Vickers hardness and Rockwell hardness conversion method for 8Cr4Mo4V steel

A technology of 8cr4mo4v and Rockwell hardness, applied in the field of conversion, can solve the problems of error, low data reliability, lack of conversion method between Vickers hardness and Rockwell hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

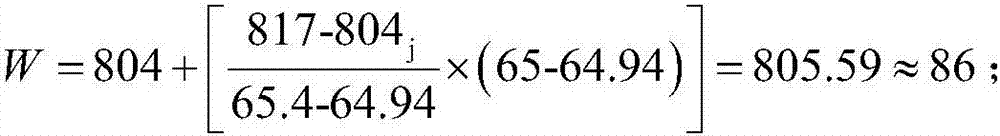

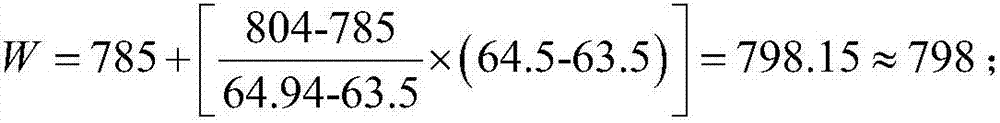

[0024] Specific embodiment one: this embodiment is used for the Vickers hardness of 8Cr4Mo4V steel and the conversion method of Rockwell hardness is carried out according to the following steps:

[0025] 1. Preparation of testing samples:

[0026] ①High hardness value sample: the Rockwell hardness range of the high hardness value sample is 55~63HRC and 63~70HRC; the high hardness value sample with the Rockwell hardness range of 55~63HRC is tempered. 8Cr4Mo4V quenched steel with a Rockwell hardness range of 63 to 70HRC is 8Cr4Mo4V quenched steel with a Rockwell hardness of 63 to 70HRC; 8Cr4Mo4V quenched steel with a Rockwell hardness of 63 to 70HRC

[0027] The tempering process is tempering three times at 550-600° C., and the tempering time is 2-3 hours each time;

[0028] ② Medium hardness sample: select 8Cr4Mo4V quenched steel with a Rockwell hardness of 30-55HRC, and temper the quenched steel as a medium hardness sample; the tempering process is: at a temperature of 600 ° ...

specific Embodiment approach 2

[0039] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the Rockwell hardness tester described in step 2 is calibrated according to the standard ASTM E18 "Standard Test Method for Rockwell Hardness of Metal Materials"; : High hardness value samples use 61.5HRC hardness blocks; medium hardness value samples use 47.6HRC hardness blocks and 35.1HRC hardness blocks; low hardness value samples use 21.6HRC hardness blocks; calibration hardness testers use C standard, The loading load is 150Kgf, the indoor ambient temperature is 10℃~35℃ and the humidity is ≤60%. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0040] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the Vickers hardness tester described in step 2 is calibrated according to the standard ASTM E92 "Metal Material Vickers Hardness Test Method"; the hardness block is selected during calibration The standard is: 743HV1 hardness block is used for samples with high hardness value; 433HV1 hardness block is used for samples with medium hardness value; Humidity is ≤60%. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com