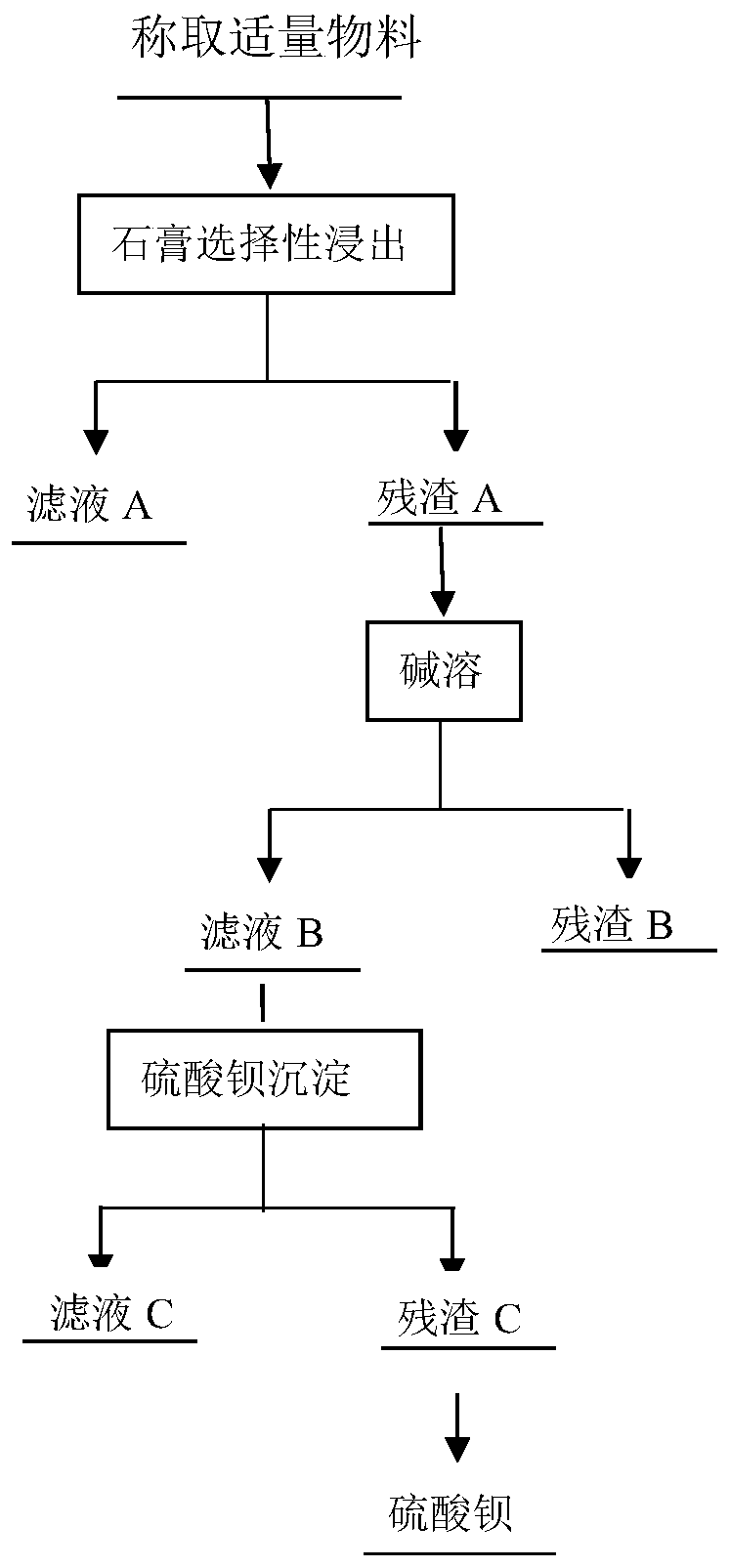

Embodiment 1

[0031] The particle size of gold ore pressurized oxidation slag and cyanide slag is not more than 0.149mm. After fully mixing, bake at 100°C for 2 hours, and then cool to room temperature in a desiccator. Selectively dissolve gypsum, weigh 1.2568g of the material in a 500mL conical flask, add 300mL of 10% sodium chloride solution, leaching for 1.5h by shaking at room temperature, filter, discard the filtrate A, and repeatedly leaching twice until the gypsum in the slag is completely dissolved , to obtain residue A; put residue A in a beaker, add 150mL of 10% sodium hydroxide solution, soak at 90°C for 1.5h, filter, wash with distilled water for 5 to 7 times, collect filtrate B in a beaker, and after acidification, wash with 10% chlorine Precipitate the barium chloride solution, let it stand for 4 hours, filter, dry the residue C, and calcinate to constant weight at 800°C to obtain barium sulfate weight: 0.2602g. The molecular formula of Jarosite in the slag phase is confirmed ...

Embodiment 2

[0033] The particle size of the gold ore pressurized oxidation slag and cyanide slag is not more than 0.149mm. After fully mixing, bake at 100°C for 2 hours, place in a desiccator and cool to room temperature for use. Selectively dissolve gypsum, weigh 2.1231g of the material in a conical flask, add 300mL of 20% sodium chloride solution, leaching for 1 hour by shaking at room temperature, filter, discard the filtrate A, and repeatedly leaching the filter residue A for 3 times until the gypsum in the residue is completely dissolved ;Put the residue A in a beaker, add 200mL 20% sodium hydroxide solution, soak at 95°C for 1 hour, filter, wash with distilled water 5-7 times, discard the residue B, collect the filtrate B in the beaker, after acidification, use 10% Precipitate the barium chloride solution, let it stand for 4 hours, filter, discard the filtrate C, dry the residue C, and calcine at 800°C to constant weight to obtain barium sulfate weight: 0.6712g, and the molecular for...

Embodiment 3

[0035]The particle size of the gold ore pressurized oxidation slag and cyanide slag is not more than 0.149mm. After fully mixing, bake at 100°C for 2 hours, place in a desiccator and cool to room temperature for use. Selectively dissolve gypsum, weigh 3.0010g of the material in a conical flask, add 300mL of 5% sodium chloride solution, shake and leach for 1 hour at room temperature, filter, discard the filtrate A, and repeatedly leach the residue A for 3 times until the gypsum in the slag is completely Dissolve, put residue A in a beaker, add 200mL of 10% sodium hydroxide solution, soak at 85°C for 5 hours, filter, wash with distilled water for 5-7 times, collect filtrate B in a beaker, after acidification, use 10% barium chloride solution for precipitation , let it stand for 4 hours, filter, discard the filtrate C, dry the residue C, and calcinate to constant weight at 800°C to obtain barium sulfate with a weight of 0.1526g. 6 Fe 3 K 0.29 Na 0.69 o 14 S 2 , the molecular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com