Combined detection tool of bearing working condition of box type rotating equipment

A rotating equipment and combined detection technology, which is applied in the direction of mechanical bearing testing, etc., can solve problems such as hidden dangers and malignant equipment accidents, bearings that cannot be visually inspected, and production order impacts, etc., to shorten the time of placement and removal, simple and practical structure, and easy selection of production materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

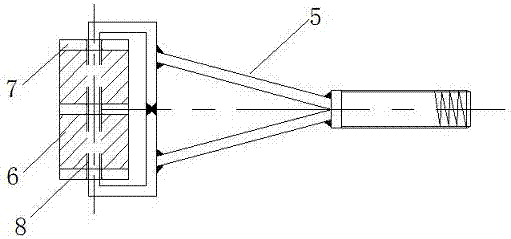

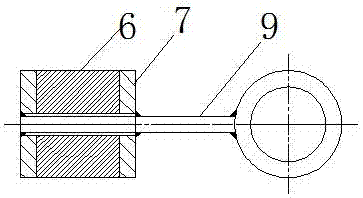

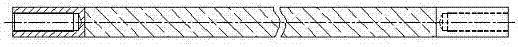

[0021] Figure 1 to Figure 6 It is a schematic diagram of an embodiment of the present invention; as shown in the figure, a box-type rotating equipment bearing working condition combined detection tool of the present invention includes a rolling detection head 1, a fixed detection head 2, a universal adjustment rod 3, and an access hook 4 and a T-shaped hand-held rod 10; the rolling detection head includes a Y-shaped bracket 5, a roller shaft 8, 2 cylindrical hollow magnets 6 and 3 circular metal spacers 7, and the metal spacers 7 are made of stainless steel, and the diameter is the same as that of a cylinder The outer diameter of the hollow magnet 6 is the same; the tail of the Y-shaped support 5 has an external thread, and the ends of the two forks are fixed to a long side of the rectangular frame. The plane where the rectangular frame is located coincides with the plane where the support 5 is located. One long side is the roller shaft 8, and the roller shaft 8 is fixed to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com